Method for using graphene/shell to prepare antibacterial paper

A graphene, antibacterial paper technology, applied in non-woody plant/crop pulp, cellulose treatment with microorganisms/enzymes, paper, etc., can solve the problem of insufficient pulping technology, low pulping yield, low kappa value, etc. problem, to achieve the effect of simple pulping process, high fiber yield and low kappa value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

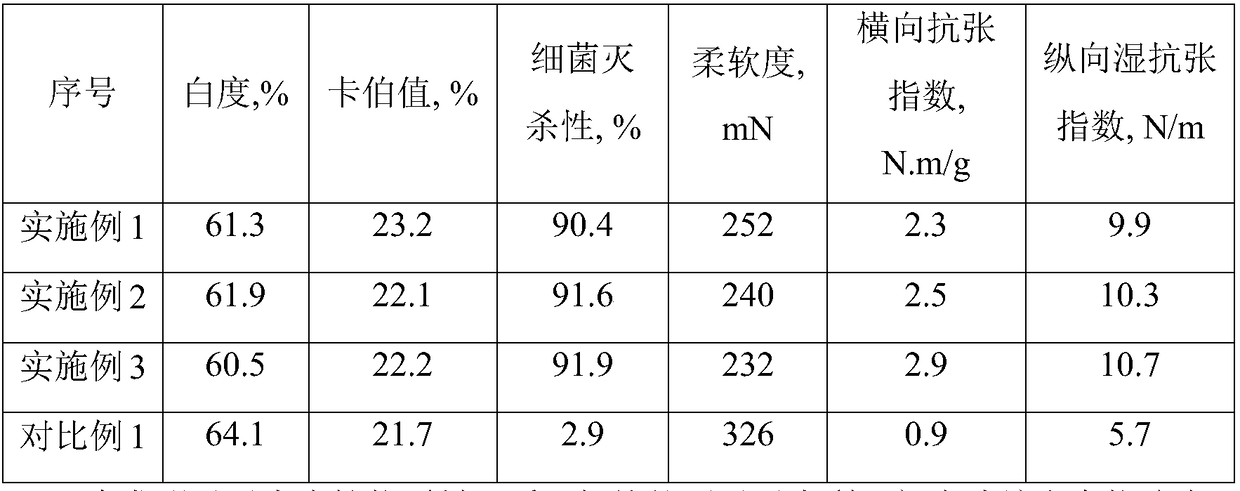

Examples

Embodiment 1

[0027] The method that utilizes graphene / husk to prepare antibacterial paper provided by the present embodiment comprises the following steps:

[0028] S1. Carry out deslagging treatment on the fruit shell, remove the silt and dust therein, dry until the water content is 20%, carry out the screw extrusion process on the above fruit shell, and set aside;

[0029] S2. the fruit shell of step S1 is placed in the ultrasonic reactor, add catalase, laccase and water, the consumption of catalase is 1.5 kilograms / ton material, and the consumption of laccase is 3 kilograms / ton material, water and The mass ratio of the fruit shell is 8:1, fully mixed, and fermented for 2 hours at a temperature of 70°C, and filtered after the fermentation to obtain filtrate and filtrate;

[0030] S3. add graphene dispersion liquid in the filtrate that step S2 obtains, after mixing uniformly, carry out decompression filtration 40min, dry 60min at 50 ℃, obtain the fruit shell fiber containing graphene; Fru...

Embodiment 2

[0036] The method that utilizes graphene / husk to prepare antibacterial paper provided by the present embodiment comprises the following steps:

[0037] S1. Carry out deslagging treatment to the fruit shell, remove the silt and dust therein, dry until the water content is 30%, carry out the screw extrusion process on the above fruit shell, and set aside;

[0038] S2. the fruit shell of step S1 is placed in the ultrasonic reaction kettle, add catalase, laccase and water, the consumption of catalase is 3 kilograms / ton material, and the consumption of laccase is 5 kilograms / ton material, water and The mass ratio of the fruit shell is 4:1, fully mixed, and fermented, the fermentation time is 4 hours, the temperature is 80°C, and the filtrate and the filtrate are obtained by filtering after the fermentation is completed;

[0039] S3. add graphene dispersion liquid in the filtrate that step S2 obtains, after mixing uniformly, carry out decompression filtration 60min, dry 120min at 80...

Embodiment 3

[0045] The method that utilizes graphene / husk to prepare antibacterial paper provided by the present embodiment comprises the following steps:

[0046] S1. Carry out deslagging treatment on the fruit shell, remove the silt and dust therein, dry until the water content is 25%, carry out the screw extrusion process on the above fruit shell, and set aside;

[0047] S2. the fruit shell of step S1 is placed in the ultrasonic reaction kettle, add catalase, laccase and water, the consumption of catalase is 2 kilograms / ton material, and the consumption of laccase is 4 kilograms / ton material, water and The mass ratio of the fruit shell is 5:1, fully mixed, and fermented, the fermentation time is 4 hours, the temperature is 75°C, and after the fermentation is completed, it is filtered to obtain the filtrate and the filtrate;

[0048] S3. add graphene dispersion liquid in the filtrate that step S2 obtains, after mixing uniformly, carry out decompression filtration 50min, dry 80min at 60 ℃,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com