Stainless steel clad plate used for railway equipment

A technology of stainless steel and composite panels, applied in the direction of coating, layered products, metal layered products, etc., can solve the problems of great influence of weather, environmental pollution, loud noise, etc., and achieve high yield strength and tensile strength , Guarantee the effect of corrosion resistance and structural degree, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

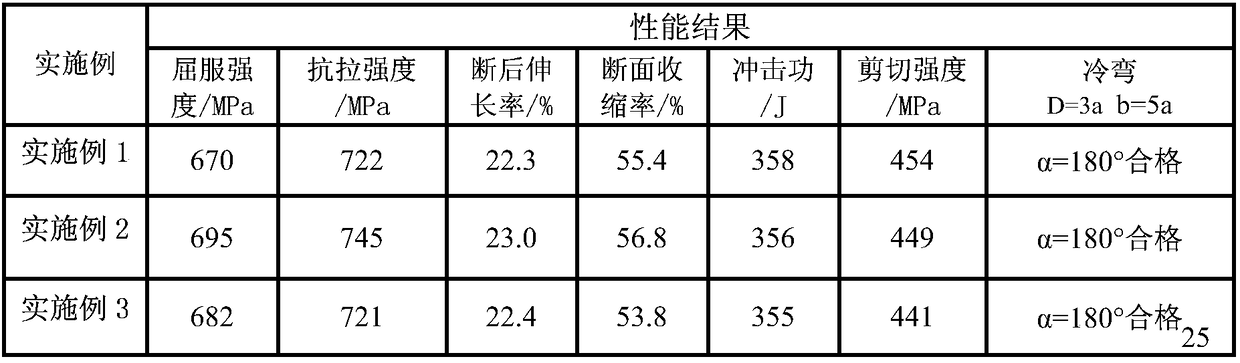

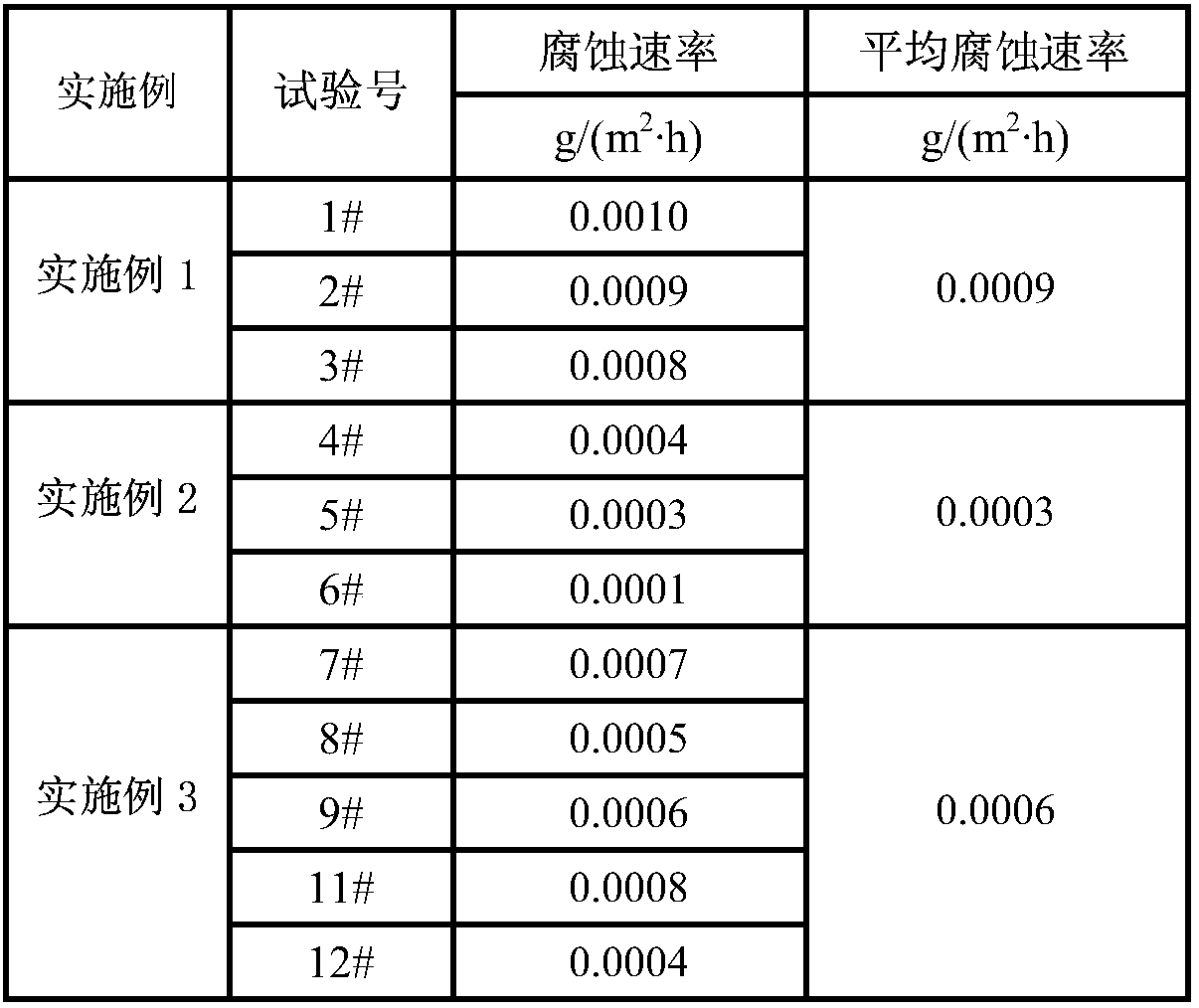

Examples

Embodiment 1

[0011] This embodiment is a stainless steel clad plate for railway equipment, which is hot-rolled from one base material and one composite material.

[0012] The chemical composition of the substrate by weight percentage is: C: 0.19%, Si: 0.6%, Mn: 0.84%, P: 0.005%, S: 0.005%, Nb: 0.06%, V: 0.45%, Ti: 0.023%, Alt : 0.045%, Cr: 0.11%, Ni: 0.33%, Cu: 0.15%, the balance is Fe and a small amount of unavoidable impurities.

[0013] The chemical composition of the composite material by weight percentage is: C: 0.11%, Si: 1.1%, Mn: 1.3%, P: 0.01%, S: 0.01%, Ni: 7.5%, Mo: 4.5%, Cr: 20.5%, N : 0.23%, the balance is Fe and a small amount of unavoidable impurities.

[0014] The anticorrosion release agent includes the following components in parts by mass: water-based epoxy resin emulsion: 15 parts, polytetrafluoroethylene emulsion: 10 parts, aluminum oxide: 87 parts, dispersant: 1 part, diluent: 2 parts, curing Accelerator DMP-30: 1 part, foaming agent: 3 parts, modified magnesium hyd...

Embodiment 2

[0028] This embodiment is a stainless steel clad plate for railway equipment, which is hot-rolled from one base material and one composite material.

[0029] The chemical composition of the substrate by weight percentage is: C: 0.20%, Si: 0.7%, Mn: 0.85%, P: 0.003%, S: 0.003%, Nb: 0.063%, V: 0.46%, Ti: 0.024%, Alt : 0.046%, Cr: 0.12%, Ni: 0.34%, Cu: 0.16%, the balance is Fe and a small amount of unavoidable impurities;

[0030] The chemical composition of the composite material by weight percentage is: C: 0.12%, Si: 1.2%, Mn: 1.4%, P: 0.03%, S: 0.02%, Ni: 7.6%, Mo: 4.6%, Cr: 20.6%, N : 0.24%, the balance is Fe and a small amount of unavoidable impurities;

[0031] The anticorrosion release agent includes the following components in parts by mass: water-based epoxy resin emulsion: 18 parts, polytetrafluoroethylene emulsion: 13 parts, aluminum oxide: 88 parts, dispersant: 2 parts, diluent: 3 parts, curing Accelerator DMP-30: 2 parts, foaming agent: 4 parts, modified magnesium ...

Embodiment 3

[0045] This embodiment is a stainless steel clad plate for railway equipment, which is hot-rolled from one base material and one composite material.

[0046] The chemical composition of the substrate by weight percentage is: C: 0.21%, Si: 0.8%, Mn: 0.86%, P: 0.002%, S: 0.002%, Nb: 0.064%, V: 0.47%, Ti: 0.025%, Alt : 0.047%, Cr: 0.13%, Ni: 0.35%, Cu: 0.17%, the balance is Fe and a small amount of unavoidable impurities.

[0047] The chemical composition of the composite material by weight percentage is: C: 0.13%, Si: 1.3%, Mn: 1.5%, P: 0.01%, S: 0.01%, Ni: 7.7%, Mo: 4.7%, Cr: 20.7%, N : 0.25%, the balance is Fe and a small amount of unavoidable impurities.

[0048] The anticorrosion release agent includes the following components in parts by mass: water-based epoxy resin emulsion: 20 parts, polytetrafluoroethylene emulsion: 15 parts, aluminum oxide: 89 parts, dispersant: 3 parts, diluent: 4 parts, curing Accelerator DMP-30: 3 parts, foaming agent: 5 parts, modified magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com