Baking-free preparation method of compounding food additive lactic acid powder through extruding and mixing of twin screw extruder

A twin-screw extrusion and food additive technology, which is applied in the field of food additives to ensure uniformity, quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, further description will be given below in conjunction with specific examples.

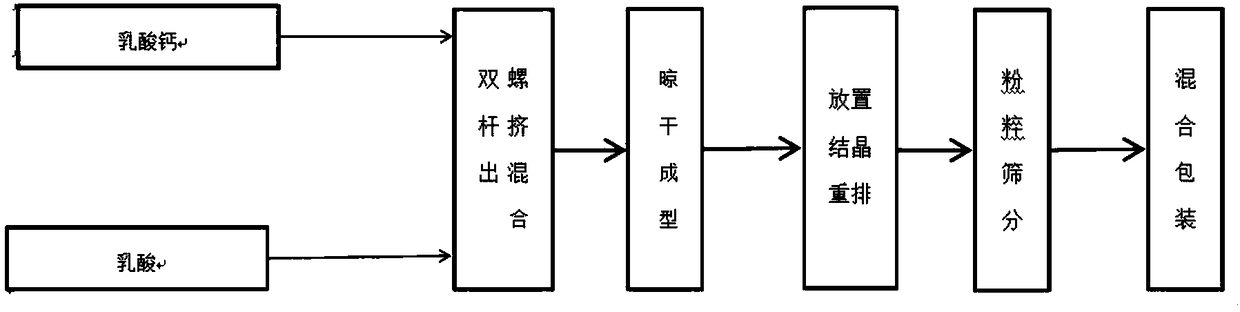

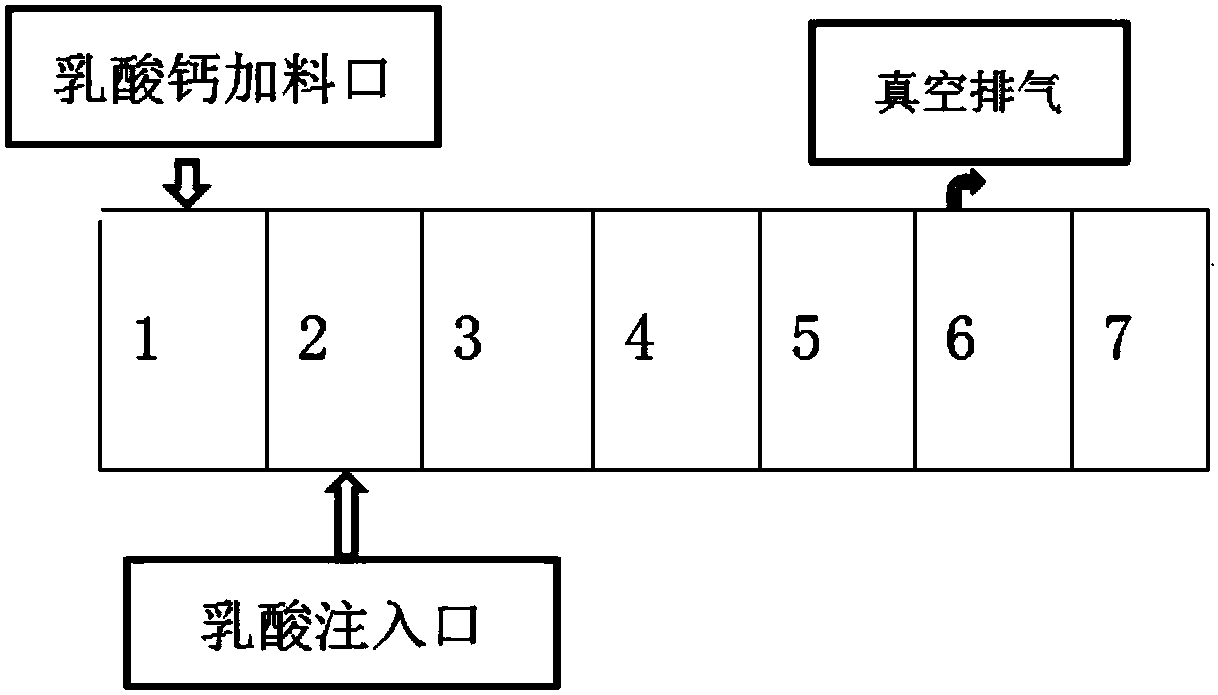

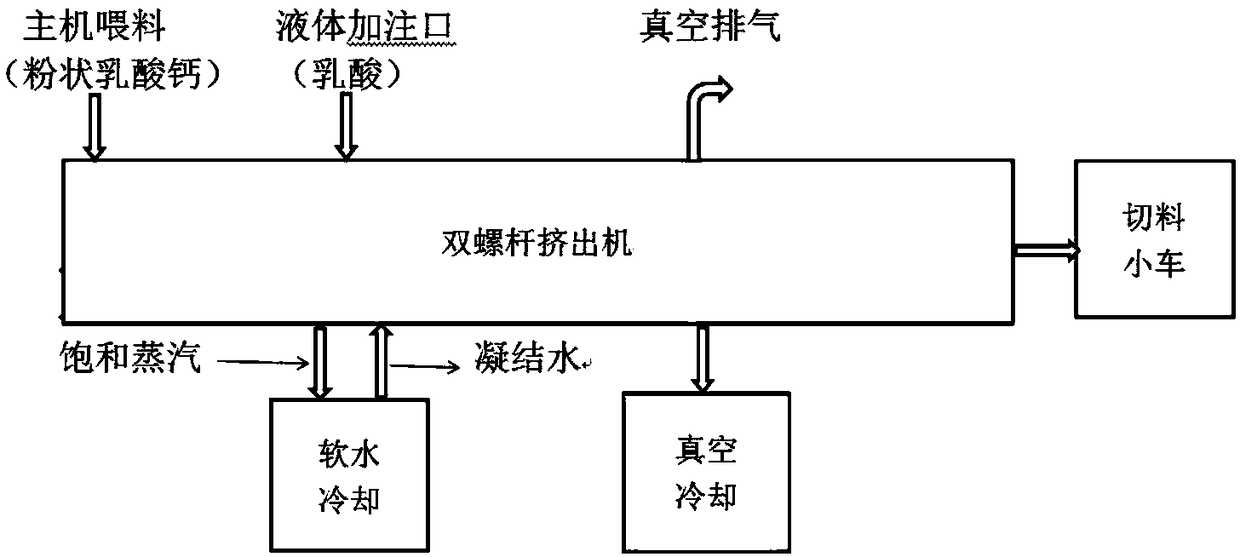

[0029] Process flow of the present invention such as figure 1 As shown, calcium lactate and lactic acid enter the twin-screw extruder from different feeding ports, and are conveyed forward under the mixing and extrusion of the screws. After discharging the crystallization, crush and sieve, and then add anti-caking agent. The cylinder and screw of the twin-screw extruder used in the present invention are made of 316L stainless steel or 2205 duplex stainless steel. The heating or cooling of the cylinder of the twin-screw extruder is indirect, the cooling medium is distilled water or industrial soft water, and the heating medium is suitable Saturated water vapor at pressure. The twin-screw extruder used is a seven-section barrel combined structure, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com