Technology of planarizing ridge waveguide device by using polyimide

A technology of polyimide and ridge waveguide, which is applied in the direction of optical waveguide and light guide, can solve the problems of poor repeatability and complex planarization process, achieve small radiation damage, small ion bombardment damage, reduce device damage analysis and planarization process effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

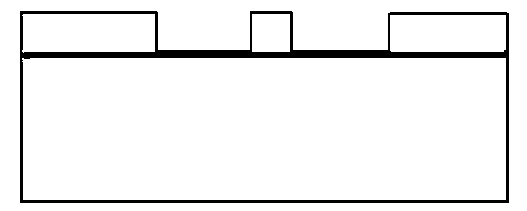

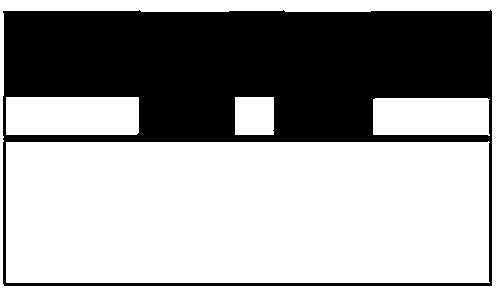

[0019] Embodiment 1: A kind of technology that polyimide makes ridge waveguide device planarization, the steps are as follows: S1, polyimide is coated on the surface of the sample, and the sample is a double-groove ridge laser, such as figure 1 As shown, after coating as figure 2 shown.

[0020] S2, the polyimide on the sample is cured, the flow of protective nitrogen gas is 30sccm during curing, the structure diagram after curing is as follows image 3 shown.

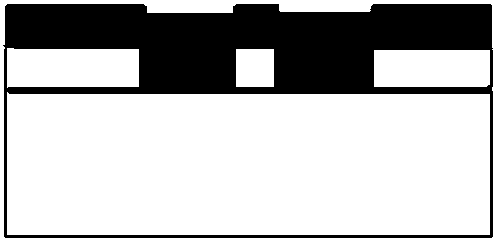

[0021] S3. Etch the cured polyimide on the surface of the sample through a microwave degumming machine. The power of the microwave degumming machine is 50W~120W, and the flow rate of oxygen is 20sccm~200sccm. The etching time depends on the depth of the groove and the thickness of the glue. implementation; after etching as Figure 4 shown.

Embodiment 2

[0022] Example 2: A process for flattening a ridge waveguide device by polyimide, taking a double-groove ridge-shaped high-frequency laser with a wavelength of 1.3 / 1.5um as an example, the width of the ridge-shaped mesa in the active layer is 2um, and both sides The channel width is 7 um, the channel depth is 1.7 um, the profile is as follows Figure 5 ; After implementing the process technology of the present invention, the polyimide embeds the local channel effect of the ridge structure device, and the profile is as follows Figure 6 .

[0023] The operation is as follows: step 1, homogenize the polyimide on the surface of the sample, and coat it with a homogenizer, the speed of the homogenizer is 5000 rpm, and the thickness of the coated polyimide after curing is 2 times the depth of the trench to be buried. ~3 times. And ZKPI-540 photosensitive polyimide or non-photosensitive polyimide or BCB can be used.

[0024] Step 2, the sample is cured, and the temperature and tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com