A method for improving the thermal stability of manganese-doped perovskite quantum dots

A technology of quantum dot luminescence and thermal stability, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor devices, etc., to achieve the effects of high transparency, inhibition of agglomeration and growth, and reduction of reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

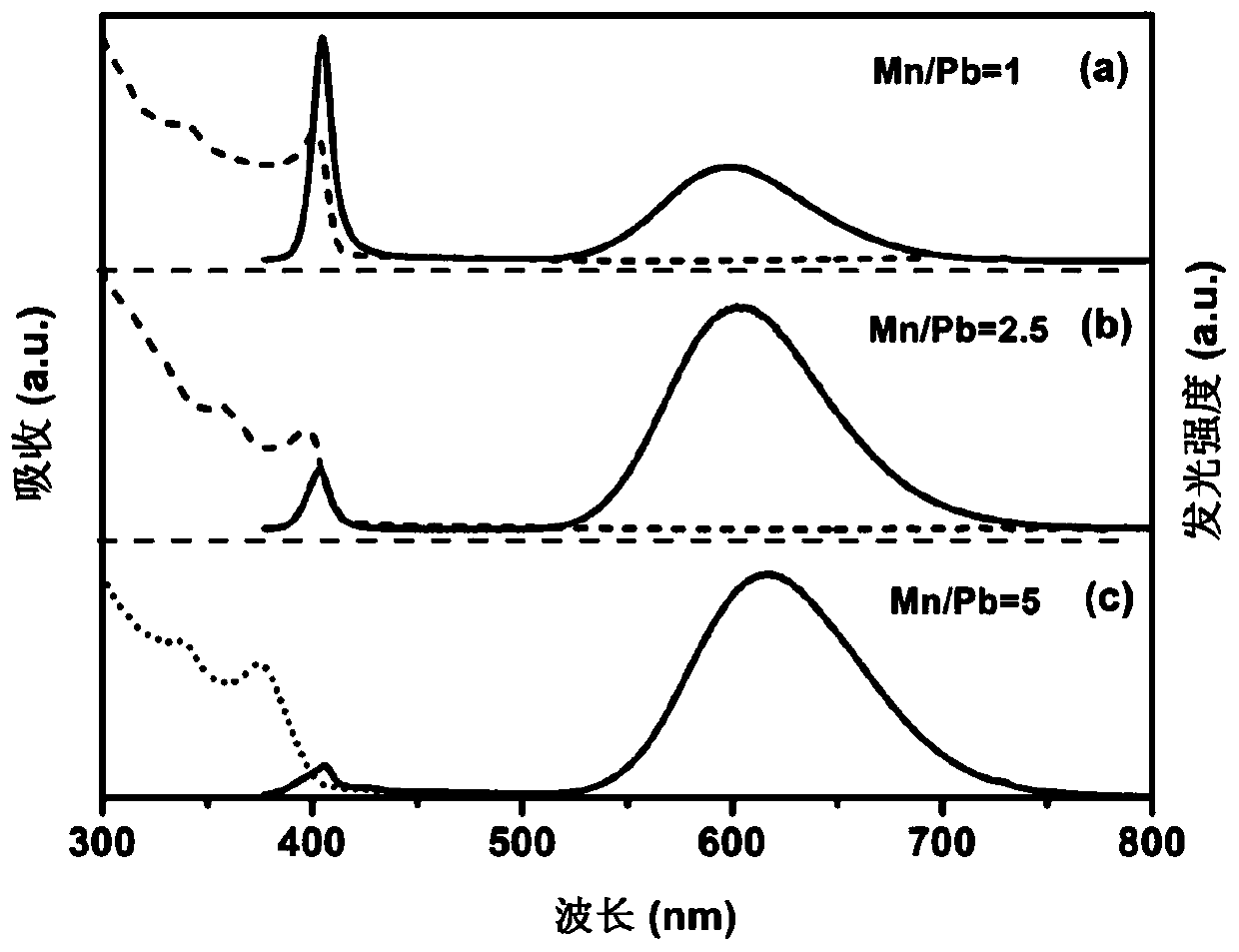

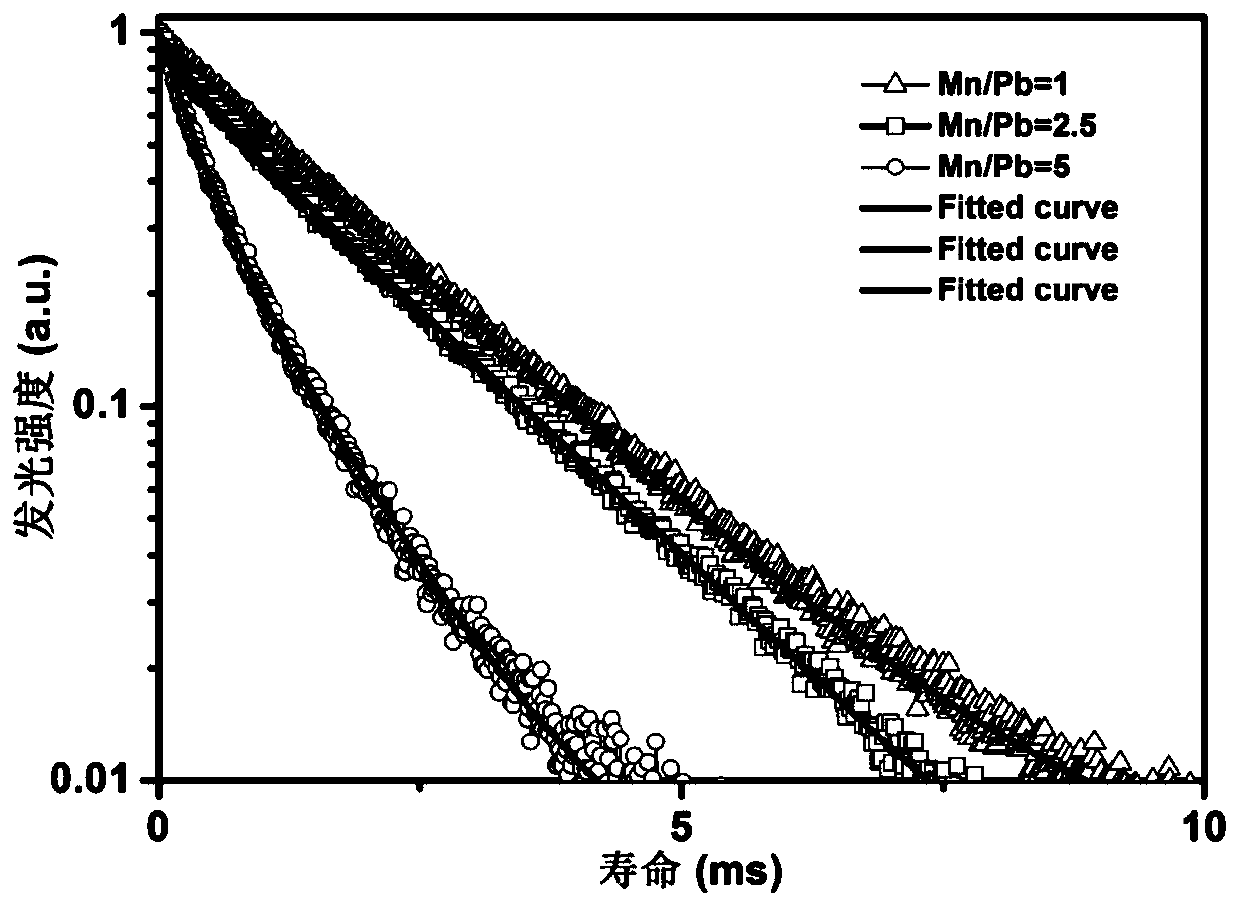

[0046] Example 1 Mn:CsPbCl 3 Preparation of quantum dot solution

[0047] Weigh 0.025g (2mmol) manganese chloride (MnCl 2 ), 0.054g (2mmol) lead chloride (PbCl 2 ) and 5mL octadecene (ODE) were added into a 50mL three-necked flask and mixed to obtain a mixed solution I;

[0048] Under an inert environment, add 1.5mL oleic acid (OA), 1.5mL oleylamine (OAm) and 1mL trioctylphosphine to the above mixed solution I to obtain mixed solution II;

[0049] The high-purity nitrogen atmosphere in the bottle was ensured by repeated vacuuming and nitrogen gas, and the temperature was raised from room temperature to 110°C for 30 minutes to remove the gas in the bottle, and then the temperature was raised to 190°C, and 0.3mL of cesium precursor (oleic acid cesium), keep it for 1min, cool down to room temperature quickly with an ice-water cooling bath to terminate the reaction, and finally centrifuge the reaction solution at 7000 revolutions per minute (rpm) for 5min, remove the supernatan...

Embodiment 2

[0053] Embodiment 2 PDMS injection amount is to Mn:CsPbCl 3 Effect of Quantum Dot Luminescence

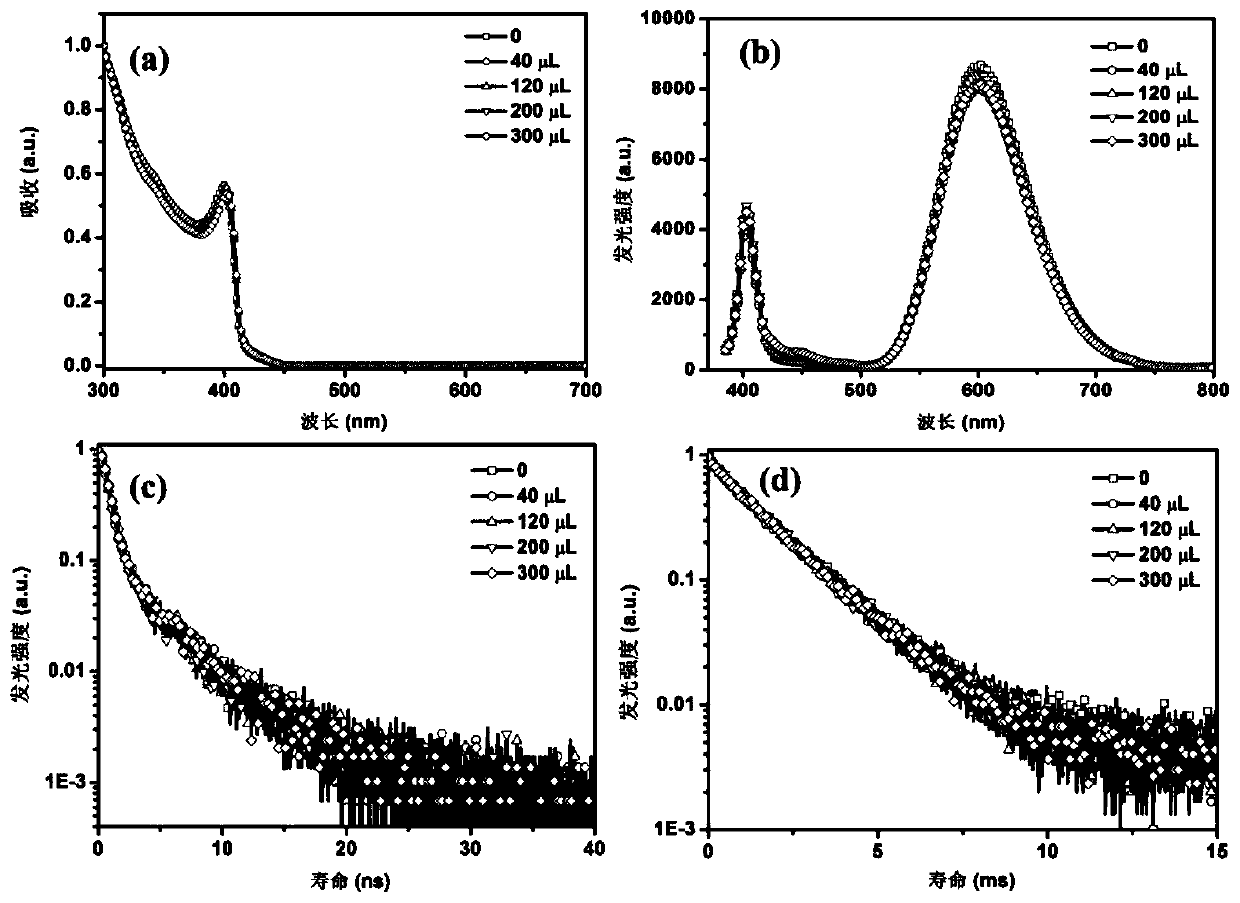

[0054] Take sample B (Mn / Pb=2.5) in Example 1 and dissolve it in a cuvette containing 4mL of n-hexane to ensure that the exciton absorption of the quantum dots is about 0.05 (optical density), and put them in the quantum dot solution in turn Add 0, 40, 120, 200, 300 μL of PDMS solution (PDMS dissolved in n-hexane, 10 mg / mL) to obtain mixed solution III; respectively measure the absorption spectrum, luminescence spectrum, and exciton emission lifetime of mixed solution III at each concentration and Mn 2+ Luminous lifetime.

[0055] image 3 For the PDMS of the embodiment of the present invention 2 different amounts to Mn:CsPbCl 3 Effect of quantum dots on luminescence. Among them, Figures (a)(b)(c)(d) respectively represent injection into PDMS, Mn:CsPbCl 3 Quantum dot luminescence absorption, photoluminescence spectrum and exciton luminescence and Mn 2+ Luminous lifetime. i...

Embodiment 3

[0057] Get 0.2mL (25mg / mL) Mn in Example 1 2+ :CsPbCl 3 Quantum dot B sample was uniformly drop-coated on a silicon wafer cleaned by ultrasonic waves, and placed in a vacuum drying oven at 50°C for 30 minutes, and finally the sample was placed at room temperature to cool, and recorded as a pure quantum dot film sample ( QD).

[0058] Get 0.2mL (25mg / mL) Mn in Example 1 2+ :CsPbCl 3 Quantum dot B sample, add 0.25mL (200mg / mL) of PDMS solution, and the mixed solution is uniformly drop-coated on the silicon wafer cleaned by ultrasonic wave, and placed in a vacuum drying oven at 50°C for 30min, and finally the sample is placed Cooled at room temperature, denoted as PDMS-coated Mn 2+ :CsPbCl 3 Quantum dot film samples (QD / PDMS).

[0059] The above two kinds of quantum dot films were respectively placed in Dewar flasks, vacuumed for 30 minutes, and the corresponding luminescence spectra were measured at intervals of 20K in the temperature range of 293-393K (20-120°C).

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com