Liquid increasing agent for delayed coking of oil refining process

A delayed coking and oil refining process technology, applied in cracking, petroleum industry, hydrocarbon oil treatment, etc., can solve problems such as coking and fouling of anti-coking and yield-increasing agents, affecting the yield of light oil products, and serious coking of residual oil, etc., to achieve Prevent scaling and corrosion, reduce coke and dry gas yield, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

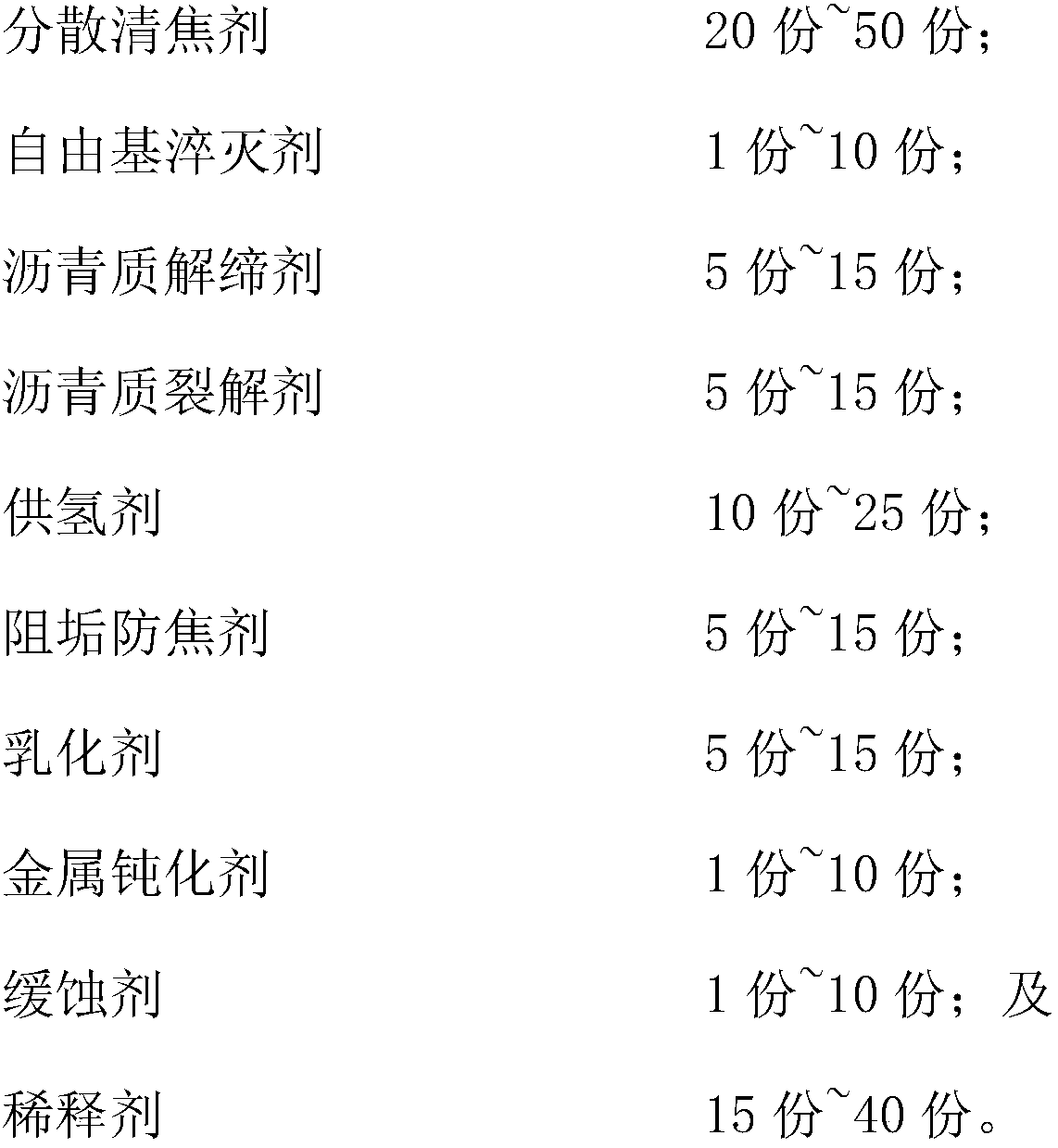

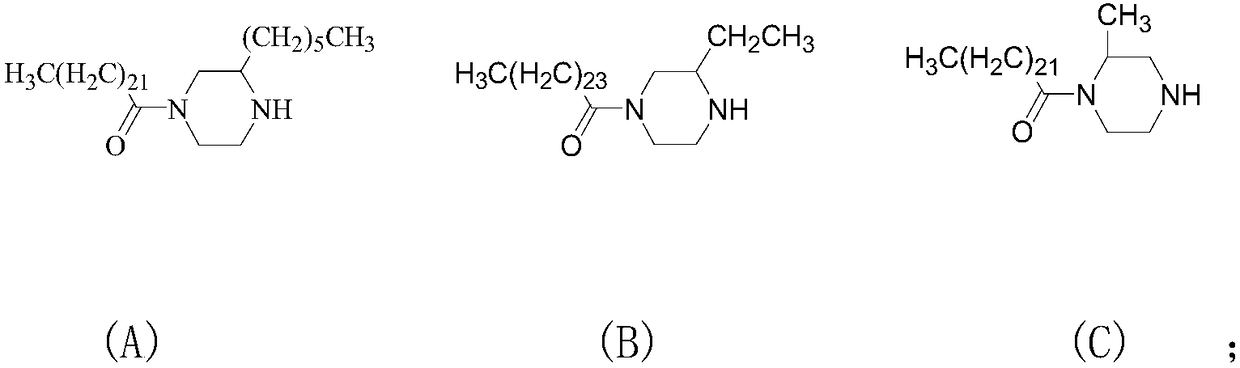

[0041] According to the mass parts in Table 1, disperse coke cleaner, free radical quencher, asphaltene deassociating agent, asphaltene cracking agent, hydrogen donor, scale inhibitor and anti-scorch agent, emulsifier, metal passivator, retarder Put the etchant and diluent into the container, heat up while stirring, stir at 80°C for 1 hour, and filter to remove impurities after cooling to obtain different types of liquid income increase agent samples:

[0042] Table 1

[0043]

[0044]

[0045]

Embodiment 2

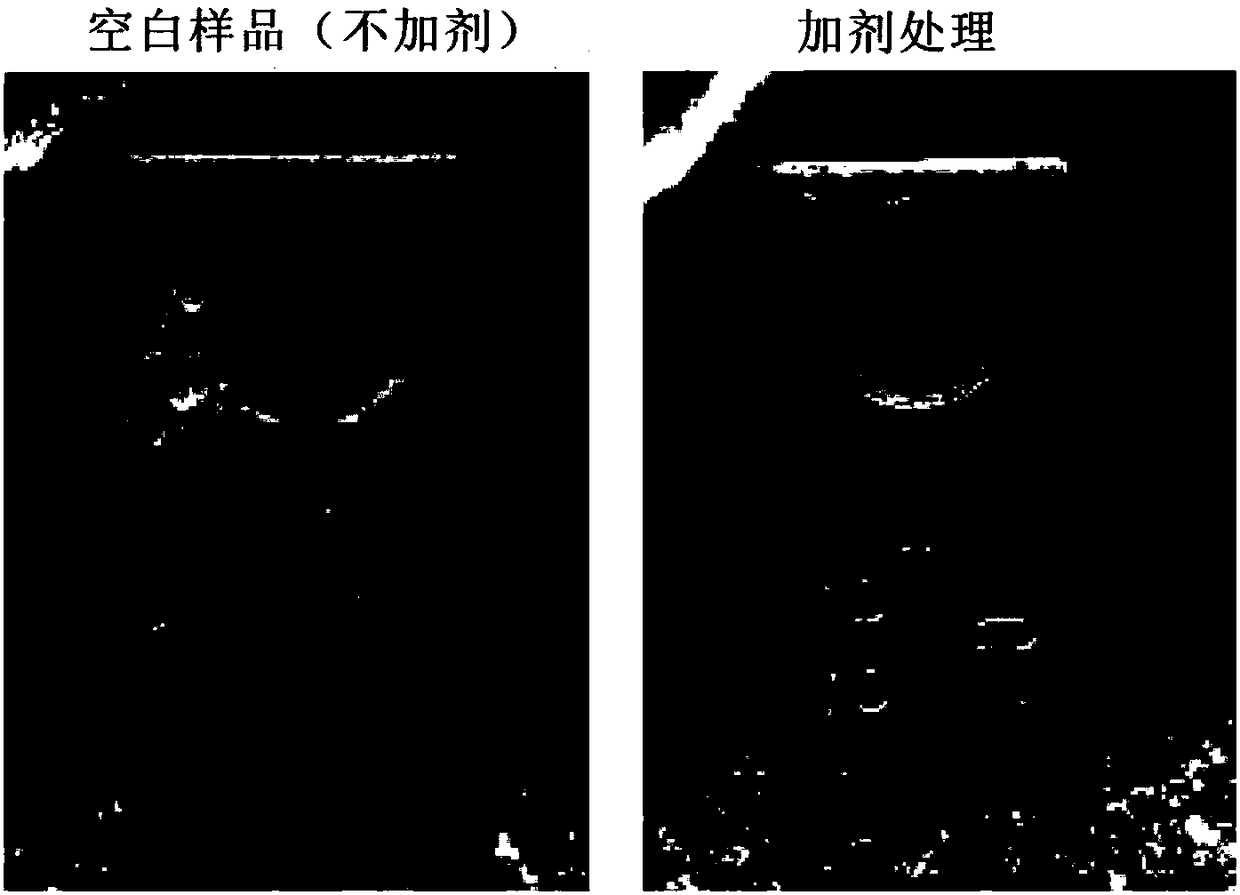

[0047]The effect evaluation of liquid income increase agent was carried out in the delayed coking workshop of Liaohe Petrochemical Company. The ZK-818 coking liquid income increase agent developed by Yixing Zhongdakai Chemical Co., Ltd. was used as a comparison. The specific operating parameters are as follows: reaction temperature 480 ° C for 2 hours, regeneration temperature React at 650°C for 2 hours, the preheating temperature of the raw material oil is 250°C, the dosage of the liquid income increase agent is 100ppm, the added amount is calculated by the raw material oil, and the raw material oil is taken from Liaohe vacuum residue.

[0048] Table 2

[0049]

[0050]

[0051] Note: 1) Light oil % = (gasoline + diesel) %;

[0052] 2) Total liquid yield % = (liquefied petroleum gas + gasoline + diesel oil)%.

[0053] As can be seen from the data in Table 2, adding the liquid yield increaser of the present invention can significantly increase the yield of light oil and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com