A kind of polyquaternary ammonium salt inverse demulsifier and preparation method thereof

An inverse demulsifier and multi-quaternary ammonium salt technology, which are used in chemical dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc., can solve the complex preparation process, poor demulsification effect, and low demulsification and dehydration effect. and other problems, to achieve the effect of simple synthesis process and good demulsification and dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

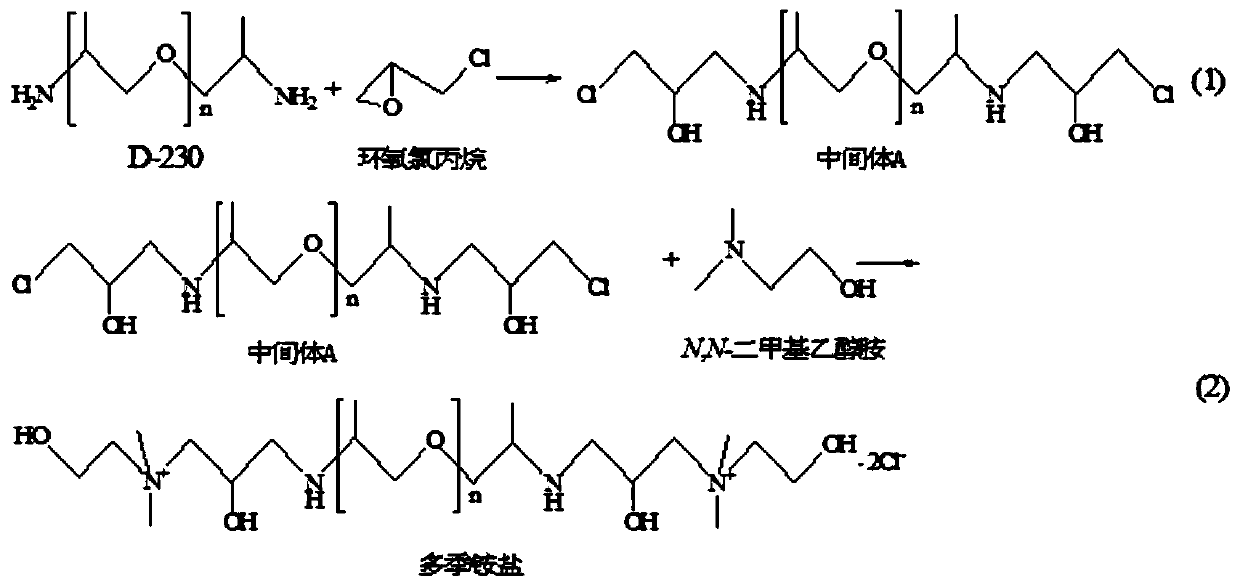

[0012] Add 69g of polyetheramine D-230 into a four-necked flask equipped with a thermometer, a reflux condenser and a stirrer, and slowly add 55.5g of epichlorohydrin dropwise at 40-50°C, n(D-230) / n (Epichlorohydrin) ratio is 1:2. After the dropwise addition, keep warm for 4-5h, raise the temperature to 85-90°C and start adding 53.4g N,N-dimethylethanolamine dropwise, keep warm for 5-6h. The product was purified by absolute ethanol-ethyl acetate and vacuum-dried to obtain a light yellow viscous product, that is, multi-quaternary ammonium salt inverse demulsifier Y-562. See figure 1 .

Embodiment 2

[0014] Add 23g of polyetheramine D-230 into a four-necked flask equipped with a thermometer, a reflux condenser, and a stirrer, and slowly add 74g of epichlorohydrin dropwise at 40-50°C, n(D-230) / n( Epichlorohydrin) ratio is 1:4. After the dropwise addition, keep warm for 4-5h, heat up to 85-90°C and start adding 71.2g of N,N-dimethylethanolamine dropwise, keep warm for 5-6h. The product was purified by absolute ethanol-ethyl acetate and vacuum-dried to obtain a light yellow viscous product, that is, multi-quaternary ammonium salt inverse demulsifier Y-564.

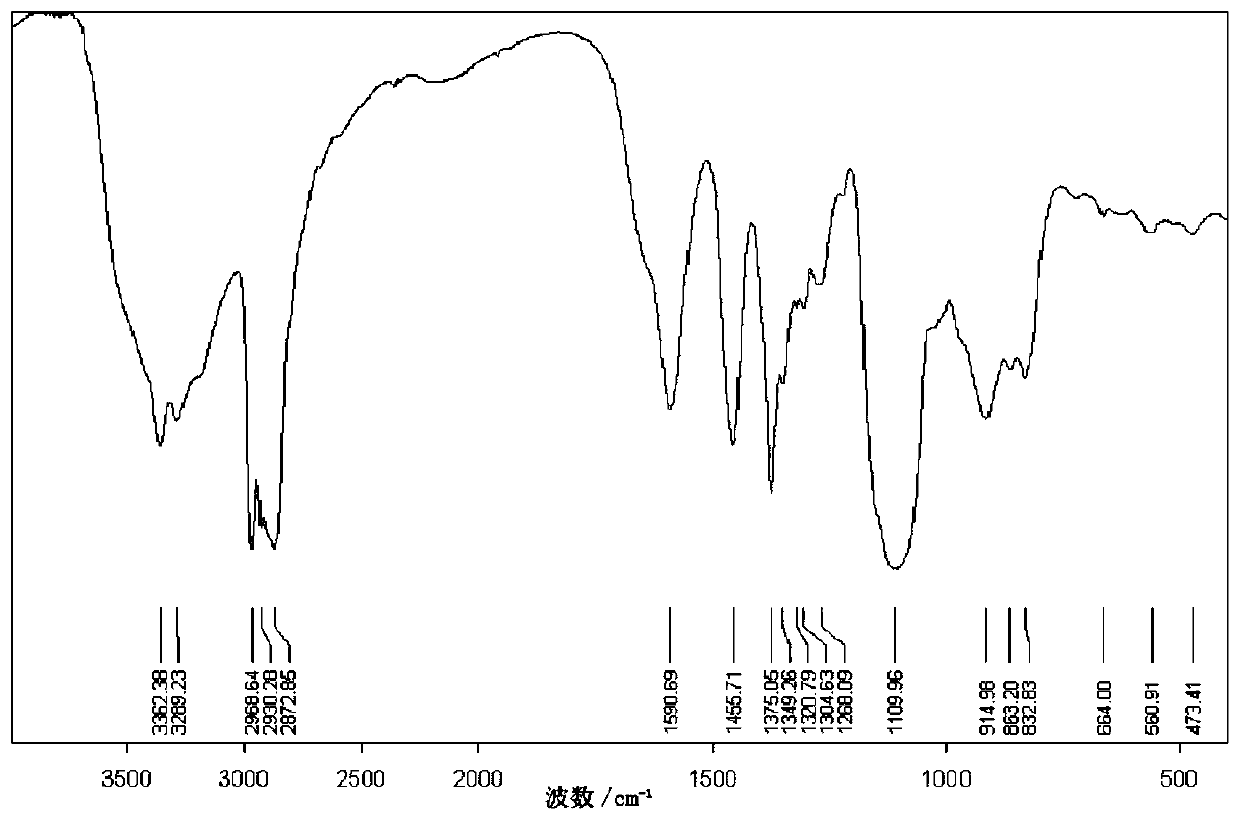

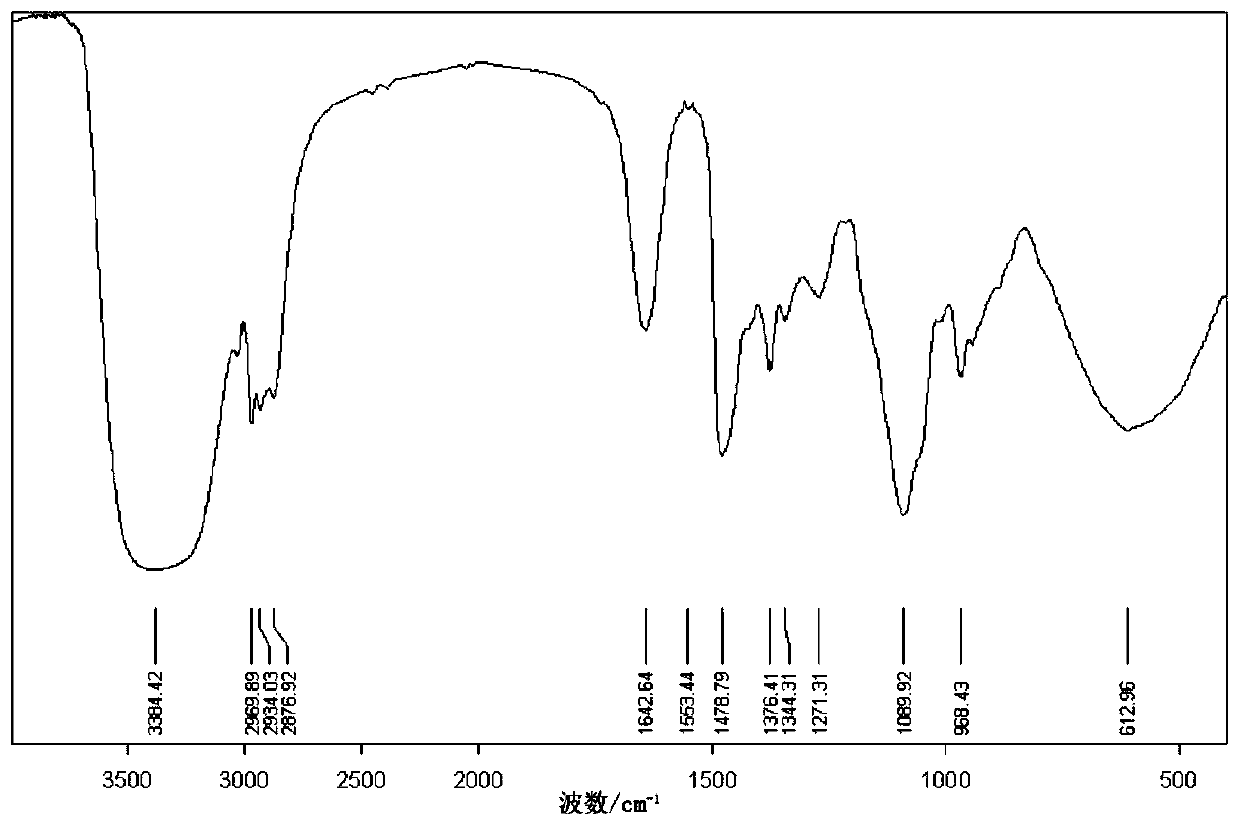

[0015] The infrared spectrum of polyetheramine D-230 and Y-564 is shown in figure 2 with image 3 . figure 2 Middle: at 3362cm -1 and 3289cm -1 The peak at is saddle-shaped, which is the symmetric and asymmetric stretching vibration peak of N—H in primary amine; 1590cm -1 is the in-plane bending vibration peak of N—H; 1109cm -1 The C-O-C stretching vibration peak. image 3 Middle: 3384cm -1 The stretching vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com