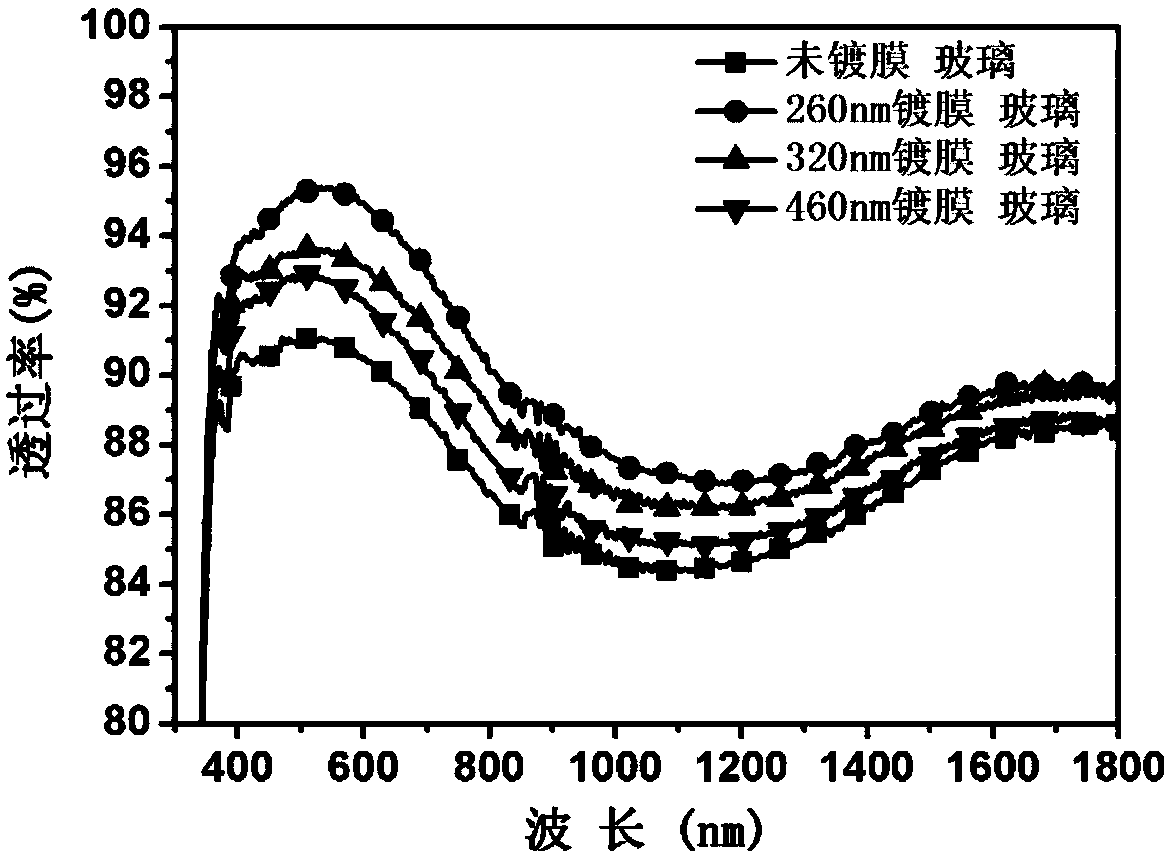

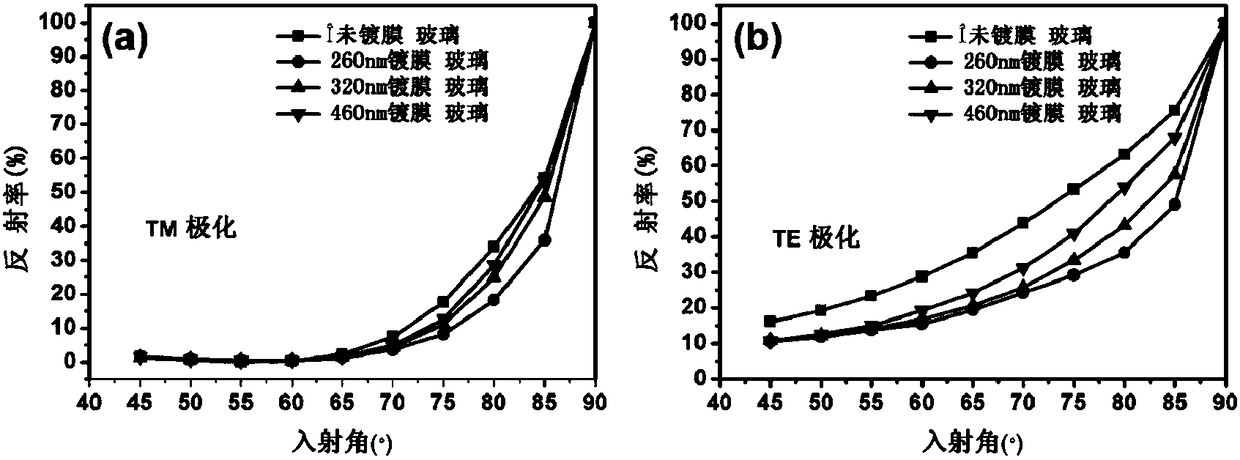

Two-dimensional ordered porous nano silicon oxide antireflection film having hydrophobic effect

A technology of porous silica and silica, applied in the direction of coating, etc., can solve the problems of easy attenuation of transmittance, single anti-reflection angle, and narrow wavelength range of high-efficiency anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Preparation of Porous Silica Nano Membrane Material

[0061] The preparation method of porous silicon dioxide nano-membrane material of the present invention comprises the following steps:

[0062] (1) providing a suspension of polymer microspheres and an organic-inorganic silicon source;

[0063] In the presence of an alkaline reagent (the alkaline reagent is usually ammonia water), the polymer microspheres react with an organic-inorganic silicon source to obtain a silica-coated polymer microsphere with a particle size of 250-500 nm. spherical core-shell particles;

[0064] Usually, the polymer microspheres are polystyrene microspheres with a particle diameter of 240-440 nm.

[0065] The organic-inorganic silicon source includes an orthosilicate compound and a silane compound in a ratio of 1:0.5 to 10; wherein, the orthosilicate compound includes (but is not limited to): orthosilicate Methyl orthosilicate, orthobutyl silicate, or combinations thereof; the silane com...

Embodiment 1

[0087] Take 1.5g of polyvinylpyrrolidone (average relative molecular weight 58000), 0.5g of potassium persulfate, 100mL of distilled water, stir at room temperature, after the solution is clarified, add 11mL of styrene monomer, and pass through N 2 0.5h; then at 40°C, with a stirring speed of 300rpm, and stirring for 12h, a polystyrene emulsion with an average particle size of about 240nm can be obtained.

[0088] Take 0.71g of the polystyrene emulsion obtained above, dissolve it in 40mL of absolute ethanol, and disperse it fully by ultrasonication for 30min to obtain a 5.0wt% suspension; at 20°C, the stirring speed is 300rpm, Add 2mL of ammonia water to the suspension, and after 5min, add 0.5mL of organic-inorganic silicon source, tetraethylorthosilicate and methyltriethoxysilane with a silicon source volume ratio of 2:1, and react for 0.5h to obtain Silica-coated polystyrene nanoparticles with an average particle size of around 260 nm.

[0089] The silicon oxide-coated pol...

Embodiment 2

[0093] Take 1.0g of polyvinylpyrrolidone (average relative molecular weight 58000), 0.68g of azobisisobutyramide hydrochloride, 100mL of distilled water, stir at room temperature, and after the solution is clarified, add 11mL of styrene monomer, and pass into N 2 2h; then at 70°C with a stirring speed of 200rpm, stirring for 24h to obtain a polystyrene emulsion (PS) with an average particle diameter of about 300nm.

[0094] Take 5.0 g of the polystyrene emulsion obtained above, dissolve it in 40 mL of absolute ethanol, and ultrasonically dissolve it for 30 minutes to obtain a 7.0 wt % suspension; at 50 ° C, the stirring speed is 200 rpm. Add 5mL of ammonia water to the suspension, and after 5min, add 1.5mL of organic-inorganic silicon source, tetraethyl orthosilicate and methyltriethoxysilane with a silicon source volume ratio of 1:3, react for 3h, and obtain the average particle size Silica-coated polystyrene particles with a diameter of about 320 nm.

[0095] The silicon o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com