Efficient integrated-type automobile radiator assembly structure

A technology of automobile radiator and assembly structure, applied in indirect heat exchangers, vehicle parts, heat exchange equipment, etc., can solve problems such as unfavorable weight reduction and emission reduction, heat exchange failure, large space occupation, etc., to save maintenance and after-sales Cost, increase the heat exchange contact area, and reduce the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

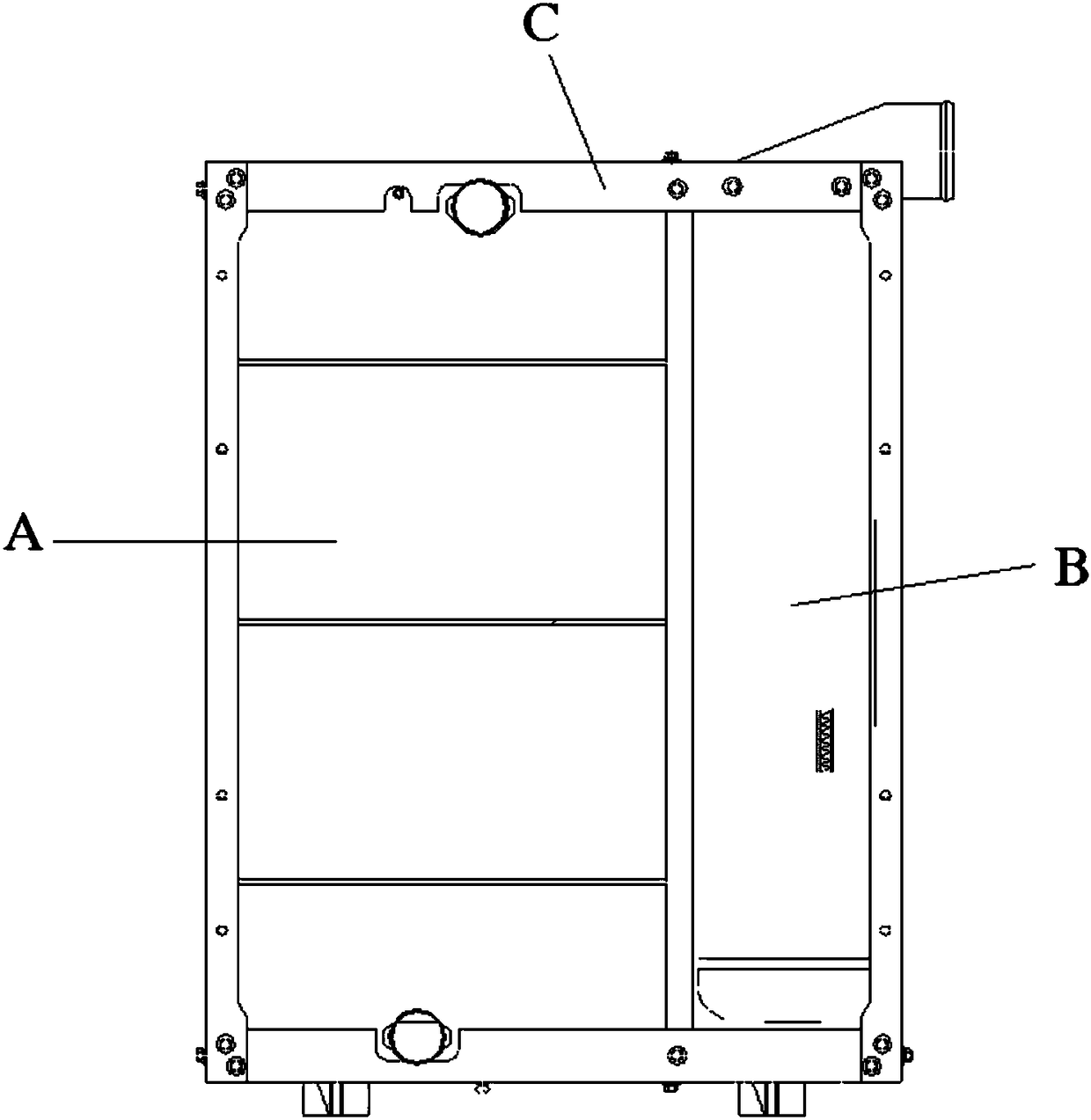

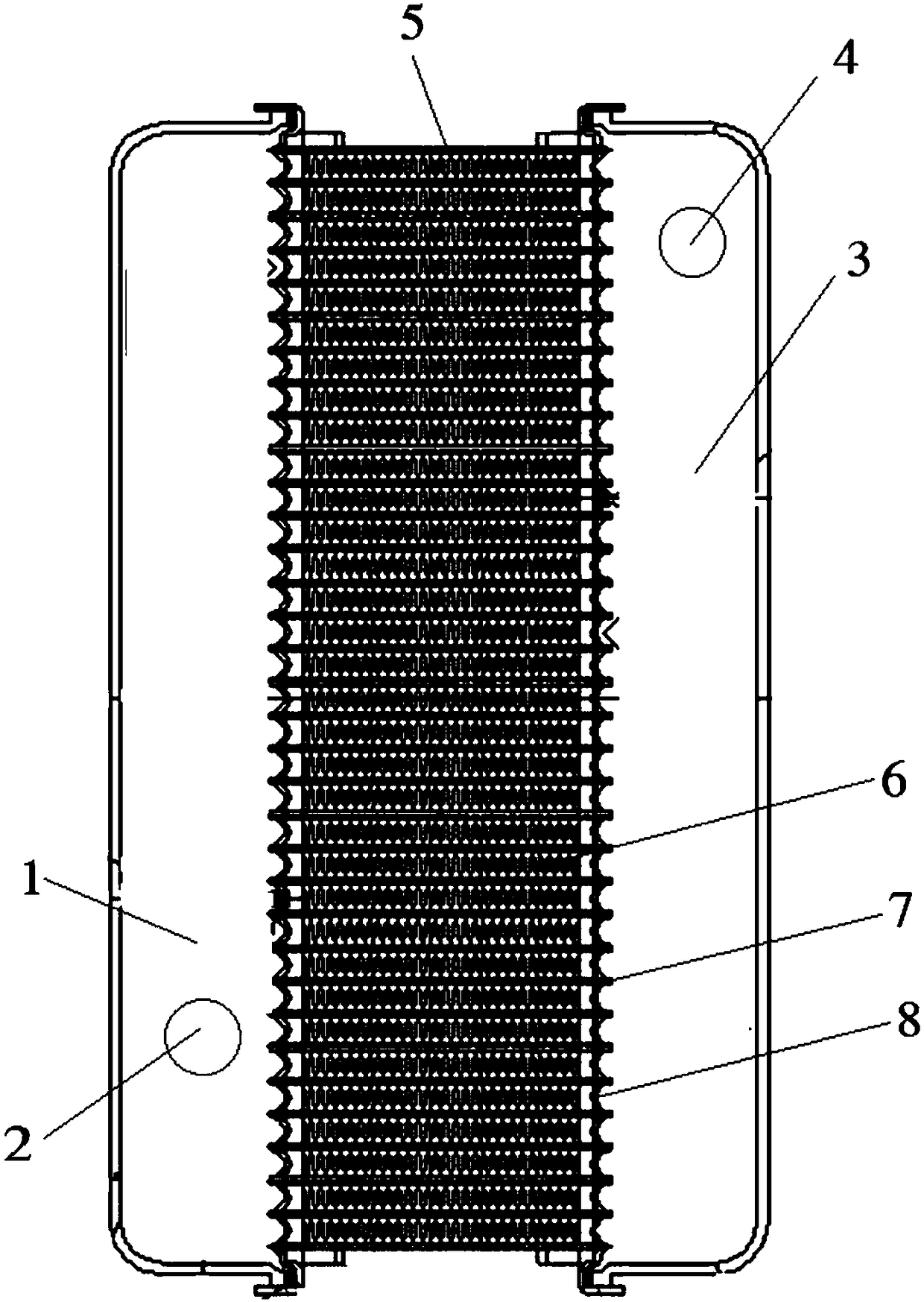

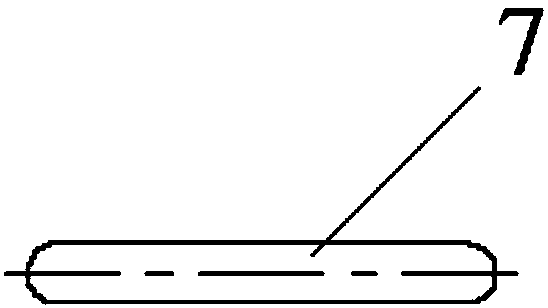

[0024] A high-efficiency integrated car radiator assembly structure, such as figure 1 As shown, it includes frame C, intercooler B and radiator A. The intercooler and radiator A are arranged side by side in the frame B. Rubber cushions are provided at the joints between radiator A and intercooler B and frame C. The intercooler and the radiator are installed firmly and compactly, and play a shock-absorbing role to increase the service life. The sponge strip is pasted between the radiator A and the intercooler B for sealing, which has good sealing performance and high heat transfer efficiency. Radiator A, such as figure 2 As shown, it includes a radiator core 5, a water inlet chamber 1 with a water inlet 2, and a water outlet chamber 3 with a water outlet 4. The radiator core 5 is located between the water inlet chamber 1 and the water outlet chamber 3, including the main Sheet 8, radiating pipe 7 and radiating band 6, radiating pipe 7 adopts flat tube, as image 3 As shown, ...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1. The width of the flat tube is 14 mm, and the thickness is 2 mm. The water inlet chamber 1 and the water outlet chamber 3 are stamped by a mold using copper plates. The thickness of the copper plates is 1.1 mm. 7 The flange height of the welding hole is 7mm, the thickness of the radiator core 5 is 60mm, the window opening angle of the heat dissipation strip 6 is 27°, and the wave height is 8mm.

Embodiment 3

[0032] This embodiment is basically the same as Embodiment 1, the width of the flat tube is 18mm, and the thickness is 3mm. 7 The flange height of the welding hole is 9mm, the thickness of the radiator core 5 is 80mm, the opening angle of the heat dissipation strip 6 is 30°, and the wave height is 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com