LED curing roller painting white primer and preparation method and use method thereof

A white primer and roller coating technology, used in primers, coatings, polyester coatings, etc., can solve the problems of high energy consumption, hidden safety hazards and high temperature of mercury lamps, improve curing speed and toughness, and ensure leveling. Sex, the effect of ensuring fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

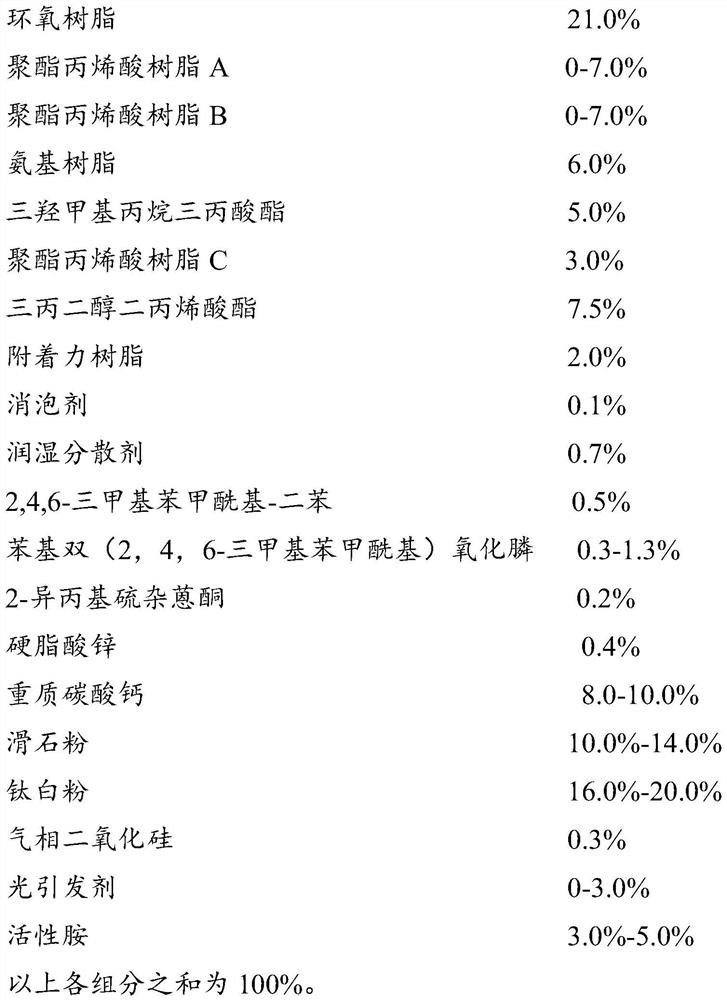

[0027] This embodiment provides a white primer for LED curing roller coating, which consists of the following components in parts by weight:

[0028]

[0029]

[0030] Wherein, the epoxy resin is epoxy acrylate YTM2000M, the polyester acrylic resin A is YTM1506, and the polyester acrylic resin B is YTM1302.

[0031] Wherein, the amino resin is YTM9800.

[0032] Wherein, the polyester acrylic resin C is YTM6601.

[0033] Wherein, the active amine is P113, and the photoinitiator is Jiuri 3124.

[0034] Wherein, the adhesion resin is CMU-22.

[0035] Wherein, the particle size of the talcum powder is 1250 mesh.

[0036] Wherein, the defoamer is Tego-920.

[0037] Wherein, the wetting agent dispersant is BYK111.

[0038] Among them, the specific position of zinc stearate is zinc stearate TV-A.

[0039] Wherein, the titanium dioxide is specifically 895 titanium dioxide.

[0040] Among them, the fumed silica is specifically fumed silica M-5.

Embodiment 2

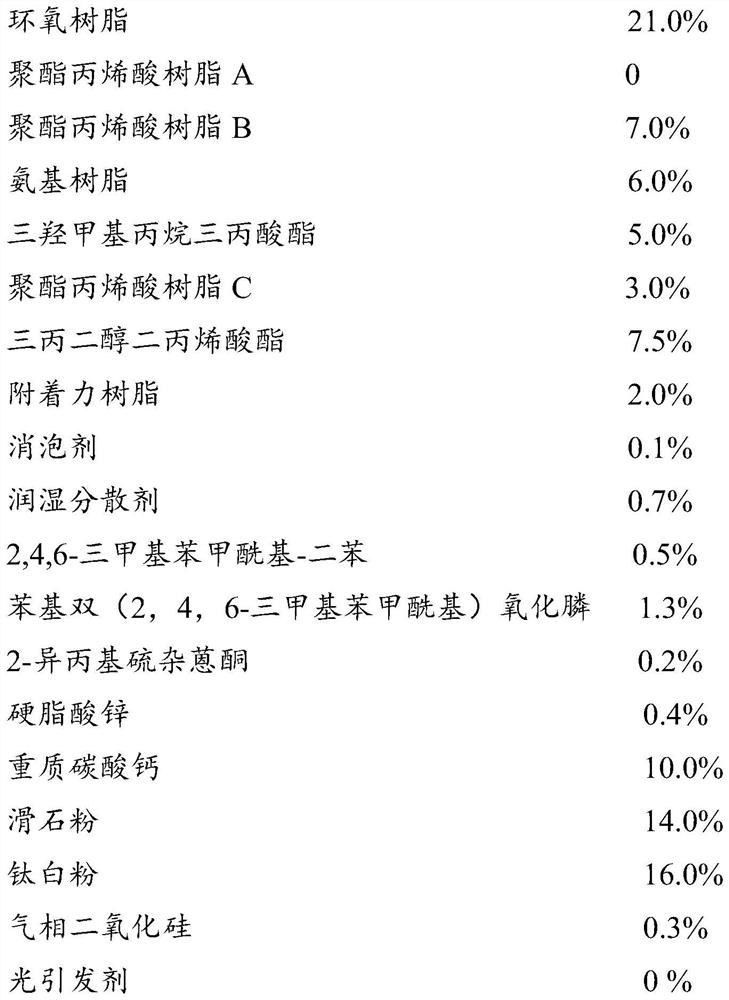

[0042] The difference between a kind of LED curing roller coating white primer of this embodiment and embodiment 1 is that the proportioning of each component is as follows:

[0043]

[0044]

Embodiment 3

[0046] The difference between a kind of LED curing roller coating white primer of this embodiment and embodiment 1 is that the proportioning of each component is as follows:

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com