Organosilicon hybrid solid-crystal adhesive for light-emitting diodes (LEDs)

A technology of crystal-bonding glue and silicone, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reduced service life, inability to apply, poor yellowing resistance of epoxy groups, etc., to achieve Improve yellowing resistance and weather resistance, avoid cracking in later use, and improve yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

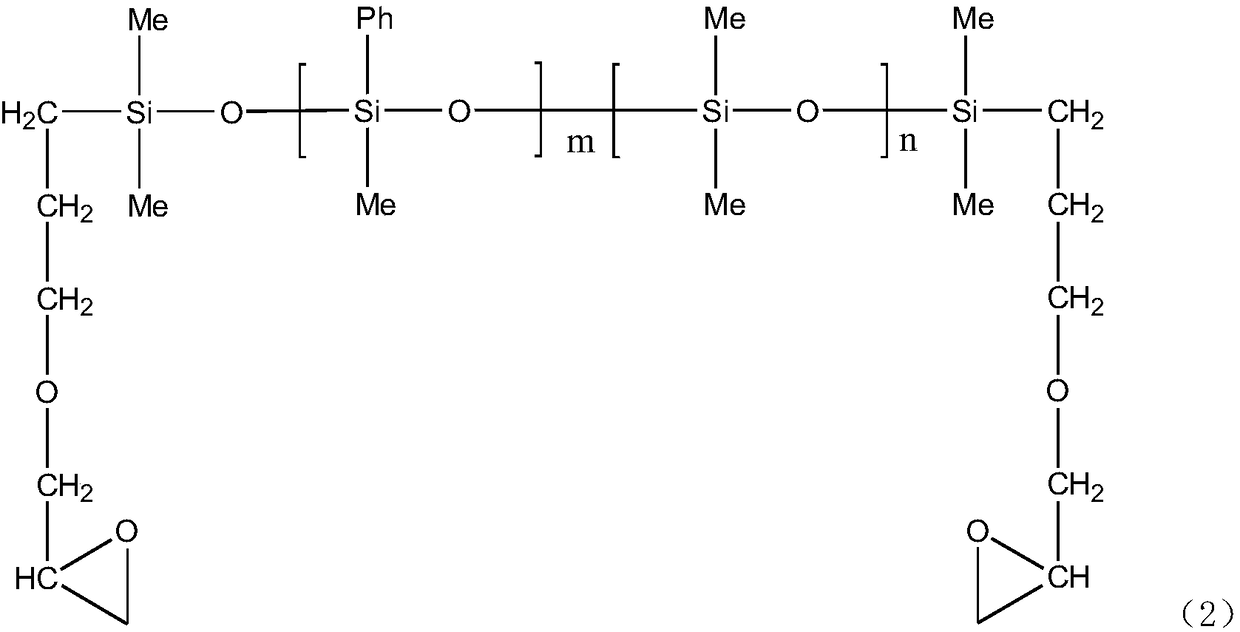

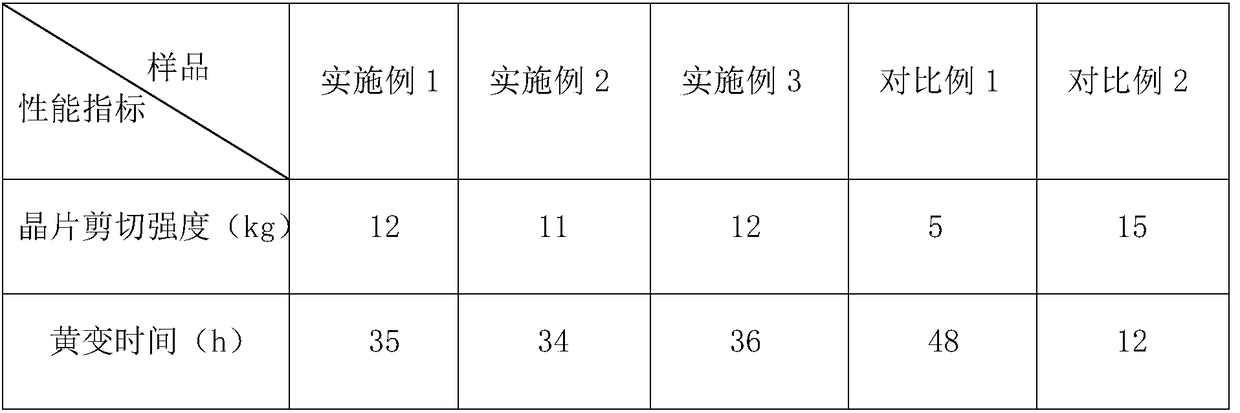

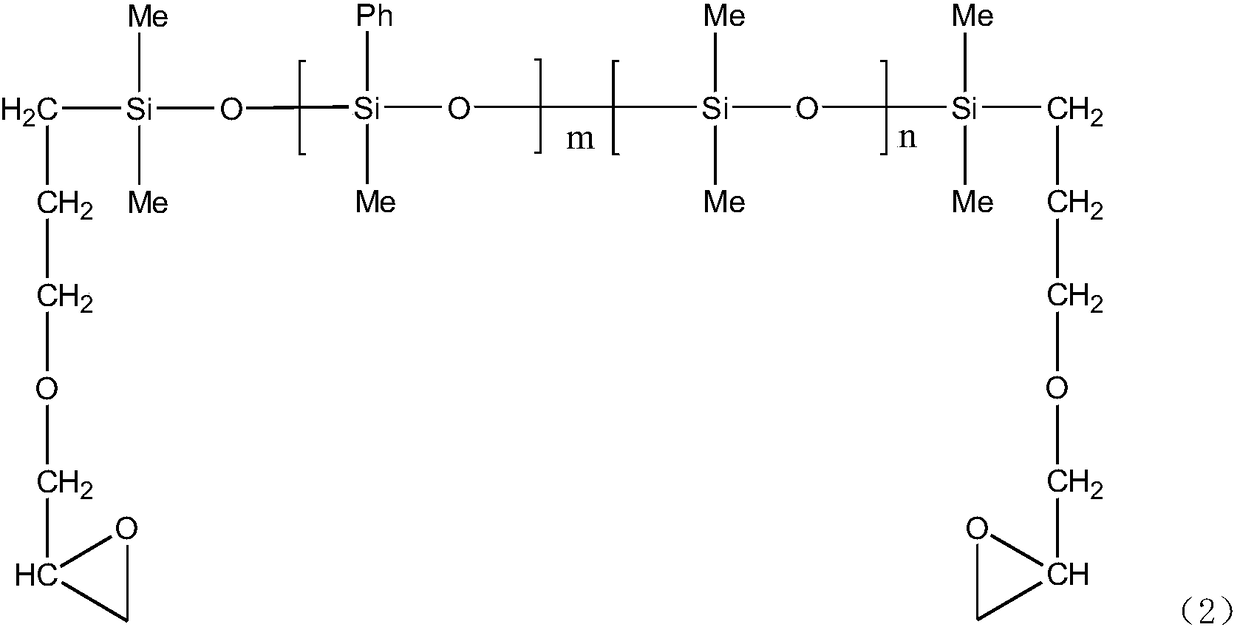

[0034] Take by weighing 63g of epoxy-modified phenyl silicone resin as structural formula (1); 17g of toughening agent as structural formula (2), wherein m=2, n=2; 2-hydroxyl-4-n-octyloxydiphenyl Methanone 0.5g; β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 0.7g; DBU-quaternary phosphonium salt 0.4g; methyl hexahydrophthalic anhydride 1g 2 g of polyhydrogenated-variety-substituted isobenzofuran carboxylic acid, 2 g of R974 white carbon black; add in sequence and mix evenly to obtain silicone crystal-bonding glue.

Embodiment 2

[0036] Weigh 60 g of epoxy-modified phenyl silicone resin such as structural formula (1); 20 g of toughening agent such as structural formula (2), wherein m=3, n=3; 2-(2`-hydroxyl-5'-methanol 0.8g of phenyl)benzotriazole; 0.5g of three (2,4-di-tert-butylphenyl) phosphite; 0.3g of DBU-quaternary phosphonium salt; 0.8g of methyl hexahydrophthalic anhydride; 7g of polyhydrogenated-variety-substituted isobenzofuran carboxylic acid; 1.5g of R974 white carbon black; add in sequence and mix evenly to obtain silicone crystal-bonding glue.

Embodiment 3

[0038] Weigh 58g of epoxy-modified phenyl silicone resin such as structural formula (1); 20g of toughening agent such as structural formula (2), wherein m=4, n=4; 2-(2`-hydroxyl-5'-methanol phenyl) benzotriazole 1g; N,N'-1,6-hexylidene-di-[3,5-di-tert-butyl-4-hydroxyphenylpropanamide 1g; DBU-quaternary phosphonium salt 0.2g; 0.5 g of methylhexahydrophthalic anhydride; 6 g of polyhydro-diversified isobenzofuran carboxylic acid; 1 g of R974 white carbon black; add in sequence and mix evenly to obtain silicone crystal-bonding glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com