High performance polycarboxylate water reducing agent

A water-reducing agent, high-performance technology, used in the field of concrete admixtures, can solve the problems of affecting concrete strength, remodeling concrete, and high slump loss, achieving small slump loss, preventing segregation, high water reduction rate and adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

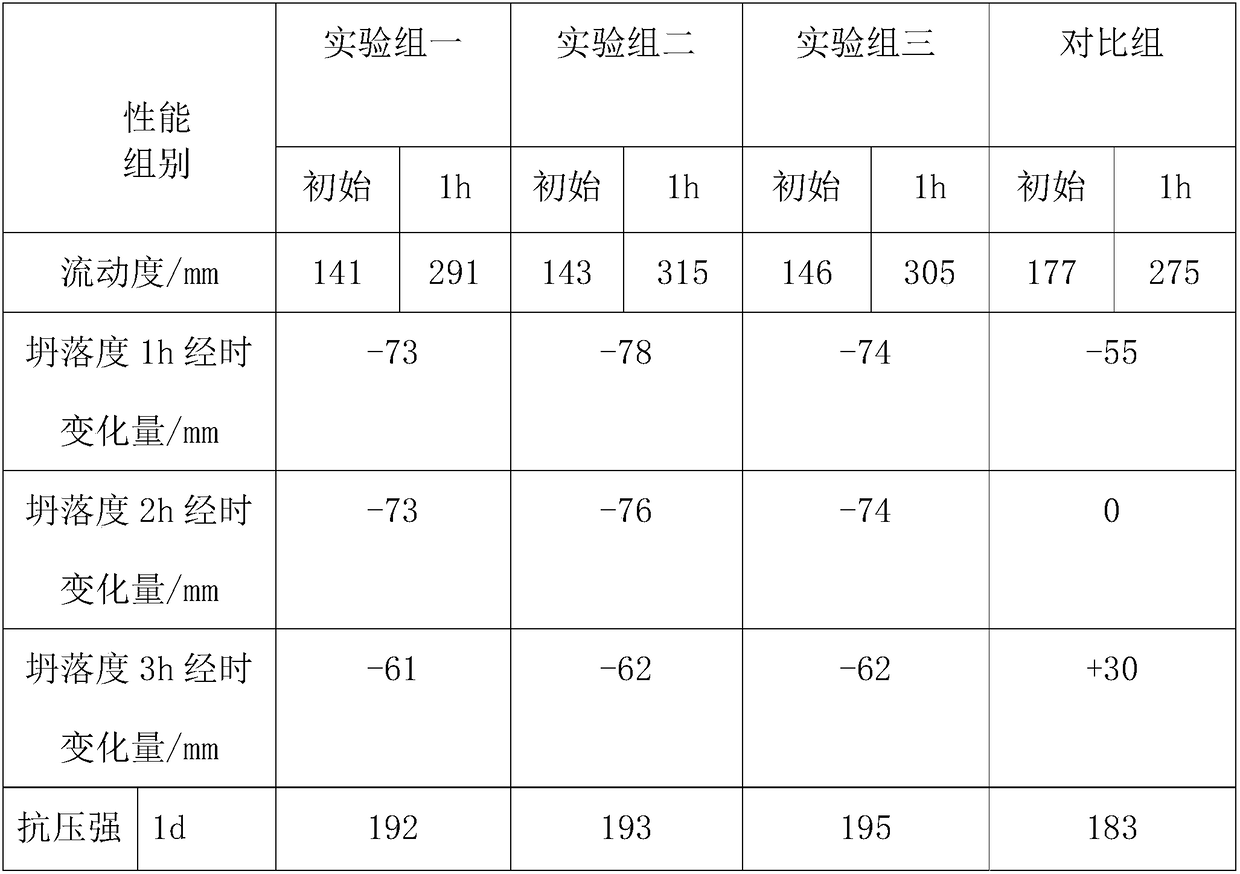

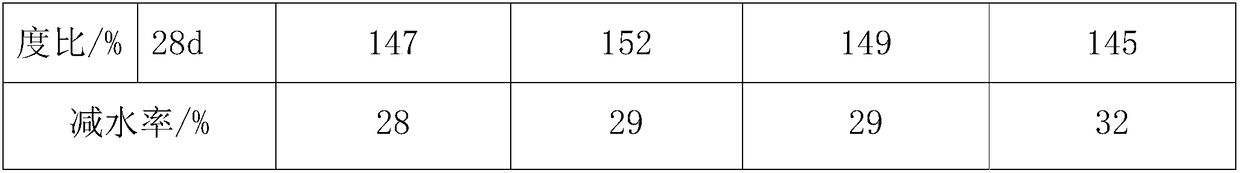

Examples

Embodiment 1

[0021] A polycarboxylic acid high-performance water reducer, made of the following chemical raw materials in proportion by weight: 65 parts of isobutenol polyoxyethylene ether, 36 parts of isopentenol polyoxyethylene ether, 30 parts of alkylphenol polyoxyethylene ether 27 parts, 27 parts of methallyl polyoxyethylene ether, 20 parts of halogenated fatty acid, 17 parts of sucrose ester, 1 part of sodium allyl sulfonate, 4 parts of sodium persulfate, 10 parts of maleic anhydride, 4 parts of tartaric acid, 6 parts of cinnamic acid, 4 parts of sodium hydroxide, 3 parts of thioglycolic acid, 4 parts of triethanolamine and 1 part of thiourea. The maleic anhydride is hydrolyzed polymaleic anhydride with a molecular weight of 550. The allyl sodium sulfonate is prepared by reacting allyl alcohol and sodium methanesulfonate in a reaction kettle, and is a powdery crystal formed by drying. The sodium hydroxide is an unsaturated solution of sodium hydroxide with a concentration of 2.9% and...

Embodiment 2

[0030] A polycarboxylic acid high-performance water reducer, made of the following chemical raw materials in proportion by weight: 50 parts of isobutenol polyoxyethylene ether, 40 parts of isopentenol polyoxyethylene ether, 38 parts of alkylphenol polyoxyethylene ether 32 parts, 32 parts of methallyl polyoxyethylene ether, 35 parts of halogenated fatty acid, 23 parts of sucrose ester, 3 parts of sodium allyl sulfonate, 15 parts of sodium persulfate, 14 parts of maleic anhydride, 6 parts of tartaric acid, 9 parts of cinnamic acid, 16 parts of sodium hydroxide, 5 parts of thioglycolic acid, 15 parts of triethanolamine and 4 parts of thiourea. The maleic anhydride is hydrolyzed polymaleic anhydride with a molecular weight of 550. The allyl sodium sulfonate is prepared by reacting allyl alcohol and sodium methanesulfonate in a reaction kettle, and is a powdery crystal formed by drying. The sodium hydroxide is an unsaturated solution of sodium hydroxide with a concentration of 3.5...

Embodiment 3

[0039] A polycarboxylate high-performance water reducer, made of the following chemical raw materials in proportion by weight: 57.5 parts of isobutenol polyoxyethylene ether, 38 parts of isopentenol polyoxyethylene ether, 34 parts of alkylphenol polyoxyethylene ether 29.5 parts of methallyl polyoxyethylene ether, 27.5 parts of halogenated fatty acid, 19.5 parts of sucrose ester, 2 parts of sodium allyl sulfonate, 9.5 parts of sodium persulfate, 12 parts of maleic anhydride, 5 parts of tartaric acid, 7.5 parts of cinnamic acid, 10 parts of sodium hydroxide, 4 parts of thioglycolic acid, 9.5 parts of triethanolamine and 2.5 parts of thiourea. The maleic anhydride is hydrolyzed polymaleic anhydride with a molecular weight of 550. The allyl sodium sulfonate is prepared by reacting allyl alcohol and sodium methanesulfonate in a reaction kettle, and is a powdery crystal formed by drying. The sodium hydroxide is an unsaturated solution of sodium hydroxide with a concentration of 3.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com