Preparation method of gold nano-octahedrons

A technology of octahedron and gold nano, which is applied in the field of preparation of gold nano octahedron, can solve problems such as poor size uniformity of gold nano octahedron, complicated preparation process, and influence on product purity, and achieve good monodispersity, reduce error, The effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of gold nanometer octahedron, adopt cationic surfactant polydiallyl dimethyl ammonium chloride (PDDA) as protective agent and shape control agent, in pentanediol (PD ) is the solvent and reducing agent in the system, the chloroauric acid (HAuCl 4 ) in the next step of reductive synthesis at high temperature.

[0028] Polydiallyldimethylammonium chloride (PDDA, Mw=200000~300000, 20wt%), pentanediol (PD) and chloroauric acid (HAuCl) used in the present invention 4 ) are directly purchased from the market without any purification treatment before use.

[0029] According to the content of the present invention, a solution of chloroauric acid in pentanediol (PD) with a molar concentration of 20 mM is prepared for use.

Embodiment 1

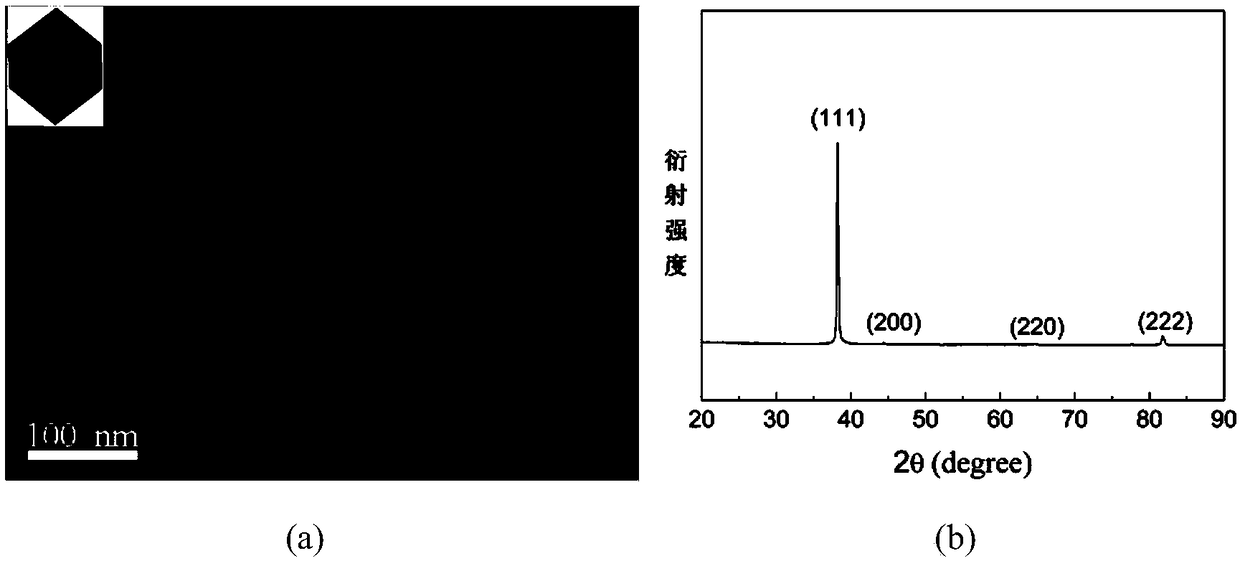

[0032] Under stirring conditions, 1 mL of chloroauric acid (HAuCl 4 ) of pentanediol (PD) solution and 0.8mL of polydiallyldimethylammonium chloride (PDDA) were added to the round bottom flask filled with 30mL of pentanediol (PD), in which chloroauric acid ( HAuCl 4 ) to polydiallyldimethylammonium chloride (PDDA) in a molar ratio of 1:50; after mixing and stirring evenly, the reaction solution is slightly yellow, and then reflux reaction at 220°C for 30 minutes, naturally cooled to room temperature to obtain a brown solution; the resulting solution was centrifuged at a speed of 15,000 rpm for 30 minutes with a high-speed centrifuge, and the upper layer of the colorless solution in the centrifuge tube was removed to obtain a brownish-yellow precipitated product, which is the product gold nanometer Octahedral granular material. The scanning electron microscope picture of the gold nano-octahedron prepared in this embodiment is as follows figure 1 As shown in (a), the results ...

Embodiment 2

[0034] Under stirring conditions, 1 mL of chloroauric acid (HAuCl 4 ) of pentanediol (PD) solution and 0.8mL of polydiallyldimethylammonium chloride (PDDA) were added to the round bottom flask filled with 30mL of pentanediol (PD), in which chloroauric acid ( HAuCl 4 ) to polydiallyldimethylammonium chloride (PDDA) in a molar ratio of 1:50; after being mixed and stirred evenly, the reaction solution is slightly yellow, and then refluxed at 200°C for 30 minutes, naturally cooled to room temperature to obtain a brown solution; the resulting solution was centrifuged at a speed of 15,000 rpm for 30 minutes with a high-speed centrifuge, and the upper layer of the colorless solution in the centrifuge tube was removed to obtain a brownish-yellow precipitated product, which is the product gold nanometer Octahedral granular material. The scanning electron microscope picture of the gold nano-octahedron prepared in this embodiment is as follows figure 2As shown, the results show that:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com