Standard solution for detecting content of trace elements in quartz sand and preparation method of standard solution

A medium and trace element, standard solution technology, applied in instruments, thermal excitation analysis, analysis materials, etc., can solve the problems affecting the accuracy of analysis results, large matrix interference, high price, etc., to eliminate matrix interference, difficult to concentration change, Good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

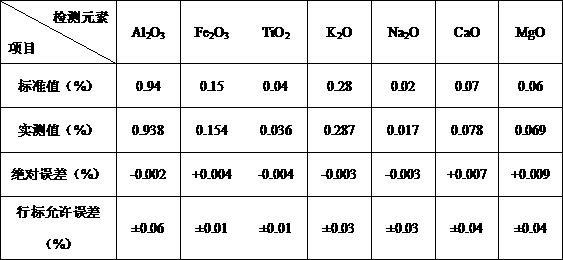

[0046] Embodiment one, Al in the siliceous sandstone standard sample of known composition 2 o 3 , Fe 2 o 3 、TiO 2 、K 2 O, Na 2 Detection of O, CaO and MgO content:

[0047] 1. Accurately weigh 0.2g of a siliceous sandstone standard sample that has been dried at 100°C for 2 hours in a platinum dish, moisten it with a small amount of water, add 1mL of perchloric acid and 10mL of hydrofluoric acid, heat and dissolve on a low-temperature electric furnace, and evaporate to Dry until the white smoke is exhausted, cool, add 10mL nitric acid and appropriate amount of water, heat to dissolve, transfer to a 100mL volumetric flask after cooling, dilute with water to the marked line, and shake well. Use the same procedure to make a reagent blank.

[0048] 2. Ignite, preheat the ICP instrument, set the best instrument conditions, according to the analysis control program, inhale 5% nitric acid solution standard blank solution and the multi-element standard series solution prepared b...

Embodiment 2

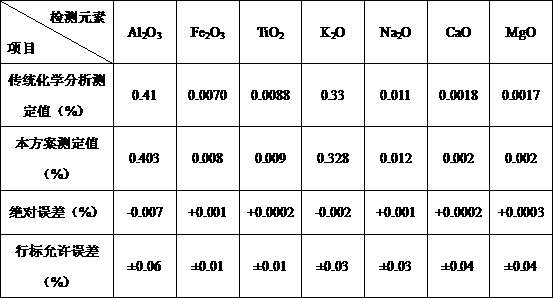

[0052] Embodiment two, in the quartz sand of Fengyang, Anhui Province, Al 2 o 3 , Fe 2 o 3 、TiO 2 、K 2 O, Na 2 Detection of O, CaO and MgO content:

[0053] 1. Accurately weigh 0.5000g of the quartz sand sample from Fengyang, the place of origin, which has been dried at 105°C-110°C for 2 hours, put it in a platinum dish, moisten it with a small amount of water, add 1mL perchloric acid and 10mL hydrofluoric acid on a low-temperature electric furnace Heat to dissolve, evaporate to dryness until the white smoke exhausts, cool, add 10mL nitric acid (1+1) and appropriate amount of water, heat to dissolve, transfer to a 100mL volumetric flask after cooling, dilute with water to the marked line, and shake well. Use the same procedure to make a reagent blank.

[0054] 2. Ignite, preheat the ICP instrument, set the best instrument conditions, according to the analysis control program, inhale 5% nitric acid solution standard blank solution and the multi-element standard series so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com