Alignment film, preparation method thereof, display substrate and display device

An alignment film and base material technology, which is applied in the fields of display devices, its preparation, display substrates, and alignment films, can solve problems such as bright spots and gypsophila dots, alignment film scratches, and poor panel images, so as to reduce bright spots and the effect on the incidence of Gypsophila punctate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

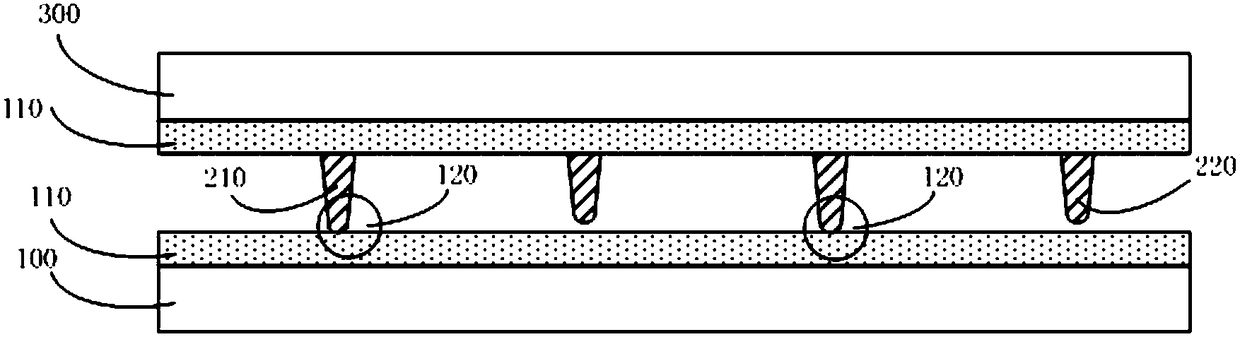

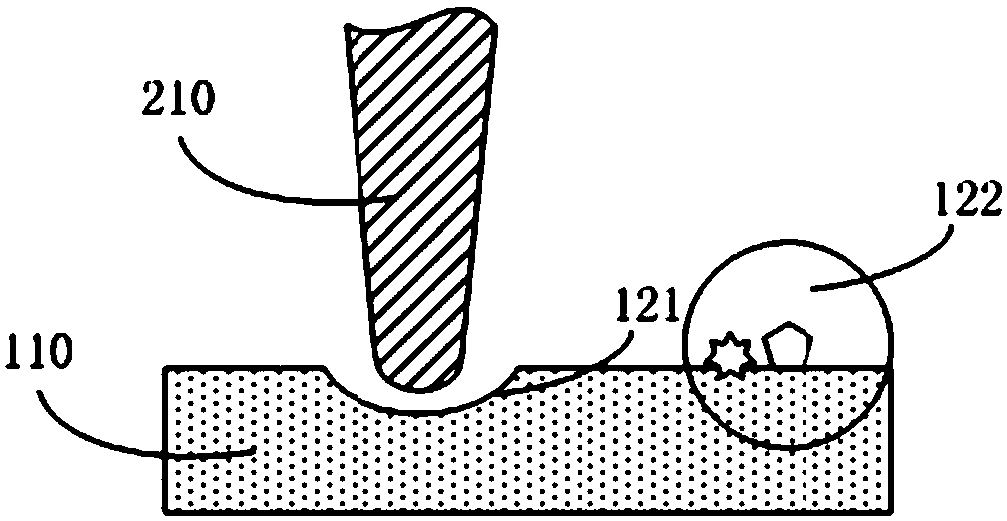

[0048] The embodiment of the present invention also discloses a method for preparing an alignment film, which includes the following steps:

[0049] The microcapsules and the catalyst are mixed into the solution containing the substrate intermediate, and after curing, an alignment film is obtained;

[0050] The microcapsule contains a first monomer, and the catalyst can catalyze the polymerization reaction of the first monomer.

[0051] In an embodiment of the present invention, the microcapsules and the catalyst are added to the solution containing the substrate intermediate. For the selection of the microcapsules and catalyst, refer to the above-mentioned technical solutions, and details are not repeated here.

[0052] The substrate intermediate refers to an intermediate produced during the preparation of the substrate, and the substrate is obtained after the intermediate is cured. For example, the substrate is polyimide, and the substrate intermediate is polyamic acid.

...

Embodiment 1

[0076] Divinylbenzene is mixed with an appropriate amount of deionized water, and the mixture is uniformly dispersed under high-speed dispersion conditions, and divinylbenzene exists in the mixed liquid in the state of uniform droplets;

[0077] In the mixed liquid, add BPO (free radical initiator), formaldehyde solution (mass concentration of formaldehyde is 37% to 40%) and urea, formaldehyde and urea are polymerized with divinylbenzene droplets as the core to form urea-formaldehyde resin Emulsion of microcapsules wrapped in divinylbenzene;

[0078] Use urea-formaldehyde resin-wrapped divinylbenzene microcapsule emulsion as the polymerization seed, add dibasic anhydride, diamine and silane coupling agent to dissolve in organic solvent, carry out polymerization reaction, heat to 50-80°C, and continue the reaction for 2- After 4 hours, polyimide was wrapped in the outer layer of phenolic resin to form a microcapsule emulsion with double-wall structure;

[0079] The microcapsul...

Embodiment 2~4

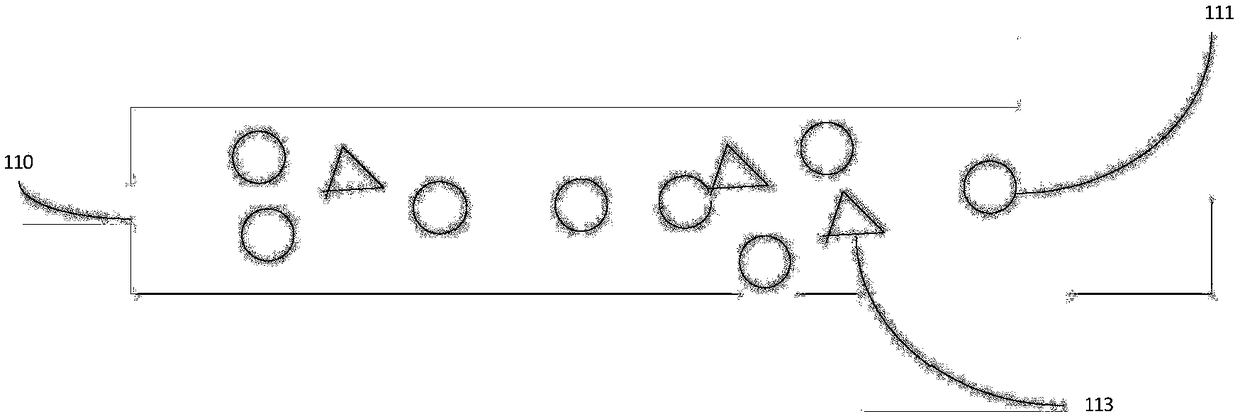

[0087] With the raw materials described in Table 2, the microcapsules were prepared. The microcapsules and the catalyst are doped in the polyamido acid solution, and coated on the substrate by a spin-coating coating process, with a thickness of The curing process is divided into pre-curing and main curing. The pre-curing temperature is 100-180°C, the pre-curing time is 50s-200s, the main curing temperature is 200-280°C, and the main curing time is 500-2000s. After curing, polyimide is obtained. The alignment film of the substrate.

[0088] In the alignment film, the mass of the microcapsule accounts for 5wt% of the mass of the polyimide substrate, the mass of the catalyst accounts for 0.3wt% of the mass of the polyimide substrate, and the alignment film.

[0089] Table 2

[0090]

[0091] A scratch test was performed on the alignment films prepared in Examples 2-4, and no obvious debris was generated.

[0092] The alignment films prepared in Examples 2-4 were used to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com