Fabrication method of novel GaN-based LED

A new type of blue-light material technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of phosphor waste, complicated process, and high excitation temperature, and achieve the effects of reducing production costs, flexible luminous colors, and high device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

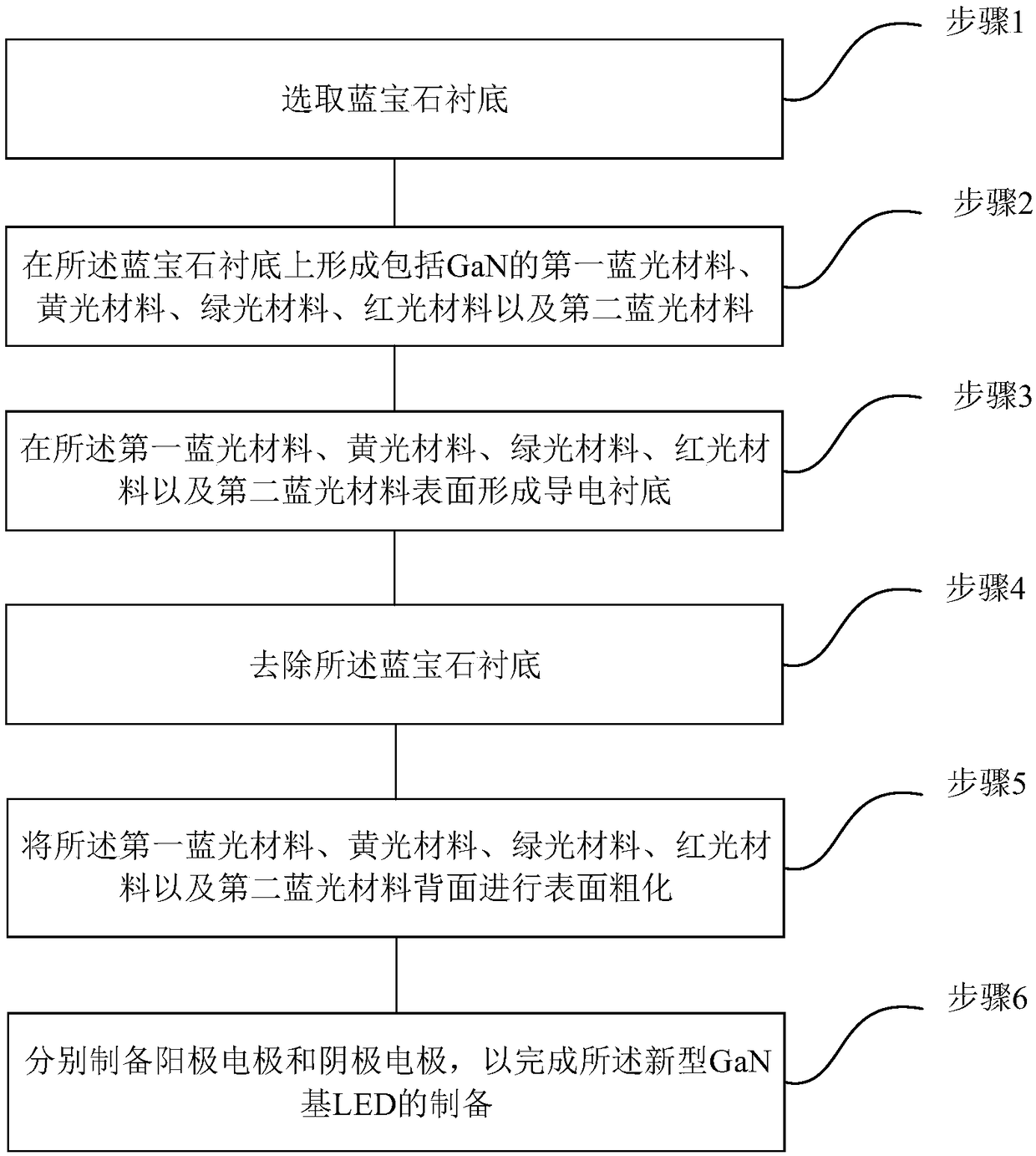

[0060] See figure 1 , figure 1 A flow chart of a novel GaN-based LED manufacturing method provided by an embodiment of the present invention. This preparation method comprises the steps:

[0061] Step 1, select the sapphire substrate;

[0062] Step 2, forming a first blue light material, a yellow light material, a green light material, a red light material and a second blue light material including GaN on the sapphire substrate;

[0063] Step 3, forming a conductive substrate on the surface of the first blue light material, yellow light material, green light material, red light material and second blue light material;

[0064] Step 4, removing the sapphire substrate;

[0065] Step 5, roughening the back surface of the first blue light material, yellow light material, green light material, red light material and second blue light material;

[0066] Step 6. Prepare the anode electrode and the cathode electrode respectively, so as to complete the preparation of the novel GaN...

Embodiment 2

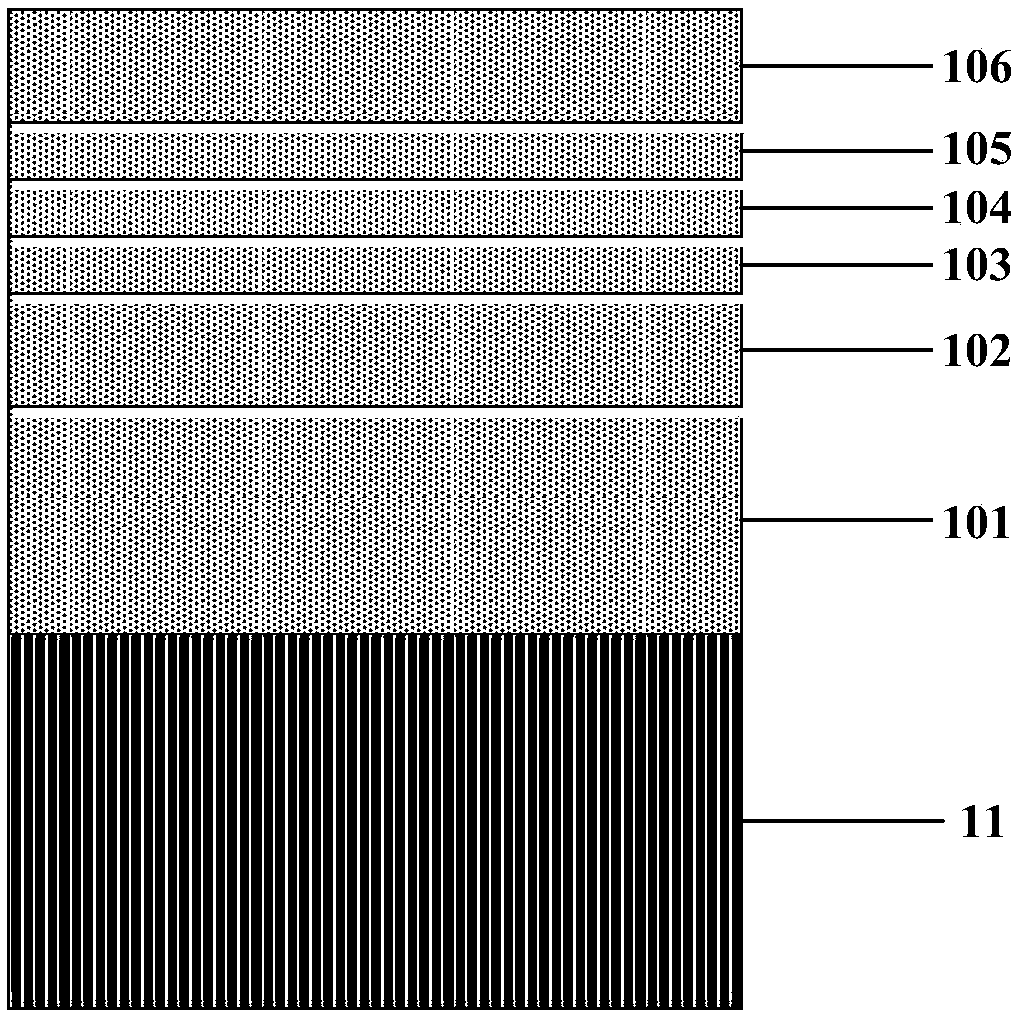

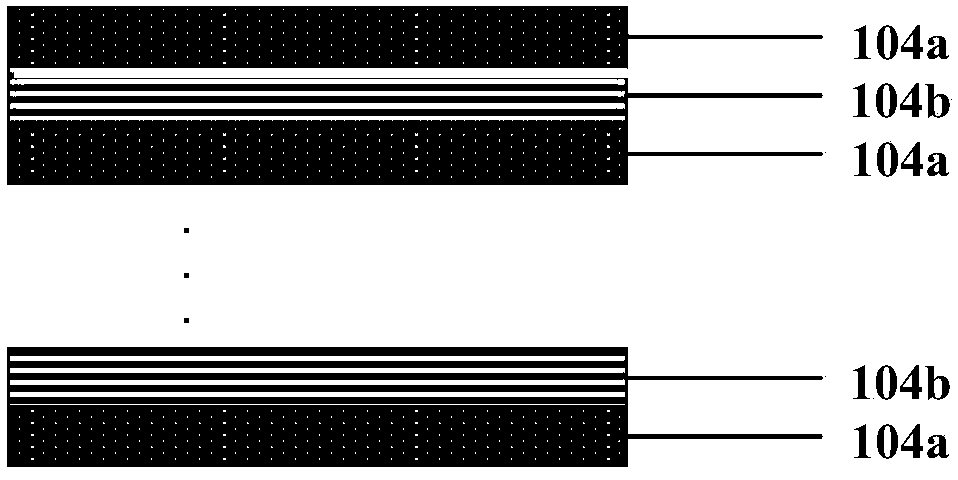

[0094] See Figure 2 to Figure 16 , figure 2 A schematic diagram of the growth of a blue light material provided by an embodiment of the present invention; image 3 A schematic diagram of the growth of a first active layer provided by an embodiment of the present invention; Figure 4 A schematic diagram of the preparation of a yellow light wick groove provided by the embodiment of the present invention; Figure 5 A schematic diagram of the growth of a yellow light material provided by the embodiment of the present invention; Image 6 A schematic diagram of the growth of a second active layer provided by an embodiment of the present invention; Figure 7 A schematic diagram of the preparation of a green light wick groove provided by the embodiment of the present invention; Figure 8 A schematic diagram of the growth of a green light material provided by an embodiment of the present invention; Figure 9 A schematic diagram of the growth of a third active layer provided by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com