Straw biomass container and preparation method thereof

A biomass and straw technology, applied in the field of container manufacturing, can solve the problems of unfavorable promotion, high energy consumption, weak mechanical strength, etc., and achieve the effects of improving steam explosion effect, uniform mixing efficiency and high mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0044] Embodiment 1-2, comparative example 1-5

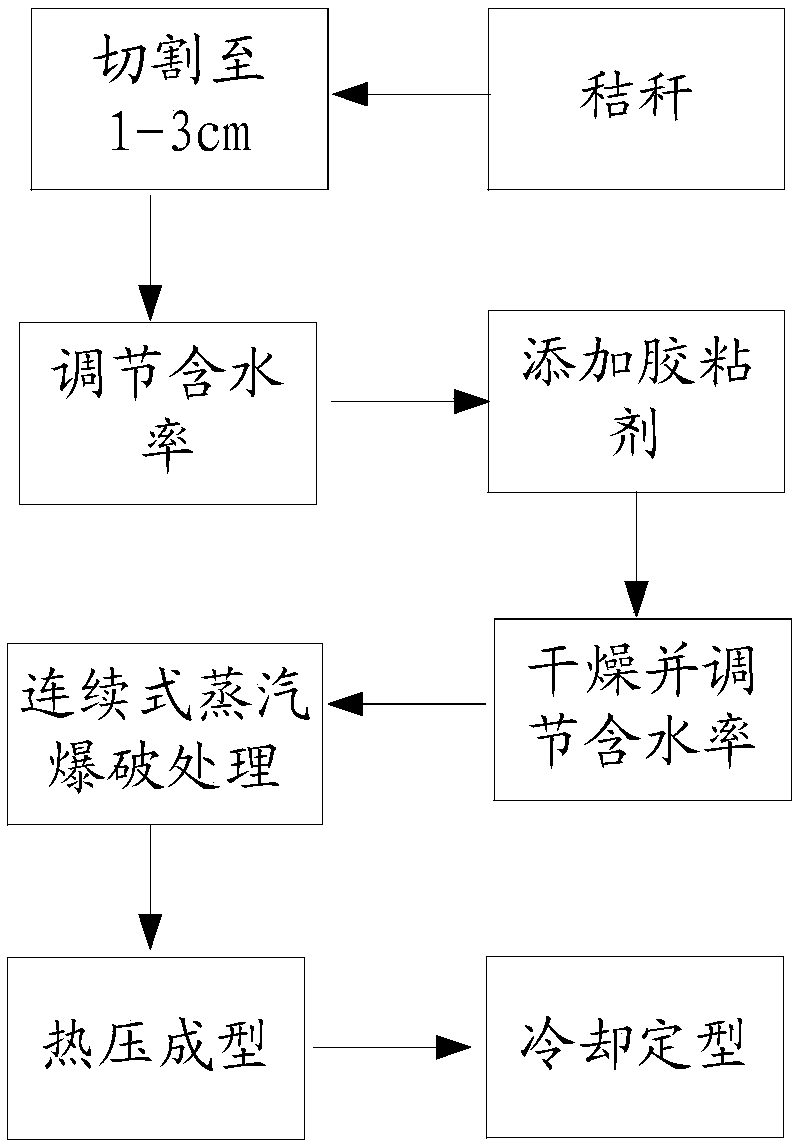

[0045] The invention provides a method for preparing a straw biomass container, comprising the following steps, the process parameters corresponding to each embodiment or comparative example are shown in Table 1, and the process flow is as follows: figure 1 shown.

[0046] (1) Humidity conditioning treatment:

[0047] Take the naturally air-dried rice straw, use a grass cutter to cut the straw to 1-3cm, weigh the straw, add the corresponding quality of tap water, put it into the mixer, adjust the moisture content of the straw, and seal it Place in the bag for a certain period of time;

[0048] (2) Steam explosion pretreatment:

[0049] Put the humidity-adjusted rice straw into a screw steam explosion machine for steam explosion. After measurement, the explosion parameters are temperature 110-150°C, pressure 0.5-2MPa, and steam-exploded rice straw fibers are obtained, which are dried in an oven , and adjust the moisture conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com