Preparation method of laminated glass glue with high bonding strength

A laminated glass, strength technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of low bonding strength, difficult fast curing, etc., and achieve the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

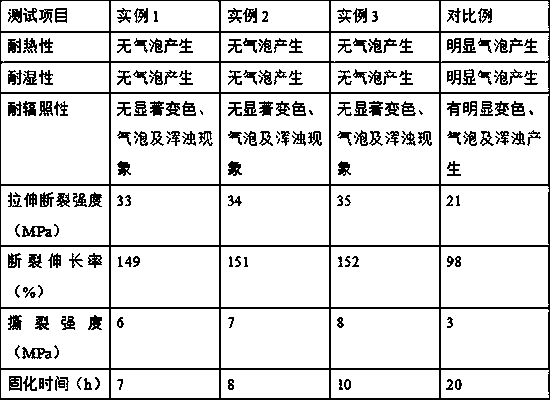

Examples

example 1

[0023] Mix silane coupling agent KH-560, anhydrous isopropanol and deionized water in a volume ratio of 3:1:2 and put them in a beaker for hydrolysis reaction for 16 minutes to obtain a self-made hydrolyzate. Silica sol with a mass fraction of 15% and The self-made hydrolyzate was mixed in a container at a volume ratio of 1:2, and mixed and reacted at a temperature of 65°C for 1 hour to obtain a modified silica sol; weigh 45 mL of polycaprolactone diol with a mass fraction of 15% and add it to the container In a four-necked flask with a stirrer, a thermometer and a condenser tube, stir at a temperature of 80° C. for 16 minutes, then dehydrate under reduced pressure for 45 minutes to obtain a stirred product, and then add toluene diisocyanate with a stirred product mass of 8% to the four-necked flask, Continue to insulate and mix the reaction for 16 minutes to obtain the reaction solution, and continue to mix the reaction solution, hydroxyethyl acrylate, hydroquinone and 20% hyd...

example 2

[0025]The silane coupling agent KH-560, anhydrous isopropanol and deionized water were mixed in a beaker with a volume ratio of 3:1:2 and hydrolyzed for 18 minutes to obtain a self-made hydrolyzate. Silica sol with a mass fraction of 15% and The self-made hydrolyzate was mixed in a container at a volume ratio of 1:2, and mixed and reacted at a temperature of 70°C for 2 hours to obtain a modified silica sol; 55 mL of polycaprolactone diol with a mass fraction of 15% was weighed and added to the container In a four-necked flask with a stirrer, a thermometer and a condenser tube, stir at a temperature of 90°C for 18 minutes, then dehydrate under reduced pressure for 50 minutes to obtain a stirred substance, then add toluene diisocyanate with a stirring substance mass of 8% to the four-necked flask, Continue to insulate and mix the reaction for 18 minutes to obtain the reaction solution. Continue to mix the reaction solution, hydroxyethyl acrylate, hydroquinone and 20% hydrogen per...

example 3

[0027] Mix silane coupling agent KH-560, anhydrous isopropanol and deionized water in a volume ratio of 3:1:2 and put them in a beaker for hydrolysis reaction for 20 minutes to obtain a self-made hydrolyzate. Silica sol with a mass fraction of 15% and The self-made hydrolyzate was mixed in a container at a volume ratio of 1:2, and mixed and reacted at a temperature of 75°C for 3 hours to obtain a modified silica sol; 65 mL of polycaprolactone diol with a mass fraction of 15% was weighed and added to the container In a four-necked flask with a stirrer, a thermometer and a condenser tube, stir at a temperature of 100° C. for 20 minutes, and then dehydrate under reduced pressure for 60 minutes to obtain a stirred substance, and then add toluene diisocyanate with a stirring substance mass of 8% to the four-necked flask, Continue to insulate and mix the reaction for 20 minutes to obtain the reaction solution, and continue to mix the reaction solution, hydroxyethyl acrylate, hydroqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com