Three-layer co-extrusion glue-free transparent solar photovoltaic backboard and preparation process thereof

A solar photovoltaic, three-layer co-extrusion technology, applied in the field of solar photovoltaic backplane, can solve the problems affecting the flexibility of the backplane, bending resistance and deformation resistance, unfavorable heat dissipation of solar cells, lack of heat dissipation function design, etc., to achieve favorable Effect of heat dissipation, improvement of thermal conductivity and thermal stability, and high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

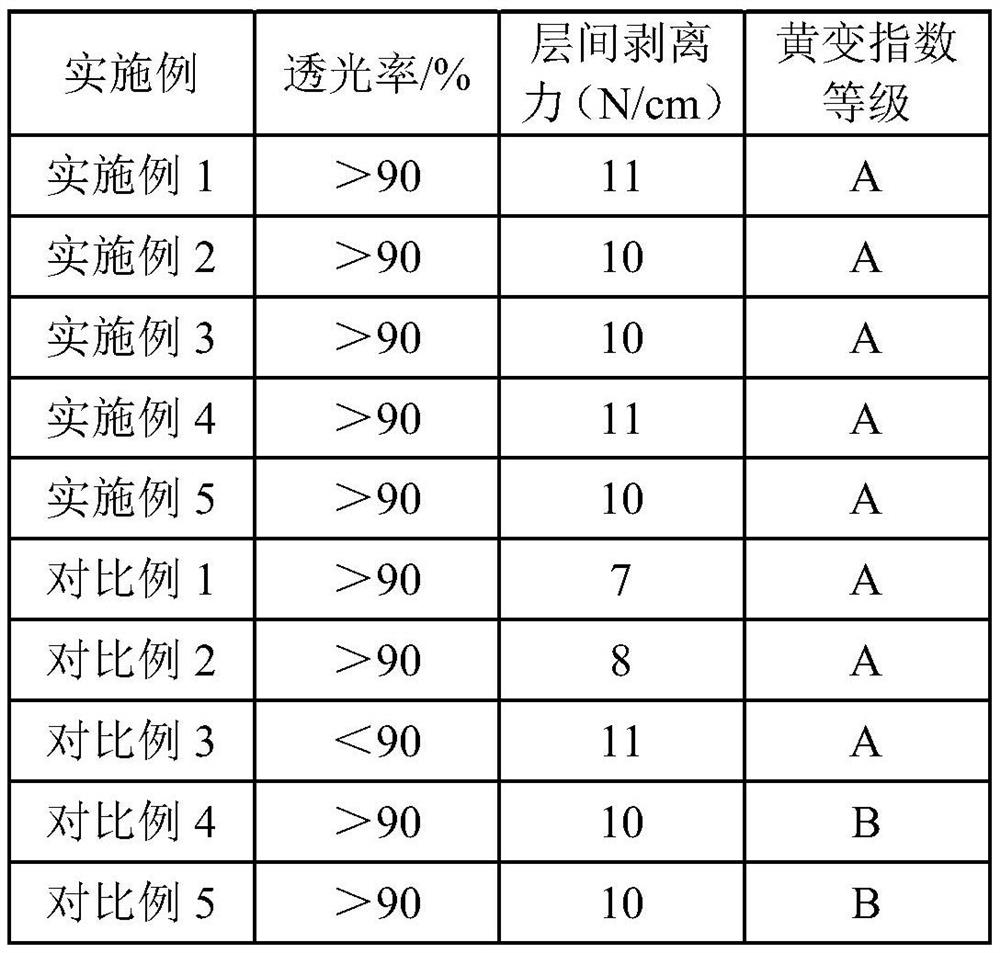

Examples

Embodiment 1

[0038] Embodiment 1 provides a three-layer co-extruded adhesive-free transparent solar photovoltaic backsheet, which includes a transparent inner layer, a transparent middle layer and a transparent outer layer, and the transparent middle layer is located between the transparent inner layer and the transparent outer layer.

[0039] The raw materials for preparing the transparent inner layer include, by weight, 10 parts of LLDPE, 5 parts of LDPE, 75 parts of PP, 0.3 parts of AlN, and 0.3 parts of ethylene methacrylic acid ionomer.

[0040] The raw materials for the preparation of the transparent middle layer include 10 parts of LLDPE, 5 parts of LDPE, 75 parts of PP, 0.3 parts of 2,2,6,6-tetramethyl-4-hydroxypiperidine, 2,2', 0.3 parts of 4,4'-tetrahydroxybenzophenone, 0.3 parts of ethylene methacrylic acid ionomer.

[0041] The raw materials for preparing the transparent outer layer include 10 parts of LLDPE, 5 parts of LDPE, 70 parts of PP and 0.3 parts of ethylene methacrylic...

Embodiment 2

[0052] Embodiment 2 provides a three-layer co-extruded adhesive-free transparent solar photovoltaic backsheet, comprising a transparent inner layer, a transparent middle layer and a transparent outer layer, and the transparent middle layer is located between the transparent inner layer and the transparent outer layer.

[0053] The raw materials for preparing the transparent inner layer include 10 parts of LLDPE, 5 parts of LDPE, 75 parts of PP, 0.3 parts of AlN, and 0.3 parts of ethylene methacrylic acid ionomer in parts by weight.

[0054] The raw materials for the preparation of the transparent middle layer include 10 parts of LLDPE, 5 parts of LDPE, 75 parts of PP, 0.3 parts of 2,2,6,6-tetramethyl-4-hydroxypiperidine, 2,2', 0.3 parts of 4,4'-tetrahydroxybenzophenone, and 0.3 parts of ethylene methacrylic acid ionomer.

[0055] The raw materials for preparing the transparent outer layer include 10 parts of LLDPE, 15 parts of LDPE, 75 parts of PP, and 0.3 parts of ethylene me...

Embodiment 3

[0066] Embodiment 3 provides a three-layer co-extruded adhesive-free transparent solar photovoltaic backsheet, comprising a transparent inner layer, a transparent middle layer and a transparent outer layer, and the transparent middle layer is located between the transparent inner layer and the transparent outer layer.

[0067] The raw materials for preparing the transparent inner layer include, by weight, 10 parts of LLDPE, 5 parts of LDPE, 70 parts of PP, 0.3 parts of AlN, and 0.3 parts of ethylene methacrylic acid ionomer.

[0068] The raw materials for the preparation of the transparent middle layer include 10 parts of LLDPE, 5 parts of LDPE, 70 parts of PP, 0.3 parts of 2,2,6,6-tetramethyl-4-hydroxypiperidine, 2,2', 0.3 parts of 4,4'-tetrahydroxybenzophenone, and 0.3 parts of ethylene methacrylic acid ionomer.

[0069] The raw materials for preparing the transparent outer layer include 10 parts of LLDPE, 5 parts of LDPE, 70 parts of PP and 0.3 parts of ethylene methacrylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com