Dual-ring nested two-phase integrated anaerobic reactor

An anaerobic reactor, an integrated technology, applied in the direction of gas production bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem that the anaerobic reactor occupies a large area , complex operation and maintenance of the system, short service life and other problems, to achieve the effect of compact structure, improved system stability, and saved floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

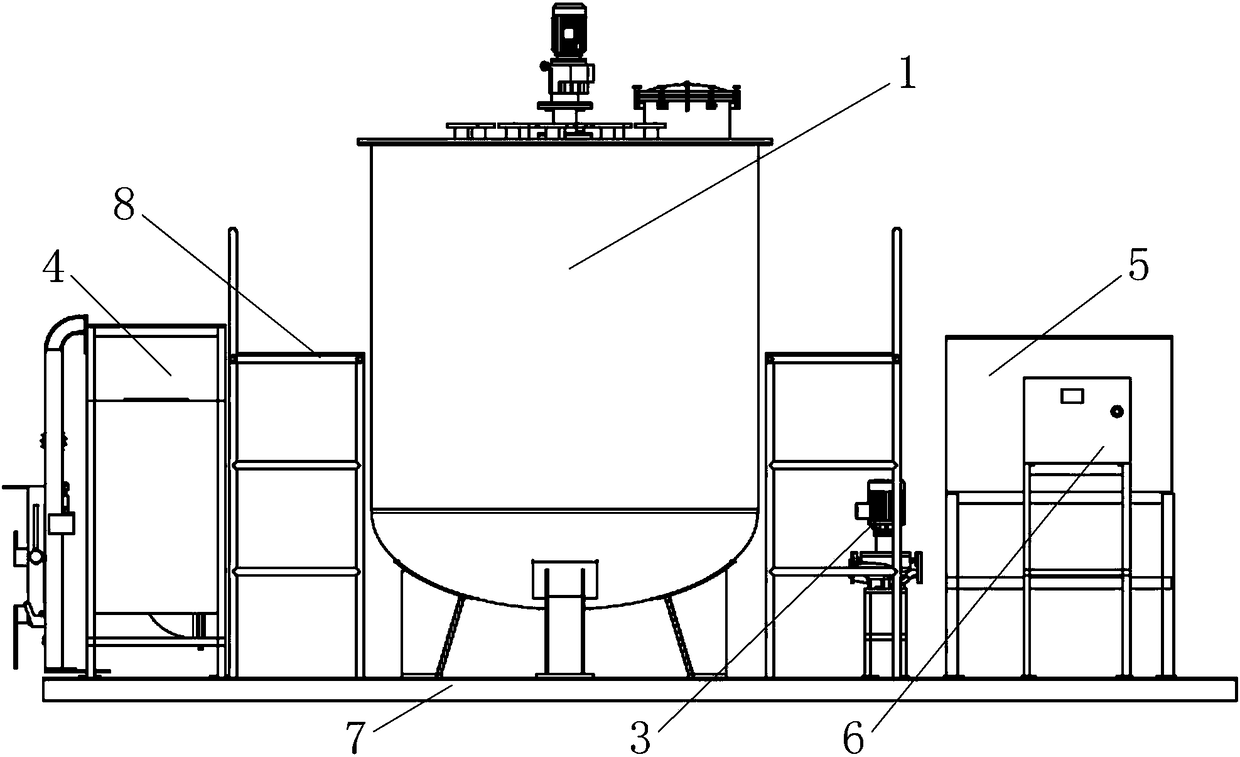

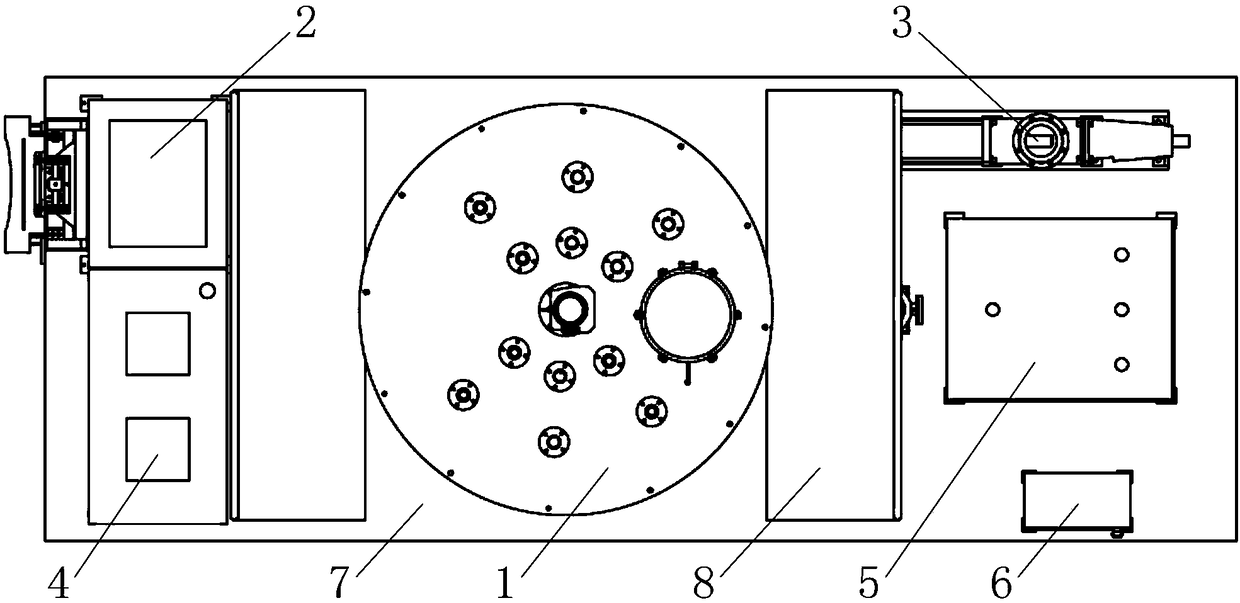

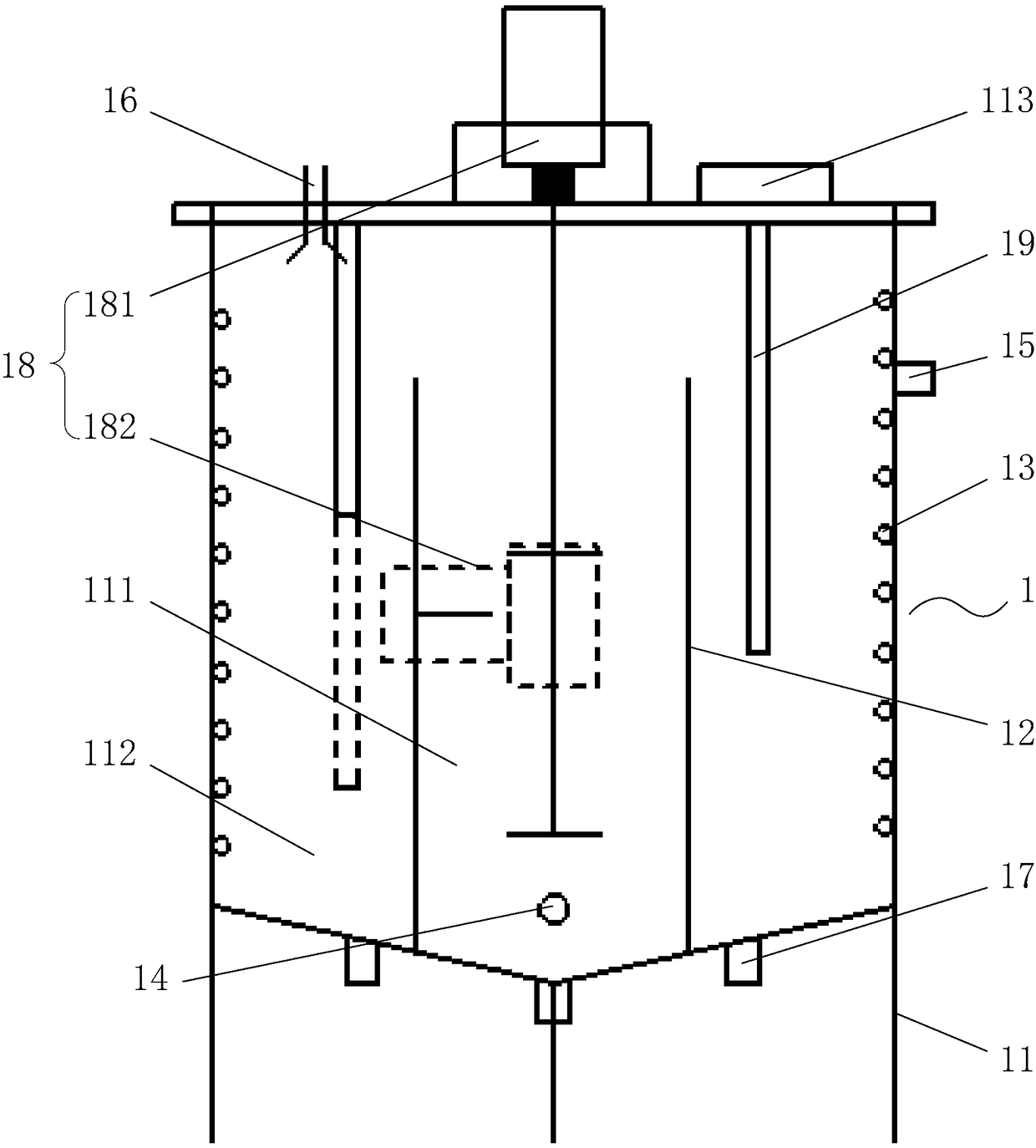

[0019] Such as figure 1 with figure 2 As shown, a double-ring nested two-phase integrated anaerobic reactor provided by the present invention includes an anaerobic digestion tank 1, a feed tank 2, a feed pump 3, a biogas residue biogas slurry tank 4, a heating water tank 5 and Electrical control cabinet6. Among them, the anaerobic digestion tank 1 adopts an inner and outer double-ring nested structure, the inner ring is used as the hydrolysis acidification phase, and the outer ring is the methanogenic phase; the feed pool 2 is used for temporarily storing feed kitchen waste; the feed pump 3 is used to The pretreated food waste is pumped into the anaerobic digestion tank 1, the feed pump 3 is a screw pump; the biogas residue digester 4 is used to temporarily store the biogas residue and biogas slurry discharged after anaerobic digestion; the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com