ZnFe2O4/TiO2 fruit and vegetable pesticide residue remover and preparation method thereof

A znfe2o4, scavenger technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of exceeding the self-purification capacity of water bodies, secondary pollution, pesticide entry, etc. problems, to achieve the effect of safe and environmentally friendly preparation process, safe production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

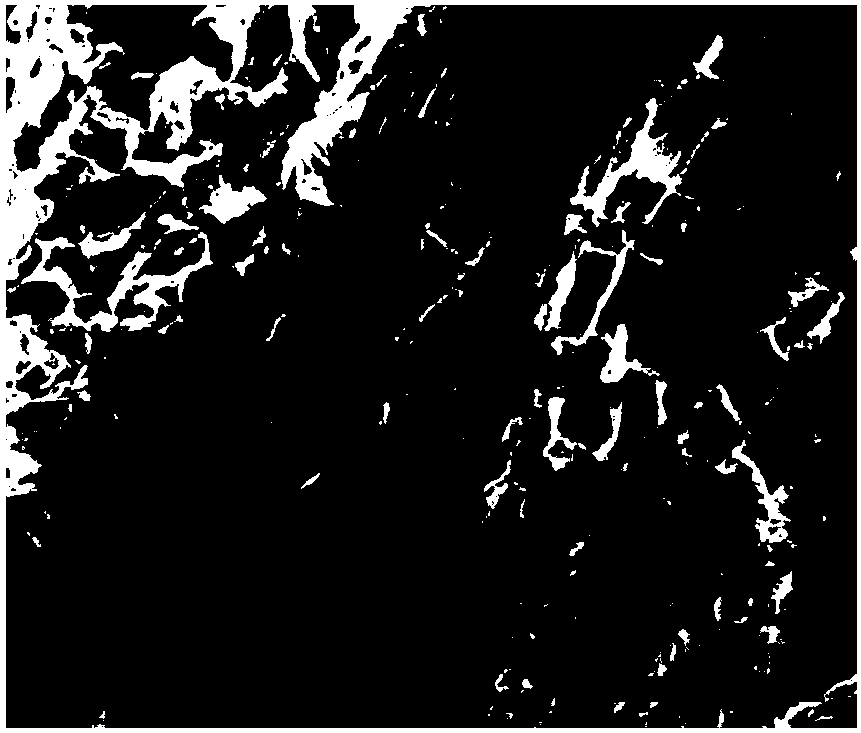

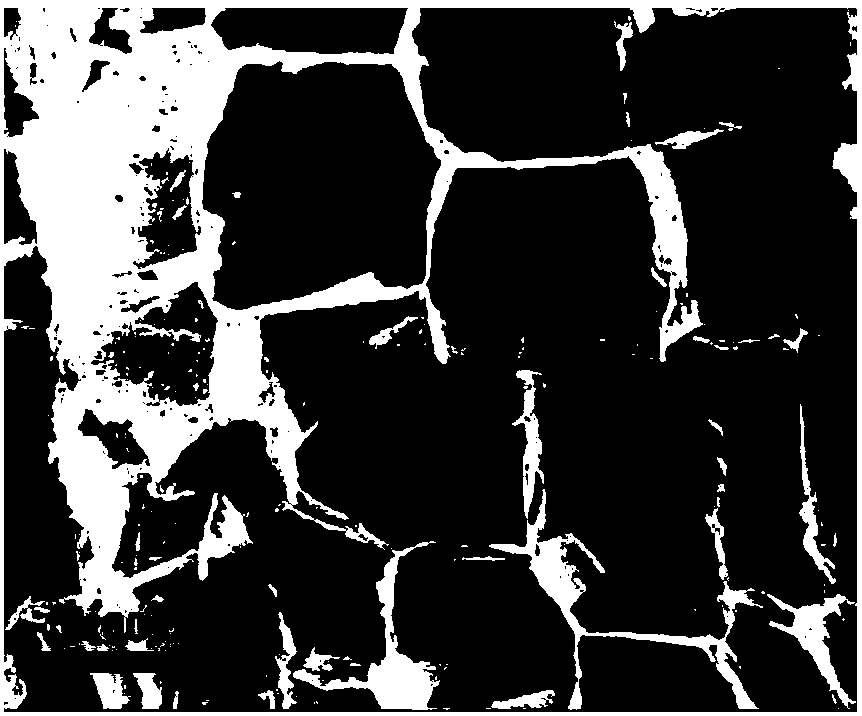

Image

Examples

Embodiment 1

[0026] Using corn stalks as a biological template, dry the corn stalks in an oven at 90 degrees Celsius for 10 hours; impregnate 10-20 parts of tetrabutyl titanate and 30-40 parts of absolute ethanol with 45-55 parts of corn stalks for two time, 24 hours each time; dry the impregnated corn stalks in an oven at 90 degrees Celsius for 10 hours, and roast the dried corn stalks in a roaster at 400-450 degrees Celsius for 10 hours to obtain the graded corn stalks as biological templates. Porous TiO2. Fully mix 50 parts of hierarchical porous TiO2 prepared with corn stalks as a biological template, 3 parts of Zn(NO3)2, 6 parts of FeCl2 and 41 parts of water, and make the mixing system uniform and stable under the action of ultrasound, using a stainless steel reactor as the reaction device , using a constant temperature oven as a heat source, put the stainless steel reaction kettle with reactants in a constant temperature oven, adjust the temperature of the constant temperature oven ...

Embodiment 2

[0029] Using corn stalks as a biological template, dry the corn stalks in an oven at 90 degrees Celsius for 10 hours; impregnate 20-40 parts of tetrabutyl titanate and 20-30 parts of absolute ethanol with 40-50 parts of corn stalks for two time, 24 hours each time; dry the impregnated corn stalks in an oven at 90 degrees Celsius for 10 hours, and roast the dried corn stalks in a roaster at 400-450 degrees Celsius for 10 hours to obtain the graded corn stalks as biological templates. Porous TiO2. Fully mix 50 parts of hierarchical porous TiO2 prepared with corn stalks as a biological template, 5 parts of Zn(NO3)2, 10 parts of FeCl2 and 35 parts of water, and make the mixing system uniform and stable under the action of ultrasound, using a stainless steel reactor as a reaction device , using a constant temperature oven as a heat source, put the stainless steel reaction kettle with reactants in a constant temperature oven, adjust the temperature of the constant temperature oven a...

Embodiment 3

[0032] Using sorghum straw as a biological template, dry the sorghum straw in an oven at 90 degrees Celsius for 10 hours; impregnate 10-20 parts of tetrabutyl titanate and 30-40 parts of absolute ethanol with 45-55 parts of sorghum straw for two time, 24 hours each time; dry the impregnated corn stalks in an oven at 90 degrees Celsius for 10 hours, and roast the dried corn stalks in a roasting furnace at 400-450 degrees Celsius for 10 hours to obtain the classification of sorghum stalks as biological templates Porous TiO2. Fully mix 50 parts of hierarchical porous TiO2 prepared with sorghum stalks as a biological template, 3 parts of Zn(NO3)2, 6 parts of FeCl2 and 41 parts of water, and make the mixing system uniform and stable under the action of ultrasound, using a stainless steel reactor as a reaction device , using a constant temperature oven as a heat source, put the stainless steel reaction kettle with reactants in a constant temperature oven, adjust the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com