Permanent weather-proof crosslinked polyethylene insulation material

An insulating material, low-density polyethylene technology, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as limited weather resistance, reduce water absorption, improve weather resistance, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

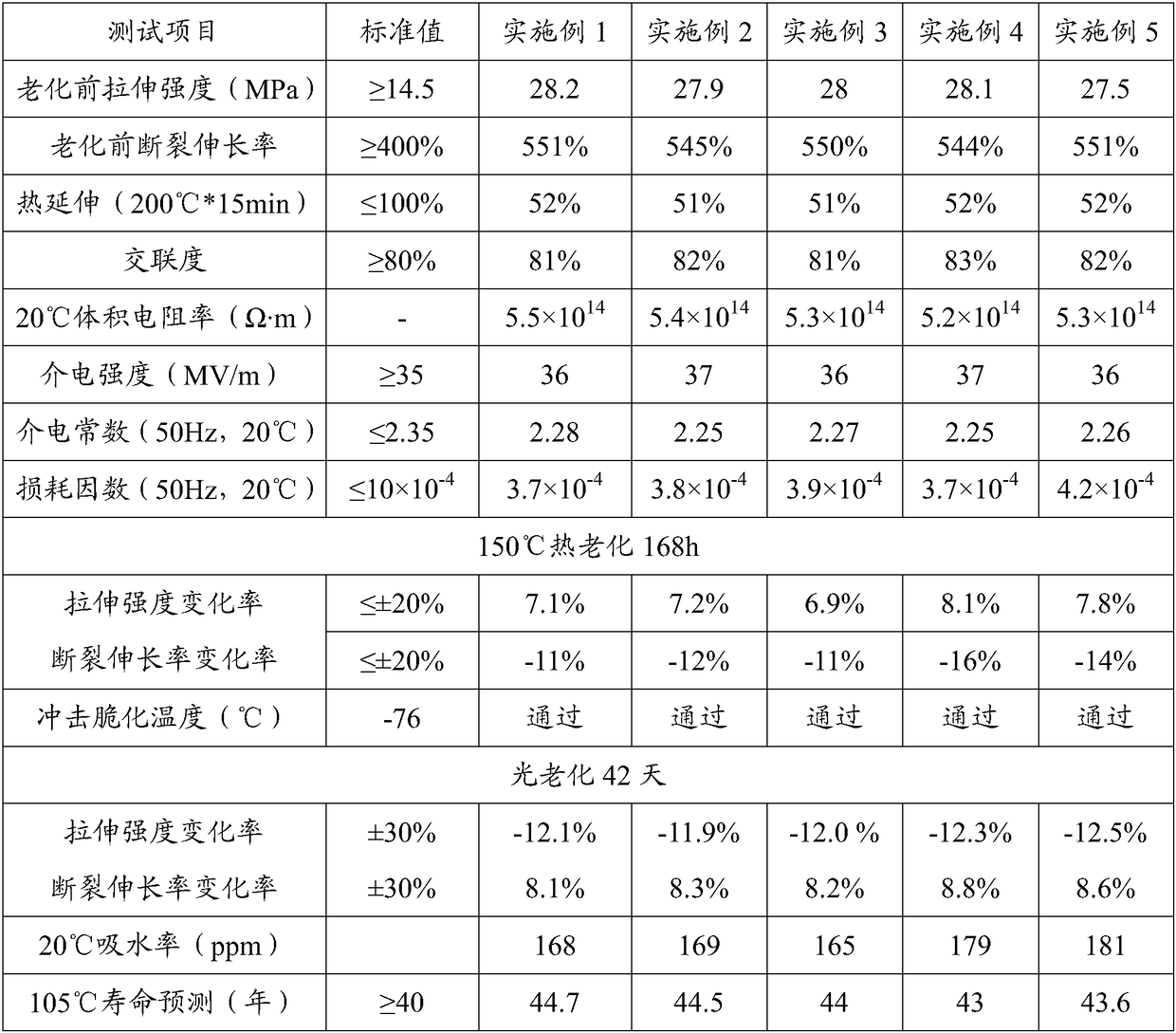

Examples

Embodiment 1

[0024] This embodiment provides a kind of insulation material, and its raw material comprises by weight:

[0025] 100g low density polyethylene, 1.5g Super P carbon black, 2.2g dicumyl peroxide, 0.5g antioxidant 1035, 0.2g polyvinylidene fluoride. The density of low density polyethylene used is 0.920±0.003g / cm 3 , the melt flow index is 2.5g / 10min, the sulfur content of the carbon black used is 100ppm, the ash content is 100ppm, and the particle size is 10nm.

[0026] The preparation method of this material is as follows: feed the screw extruder after mixing the low-density polyethylene, Super P carbon black, antioxidant 1035 and polyvinylidene fluoride of the above-mentioned quality, then 2.2g of dicumyl peroxide Inject into the above-mentioned screw extruder through the pump and the side feed port, control the temperature of each zone at 110-120°C, carry out melt extrusion and granulation, and then cool down to obtain the insulating material.

Embodiment 2

[0028] The cross-linked polyethylene insulating material provided in this embodiment, its raw material comprises by weight:

[0029] 100g of low-density polyethylene, 1g of Super P carbon black, 1g of bis-tert-butylperoxydicumene, 0.1g of antioxidant 736, and 1g of polyhexafluoropropylene. The density of low density polyethylene used is 0.920±0.003g / cm 3 , the melt flow index is 3g / 10min, the sulfur content of the carbon black used is 500ppm, the ash content is 300ppm, and the particle size is 10nm.

[0030] The preparation method of this material is as follows: feed the screw extruder after mixing the low-density polyethylene, Super P carbon black, antioxidant 736 and polyhexafluoropropylene of the above-mentioned quality, and then add 1g of bis-tert-butyl peroxy diiso The propylene benzene is injected into the above-mentioned screw extruder through the pump and the side feed port, and the temperature of each zone is controlled at 110-120°C, melt-extruded and granulated, and...

Embodiment 3

[0032] The cross-linked polyethylene insulating material provided in this embodiment, its raw material comprises by weight:

[0033] 100g low-density polyethylene, 3g Super P carbon black, 3g dicumyl peroxide, 0.5g β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and 1g poly Mixture of hexafluoropropylene and silicone resin. The density of low density polyethylene used is 0.920±0.003g / cm 3 , the melt flow index is 2g / 10min, the sulfur content of the carbon black used is 250ppm, the ash content is 500ppm, and the particle size is 15nm.

[0034] The preparation method of this material is as follows: low-density polyethylene of above-mentioned quality, Super P carbon black, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.5g Polyhexafluoroethylene and 0.5g of silicone resin are mixed and fed into the screw extruder, and then 3g of dicumyl peroxide is injected into the above screw extruder through the pump and the side feed port, and the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com