Preparation method for Fe Mn alloy nanometer thin films with high exchange biasing effect

A technology of alloy nanometer and bias effect, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of controlling film size and thickness, complex alloy film process, unstable reaction conditions, voltage and current, etc. problems, to achieve the effect of controlling the grain size, large exchange bias effect, and reducing the interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

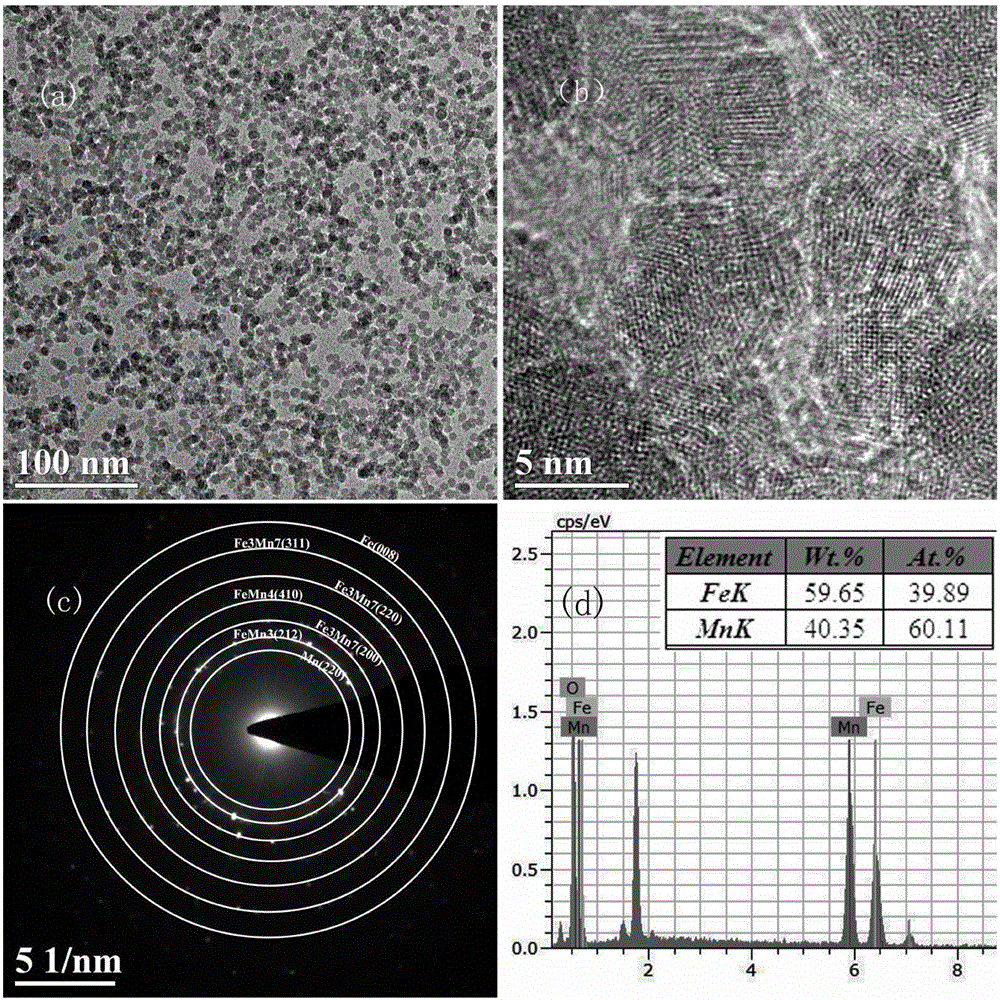

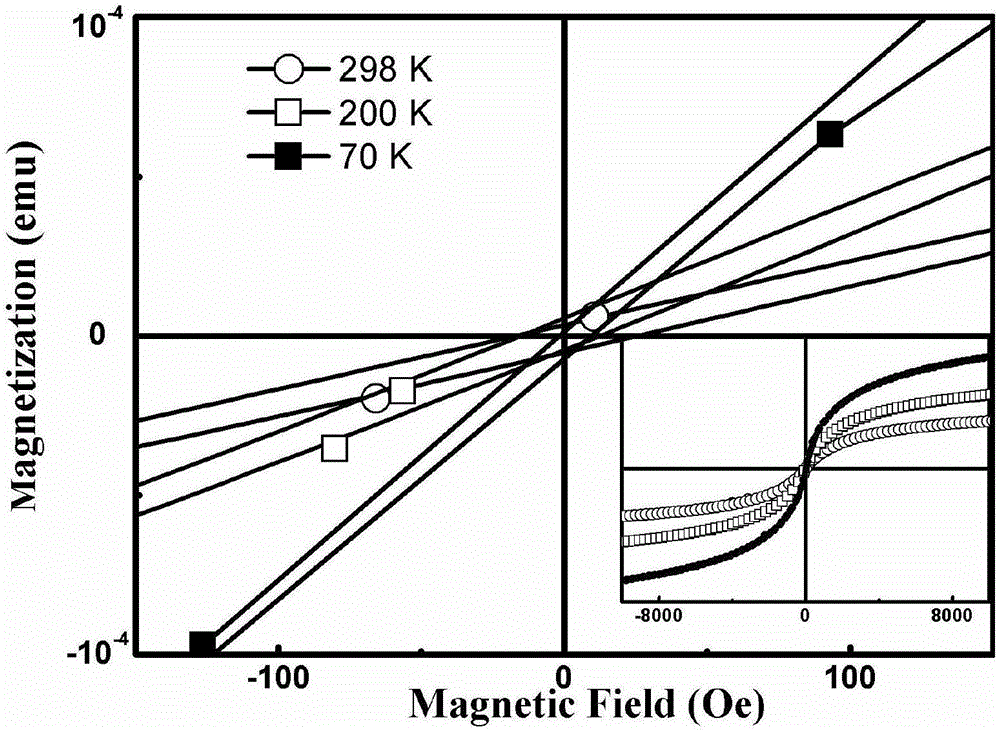

[0039] The preparation of FeMn alloy nano-films under annealing conditions, test the hysteresis loops of FeMn alloy nano-films at temperatures of 70K, 100K, 150K, 200K, 250K, 298K.

[0040] The following raw materials (with a purity of over 99.999%) are used to prepare nano-assembled FeMn alloy films using an improved pre-sputtering half-hour target method;

[0041] The following is the specific method for preparing FeMn alloy nano film with strong exchange bias effect

[0042] 1.1): A FeMn alloy target with a purity of 99.999%, a thickness of 2mm and a diameter of 50mm is used as a sputtering target, an Ar with a purity of 99.999% is used as a sputtering gas, and a thickness of 500μm, 10mm*10mm (100) silicon The sheet serves as the substrate.

[0043] 1.2): Soak the dust-free paper in step 1 in the absolute ethanol in step 1 for 10 seconds, wipe the impurities in the cluster condensation cavity with the dust-free paper soaked in absolute ethanol, and wipe clean the impurities in the ...

Embodiment 2

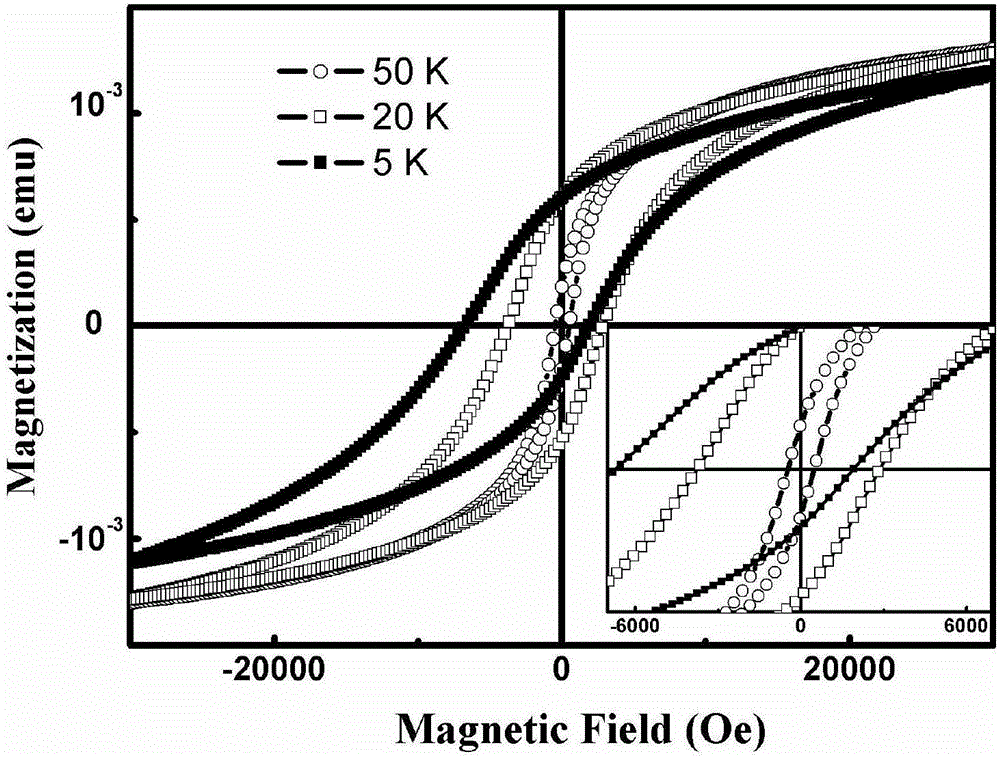

[0052] Prepare FeMn alloy nano-films with strong exchange bias effect under annealing conditions, and test the hysteresis loops of FeMn alloy nano-films at temperatures of 5K, 15K, 20K, 25K, 30K, 40K, and 50K.

[0053] The following raw materials (with a purity of more than 99.999%) were used to prepare nano-assembled FeMn alloy films using an improved pre-sputtering half-hour target method; considering that FeMn alloy nano-films are easy to oxidize under high temperature conditions, 400 in an argon atmosphere In-situ annealing at ℃ for 15min to prevent the composition of FeMn alloy nano film from changing.

[0054] The specific method is:

[0055] 2.1): A FeMn alloy target with a purity of 99.999%, a thickness of 2mm and a diameter of 50mm is used as a sputtering target, an Ar with a purity of 99.999% is used as a sputtering gas, and a (100) silicon with a thickness of 500μm and 10mm*10mm The sheet serves as the substrate.

[0056] 2.2): Soak the dust-free paper in step 1 in the abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com