Preparation method for porous NiO nano slice catalyst for catalyzing and decomposing N2O at low temperature

A nano-sheet, low-temperature catalysis technology, applied in physical/chemical process catalysts, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high conversion rate and high temperature, achieve high catalytic activity, preparation method Simple and convenient for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

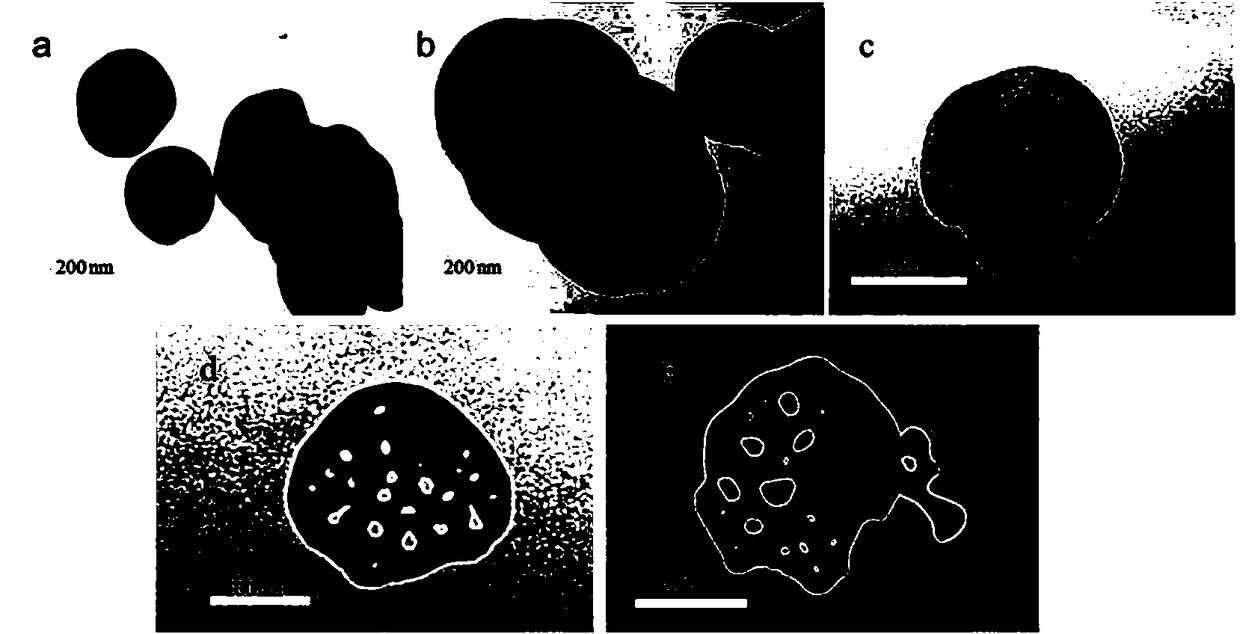

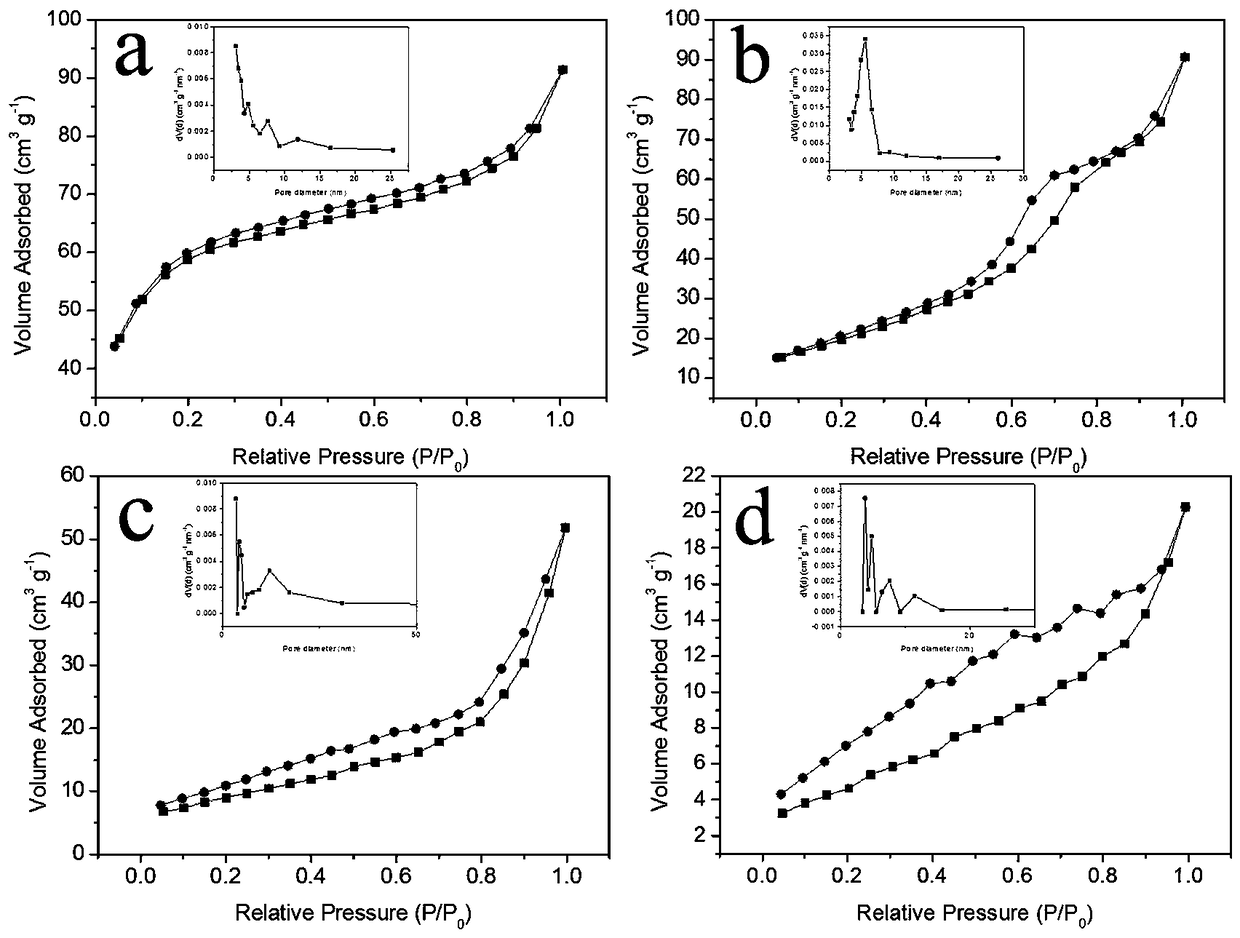

[0024] Weigh 1.18g NiCl 2 ·6H 2 O and 0.4g NaOH were completely dissolved in 10mL and 30mL deionized water respectively, and the obtained NaOH solution was added NiCl under stirring condition. 2 solution, transfer the mixed solution to a reaction kettle and seal it, place it in an electronic furnace and raise the temperature to 180°C for 10 hours. After the reaction is completed, cool it to room temperature, filter the green precipitate and wash it several times with deionized water and absolute ethanol , placed in an oven and dried at 60°C to obtain a precursor, as attached figure 1 As shown in a, the dried precipitate was annealed in a quartz tube furnace at 300 °C for 2 hours, and the heating rate was 5 °C min -1 , as attached figure 1 As shown in b, the porous NiO nanosheet catalyst.

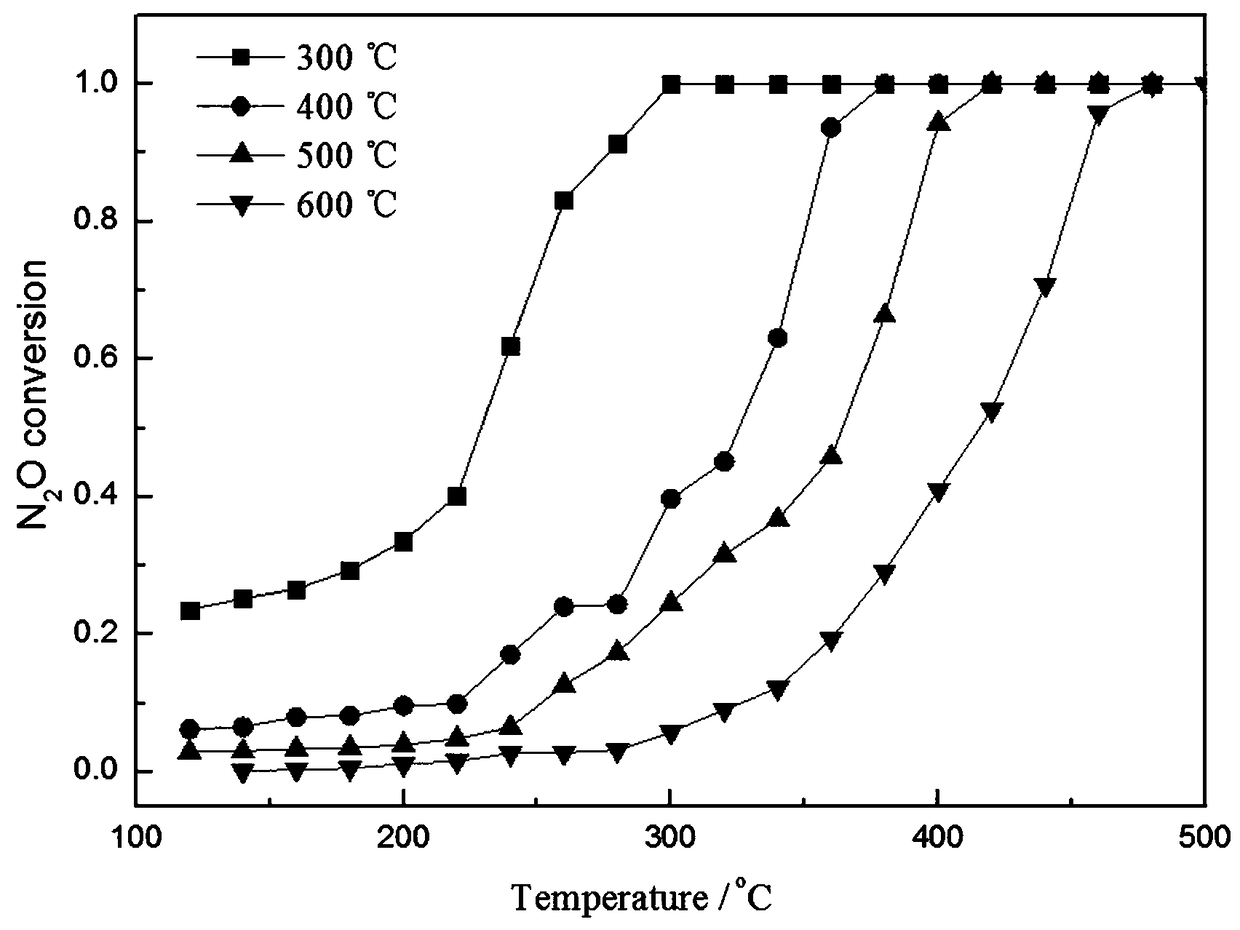

[0025] Take 300 mg of the above catalyst and put it into the 8 mm quartz reaction tube of the continuous flow micro-reaction device, and feed N 2 The mixed gas of O and Ar reacts, N 2 ...

Embodiment example 2

[0027] The annealing temperature in Example 1 was changed to 400°C.

[0028] Adopt embodiment 1 evaluation condition, under above-mentioned evaluation condition, obtain its specific surface area by attached table 1 and be 72m 2 g -1 , by attached image 3 It can be seen that when the catalytic temperature is 380°C, N 2 O conversion reaches 100%.

Embodiment 3

[0030] The annealing temperature in Example 1 was changed to 500°C.

[0031] Adopt embodiment 1 evaluation condition, under above-mentioned evaluation condition, obtain its specific surface area by attached table 1 and be 33m 2 g -1 , by attached image 3 It can be seen that when the catalytic temperature is 420°C, N 2 O conversion reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com