A kind of vacuum brazing method of molybdenum alloy and graphite

A brazing method and molybdenum alloy technology, applied in the field of connection of heterogeneous materials, can solve the problems of increasing wettability, cohesiveness, unsuitability for mass production, and low production efficiency, so as to improve wettability and be suitable for large batches The effect of improving production and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

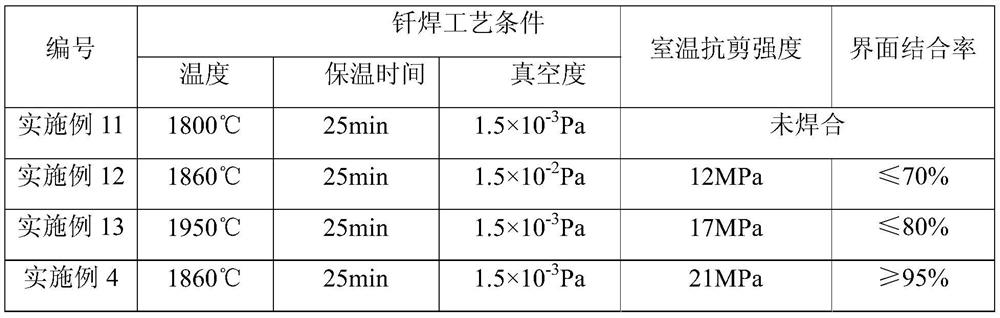

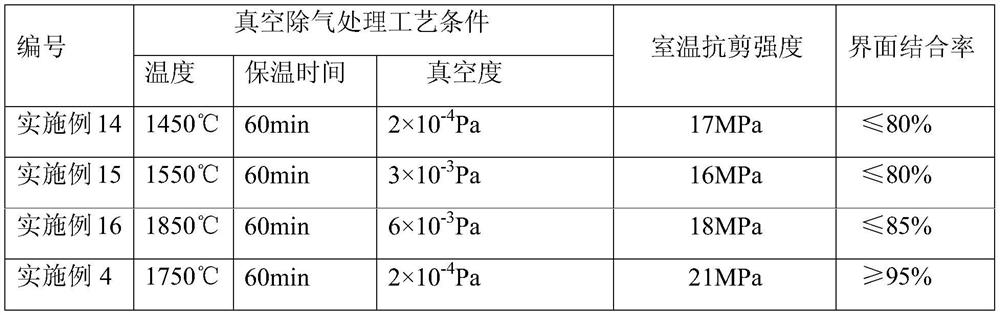

Examples

Embodiment 1

[0027] The vacuum brazing method of present embodiment molybdenum alloy and graphite is specifically as follows:

[0028] (1) After cleaning the molybdenum alloy and the graphite to be welded, put them into a high-temperature vacuum furnace for high-temperature vacuum degassing treatment. The treatment temperature is 1600°C, the holding time is 60min, and the treatment vacuum degree is 4×10 -4 Pa, cooled to less than 100 ℃ out of the furnace.

[0029] (2) Vacuum packaging the molybdenum alloy to be welded out of the oven, place a piece of titanium sheet with a thickness of 0.3mm on the surface of the graphite to be welded to be welded, and put it into a vacuum furnace together to activate the graphite to be welded, The treatment temperature is 1720°C, the holding time is 20min, and the vacuum degree is 4.5×10 -4 Pa, cooled to within 60°C and released from the furnace to obtain activated graphite.

[0030] (3) the Ti90Cr5Ta that thickness is 0.2mm is inserted between the surf...

Embodiment 2

[0033] The vacuum brazing method of present embodiment molybdenum alloy and graphite is specifically as follows:

[0034] (1) After cleaning the molybdenum alloy and the graphite to be welded, put them into a high-temperature vacuum furnace for high-temperature vacuum degassing treatment. The treatment temperature is 1550°C, the holding time is 50min, and the treatment vacuum degree is 3×10 -4 Pa, cooled to less than 100 ℃ out of the furnace.

[0035] (2) Vacuum-encapsulate the molybdenum alloy to be welded out of the furnace, place a piece of titanium sheet with a thickness of 0.4mm on the surface of the graphite to be welded, and put it into the vacuum furnace together with the surface to be welded of the graphite to be welded. Activation treatment, the treatment temperature is 1750°C, the holding time is 30min, and the vacuum degree is 4.5×10 -4 Pa, cooled to within 60°C and released from the furnace to obtain activated graphite.

[0036] (3) between the surface to be wel...

Embodiment 3

[0039] The vacuum brazing method of present embodiment molybdenum alloy and graphite is specifically as follows:

[0040] (1) After cleaning the molybdenum alloy and the graphite to be welded, put them into a high-temperature vacuum furnace for high-temperature vacuum degassing treatment. The treatment temperature is 1550°C, the holding time is 35min, and the treatment vacuum degree is 3.5×10 -4 Pa, cooled to less than 100 ℃ out of the furnace.

[0041] (2) Vacuum packaging the molybdenum alloy to be welded out of the furnace, place a piece of titanium sheet with a thickness of 0.2mm on the surface of the graphite to be welded, and put it into the vacuum furnace together to activate the graphite to be welded, The treatment temperature is 1700°C, the holding time is 25min, and the vacuum degree is 3×10 -4 Pa, cooled to within 60°C and released from the furnace to obtain activated graphite.

[0042] (3) Ti85Cr10Ta5 (that is, in the solder, the mass percentage of Ti is 85% in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com