Potassium extraction processing technology of a kind of low-sulfur potassium mixed salt

A processing technology, potassium mixed salt technology, applied in the direction of alkali metal halide purification, etc., can solve the problems of low grade of potassium chloride products, low recovery rate, etc., to improve and reduce the K+ grade of tailings, improve product quality, and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

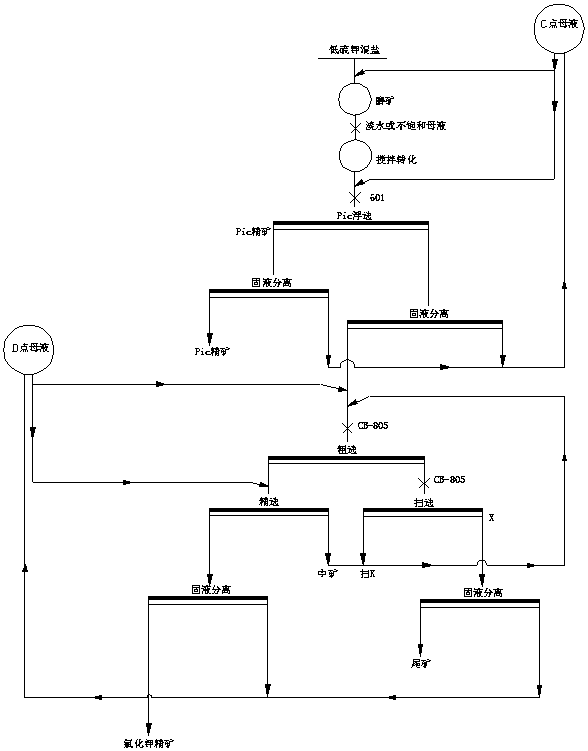

[0024] refer to figure 1 , a potassium-extracting processing technology of low-sulfur potassium mixed salt, comprising the following steps:

[0025] (1) A potassium mixed salt mine, the original ore composition is K + 11.88%, Na + 12.63%, Mg 2+ 4.690%, Cl - 33.41%, SO 4 2- 14.47%, other 22.92%;

[0026]Take by weighing above-mentioned potassium mixed salt ore 100.0 kg and C point (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (5) Potassium chloride, kaleinite, and epsomium salt in the metastable phase diagram of the five-yuan water-salt system) 80.0kg after mixing, enter the rod mill to grind to -100 mesh, add 25.0kg of fresh water, and stir Stir in the barrel for 120 minutes, and control the transformation temperature at 23-25°C to obtain the transformed ore pulp;

[0027] (2) Transfer the pulp obtained in step (1) to the flotation machine, add point C (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (5) Potassium chloride, magnesite, and epsom salt in the metastabl...

Embodiment 2

[0033] A kind of processing technology for extracting potassium of low-sulfur potassium mixed salt, comprising the following steps:

[0034] (1) A potassium mixed salt mine, the raw ore composition is K + 11.88%, Na + 12.63%, Mg 2+ 4.690%, Cl - 33.41%, SO 4 2- 14.47%, other 22.92%;

[0035] Take by weighing 100.0 kg of the above-mentioned potassium mixed salt ore and the flotation filtrate (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (0) Potassium chloride, kaleinite, and epsomium salt in the metastable phase diagram of the five-element water-salt system) After mixing 54.0kg, enter the rod mill to grind to -100 mesh, add 35.0kg of fresh water, and stir Stir in the barrel for 100 minutes, and control the transformation temperature at 24-26°C to obtain the transformed ore pulp;

[0036] (2) Transfer the pulp obtained in step (1) to the flotation machine, add point C (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (0) The mother liquor in the metastable phase diagram ...

Embodiment 3

[0042] A kind of processing technology for extracting potassium of low-sulfur potassium mixed salt, comprising the following steps:

[0043] (1) A potassium mixed salt mine, the raw ore composition is K + 10.24%, Na + 20.46%, Mg 2+ 2.92%, Cl - 40.85%, SO 4 2- 11.63%, other 13.90%;

[0044] Take by weighing 100.0 kg of the above-mentioned potassium mixed salt ore and the flotation filtrate (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (0) Potassium chloride, kaleinite, and epsomium salt in the metastable phase diagram of the five-yuan water-salt system) 66.6kg after mixing, enter the rod mill to grind to -100 mesh, add 15.0kg of fresh water, and stir Stir in the barrel for 80 minutes, and control the conversion temperature at 23-25°C to obtain the converted pulp;

[0045] (2) Transfer the pulp obtained in step (1) to the flotation machine, add point C (Na + 、K + , Mg 2+ / / Cl - , SO 4 2- —H 2 (5) the mother liquor in the metastable phase diagram of the five-elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com