UV delay-cured conductive silver adhesive and preparation method thereof

A technology of conductive silver glue and epoxy resin, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of high price, slow curing speed, and few types of oligomers and reactive diluents, and achieve Excellent performance and the effect of overcoming poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0043] (1) Preparation of semi-finished base material:

[0044] 20 parts of alicyclic epoxy resin containing 40% nano-silica, 10 parts of urethane acrylate CN-8004, 110 parts of flake silver powder, 20 parts of nano-rod silver powder, after stirring and dispersing the above materials at 1500 rpm Carry out three-roller grinding until the fineness is below 10um to make a semi-finished base material.

[0045] (2) Preparation of conductive silver glue:

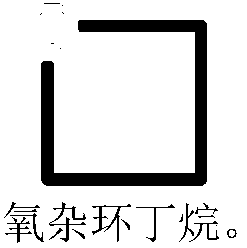

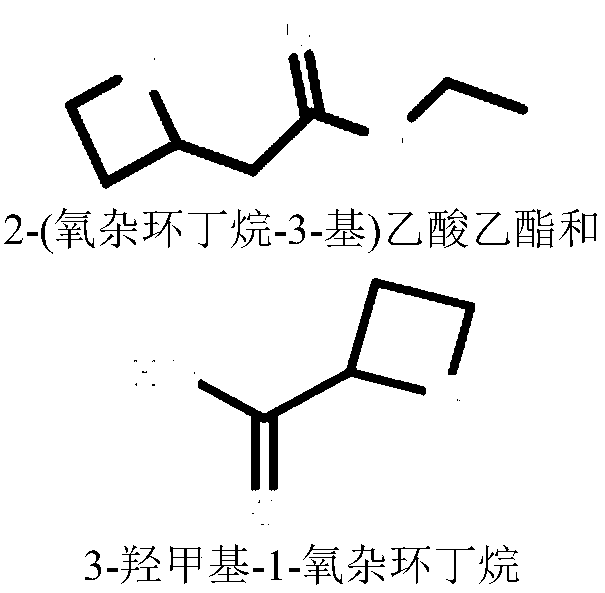

[0046] 160 parts of semi-finished base material in (1), 5 parts of ethyl 2-(oxetan-3-yl) acetate, 4.5 parts of iodonium hexafluorophosphate, 20 parts of self-made photosensitizer, KH-560 coupling 1 part of the agent, after stirring the above materials at 1000 rpm to disperse evenly, defoam at -0.1MPa for 5 to 10 minutes to obtain the delayed curing conductive silver glue.

no. 2 Embodiment

[0048] (1) Preparation of semi-finished base material:

[0049] 20 parts of cycloaliphatic epoxy resin containing 40% nano-silica, 10 parts of acrylate epoxy resin CN-151, 110 parts of flaky silver powder, 20 parts of nano-rod silver powder, stir and disperse the above materials at 1500 rpm After uniformity, carry out three-roll machine grinding, and finally until the fineness is below 10um, it is made into a semi-finished base material.

[0050] (2) Preparation of conductive silver glue:

[0051]160 parts of semi-finished base material in (1), 5 parts of 3-hydroxymethyl-1-oxetane, 4.5 parts of triaryl hexafluorosulfonium antimonate, 20 parts of self-made photosensitizer, titanate coupling 1 part of the agent, after stirring the above materials at 1000 rpm to disperse evenly, defoam at -0.1MPa for 5 to 10 minutes to obtain the delayed curing conductive silver glue.

no. 3 Embodiment

[0053] (1) Preparation of semi-finished base material:

[0054] 20 parts of cycloaliphatic epoxy resin containing 40% nano-silica, 10 parts of acrylate oligomer CN-307, 110 parts of flaky silver powder, 10 parts of nano-rod silver powder, and stir the above materials at 1500 rpm After the dispersion is uniform, it is ground by a three-roll machine until the fineness is below 10um to make a semi-finished base material.

[0055] (2) Preparation of conductive silver glue:

[0056] 160 parts of semi-finished base material in (1), 4.5 parts of ethyl 2-(oxetan-3-yl) acetate, 5 parts of triaryl hexafluorosulfonium antimonate salt, 20 parts of self-made photosensitizer, KH- 1.5 parts of 570 coupling agent, after stirring the above materials at 1000 rpm to disperse evenly, defoaming at -0.1MPa for 5 to 10 minutes to obtain delayed curing conductive silver glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com