A two-dimensional material source follower with gas sensing function

A two-dimensional material and gas sensing technology, applied in the direction of material resistance, etc., can solve the problems of poor signal optimization, sensor signal influence, parasitic effects, etc., and achieve good energy band width and high carrier transfer rate , the effect of a good on-off ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

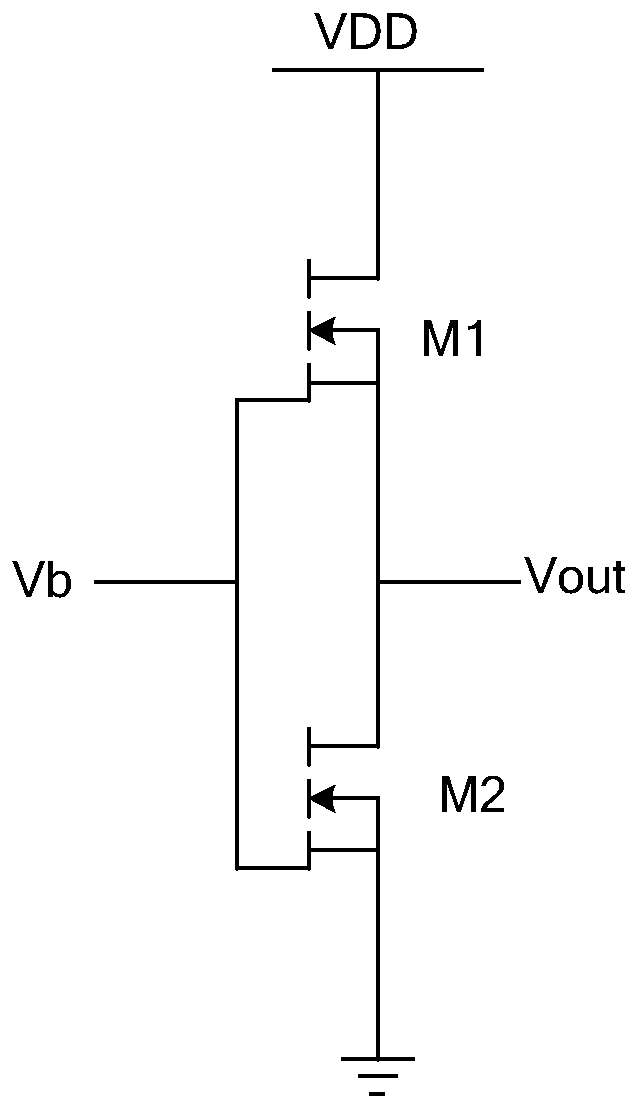

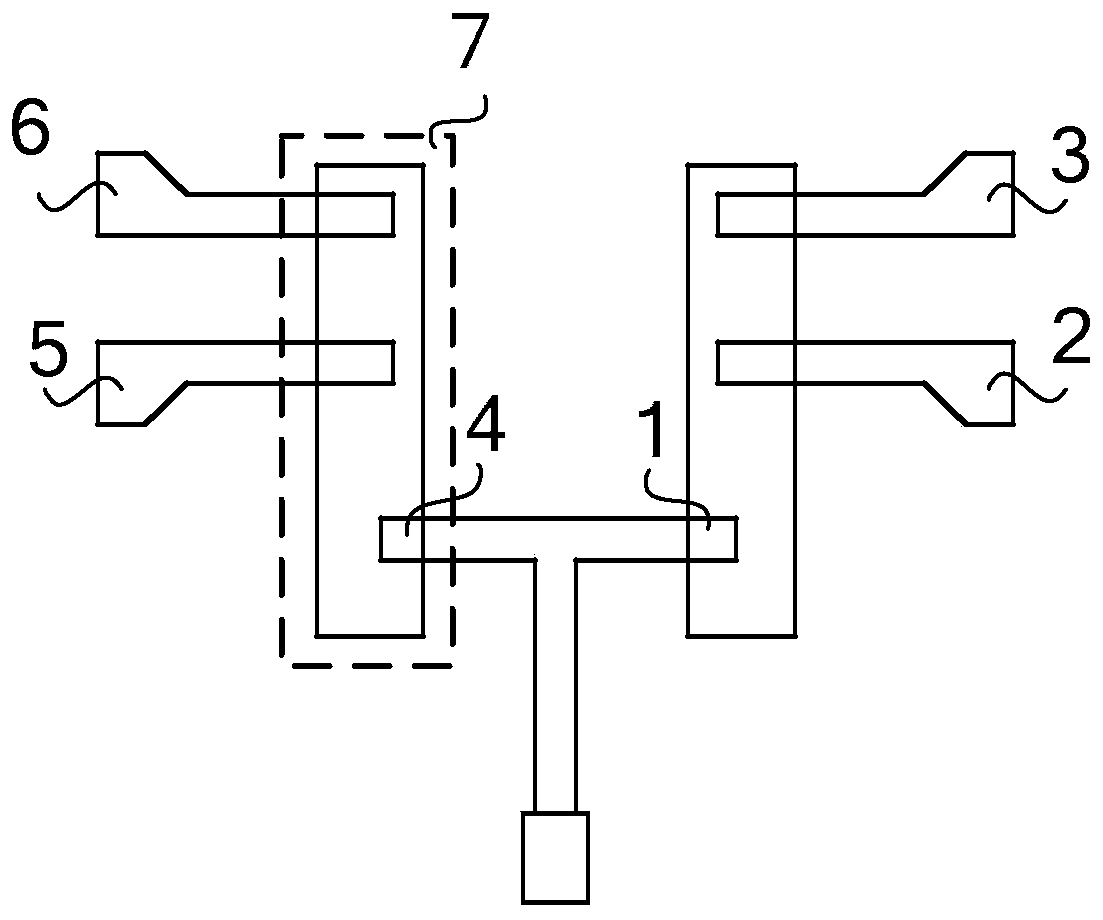

[0020] In order to realize the integrated system structure of sensor and circuit, the present invention adopts such as figure 1 The circuit structure of the source follower shown, figure 2 Shown is the layout structure diagram of the follower.

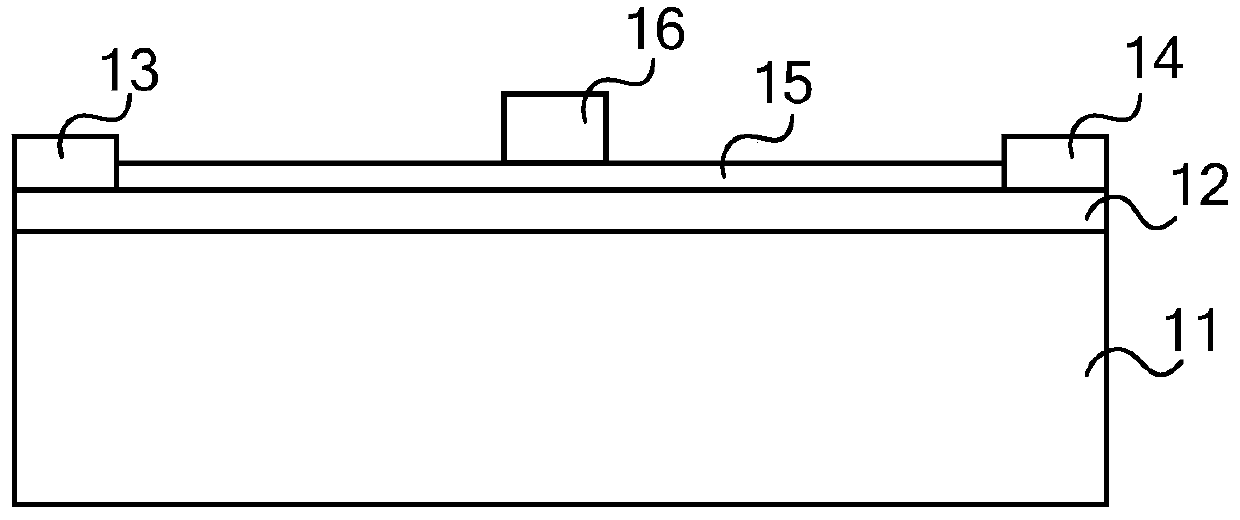

[0021] like figure 1 and 2 , the circuit of the source follower consists of two two-dimensional materials WS 2 fabricated transistors. The first NMOS transistor M1 is used as a gas sensor; the drain 1 of the first NMOS transistor M1 is connected to the power supply voltage VDD, and the gate 2 of the first NMOS transistor M1 is connected to the reference voltage Vb, so that the first NMOS transistor M1 works in the saturation region, and the first NMOS transistor M1 works in the saturation region. The source 3 of an NMOS transistor M1 is connected to the drain 4 of the second NMOS transis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com