Magnetic ferroferric oxide polylactic acid melt-blowing non-woven material and preparation method

A technology of ferric oxide polylactic acid and non-woven materials, applied in the direction of single-component polyester rayon, etc., can solve the problems of waste environmental pollution, disappearance, poor electret durability, etc., and achieves a simple preparation method and improved Filterable, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

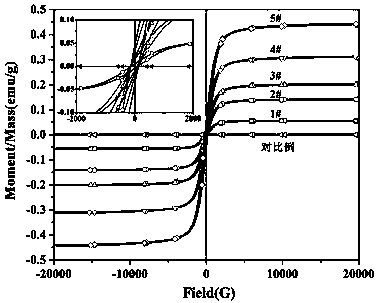

[0027] see image 3 .

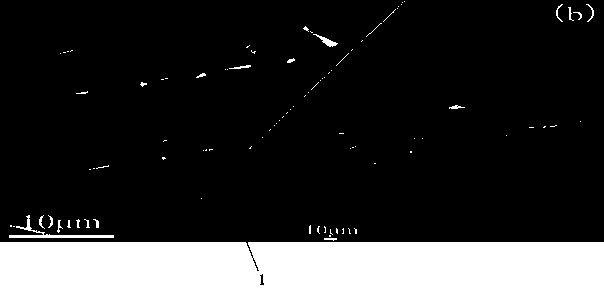

[0028] This embodiment is a magnetic ferroferric oxide polylactic acid melt-blown nonwoven material, including a layered magnetic composite layer, the magnetic composite layer is formed by intertwining magnetically degradable fibers 1, and air holes are formed between the magnetically degradable fibers 1, and the magnetically degradable Fiber 1 has a fiber diameter of 1-10 μm.

[0029] This embodiment also provides a method for preparing a magnetic ferroferric oxide polylactic acid melt-blown nonwoven material, including the following steps: Step ①: preparation of a magnetic triiron tetroxide polylactic acid composite chip, including pre-blending and melt blending.

[0030] Pre-blending: Dry the polylactic acid masterbatch and ferric oxide powder in a drying oven at 80°C for 12h and 3h respectively in proportion, put the dried ferric oxide powder into a high-speed mixer for pre-blending Stir for 5 minutes, then add additives in proportion and stir for...

Embodiment 2

[0045] This embodiment is a magnetic ferroferric oxide polylactic acid melt-blown nonwoven material, including a layered magnetic composite layer, the magnetic composite layer is formed by intertwining magnetically degradable fibers 1, and air holes are formed between the magnetically degradable fibers 1, and the magnetically degradable Fiber 1 has a fiber diameter of 1-10 μm.

[0046] The present embodiment also provides the preparation method of magnetic triiron tetroxide polylactic acid melt blown nonwoven material, comprises the steps:

[0047] Step ①: Preparation of magnetic triiron tetroxide-polylactic acid composite chips, including pre-blending and melt-blending.

[0048] Pre-blending: Dry the polylactic acid masterbatch and ferric oxide powder in a drying oven at 80°C for 12h and 3h respectively in proportion, put the dried ferric oxide powder into a high-speed mixer for pre-blending Stir for 5 minutes, then add additives in proportion and stir for 15 minutes to infi...

Embodiment 3

[0059] see Figure 4 .

[0060] This embodiment is a magnetic ferroferric oxide polylactic acid melt-blown nonwoven material, including a layered magnetic composite layer, the magnetic composite layer is formed by intertwining magnetically degradable fibers 1, and air holes are formed between the magnetically degradable fibers 1, and the magnetically degradable Fiber 1 has a fiber diameter of 1-10 μm.

[0061] The present embodiment also provides the preparation method of magnetic triiron tetroxide polylactic acid melt blown nonwoven material, comprises the steps:

[0062] Step ①: Preparation of magnetic triiron tetroxide-polylactic acid composite chips, including pre-blending and melt-blending.

[0063] Pre-blending: Dry the polylactic acid masterbatch and ferric oxide powder in a drying oven at 80°C for 12h and 3h respectively in proportion, put the dried ferric oxide powder into a high-speed mixer for pre-blending Stir for 5 minutes, then add additives in proportion and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com