An improved circular aluminum melting furnace and a masonry method for the sealing edge of the castable material of the circular aluminum melting furnace

A technology of aluminum melting furnace and castable, which is applied to the masonry field of circular aluminum melting furnace and castable sealing edge of circular aluminum melting furnace, and can solve the problem of easy wear and tear of refractory brick sealing edge, delay in process production, long construction period, etc. problems, to achieve the effect of short construction period, reduced production loss, and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

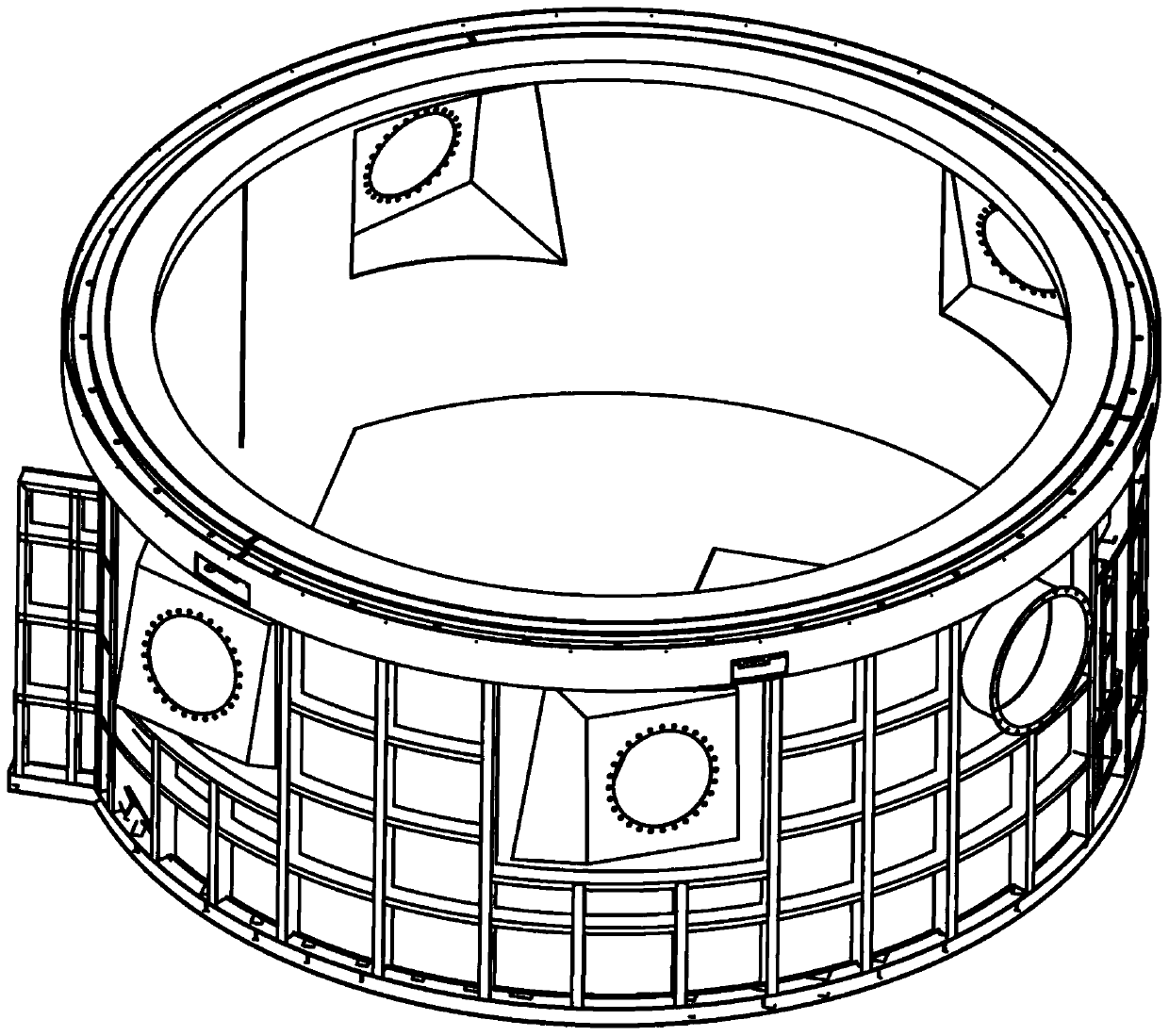

[0069] see figure 1 , figure 1 A schematic diagram of the improved circular aluminum melting furnace structure provided by Example 1 of the present invention.

[0070] The mixed material is obtained after the medium castable is fully mixed with the stainless steel fiber accounting for 2%. Among them, the medium-quality castable is produced by Chengdu Shuye New Material Co., Ltd., Al 2 o 3 The content is 60%, the density is 2.3g / cm 3 , stainless steel fiber length is 12mm, diameter is 0.8mm.

[0071] Pour the mixture obtained in the above steps into the pouring wooden mold set around the feeding port of the circular aluminum melting furnace body, demould after the pouring material is solidified, and then gradually raise the temperature to 1050°C and bake for 7 days to obtain a circular aluminum melting furnace. Castable sealing edge of aluminum melting furnace. The diameter of the casting material sealing edge is 8.5m, and the height of the casting material sealing edge i...

Embodiment 2

[0074] The mixed material is obtained after the medium castable is fully mixed with the stainless steel fiber accounting for 1.5%. Among them, the medium-quality castable is produced by Chengdu Shuye New Material Co., Ltd., Al 2 o 3 The content is 60%, the density is 2.3g / cm 3 , stainless steel fiber length is 12mm, diameter is 0.8mm.

[0075] Pour the mixture obtained in the above steps into the pouring wooden mold set around the feeding port of the circular aluminum melting furnace body, demould after the pouring material is solidified, and then gradually raise the temperature to 1050°C and bake for 7 days to obtain a circular aluminum melting furnace. Castable sealing edge of aluminum melting furnace. The diameter of the casting material sealing edge is 8.5m, and the height of the casting material sealing edge is 400m.

[0076] After multiple batches of actual production experiments, the service life of the castable sealing edge of the improved aluminum melting furnace ...

Embodiment 3

[0078] The mixed material is obtained after the medium castable is fully mixed with the stainless steel fiber accounting for 2%. Among them, the medium-quality castable is produced by Chengdu Shuye New Material Co., Ltd., Al 2 o 3 The content is 50%, the density is 2.5g / cm 3 , stainless steel fiber length is 12mm, diameter is 0.8mm.

[0079] Pour the mixture obtained in the above steps into the pouring wooden mold set around the feeding port of the circular aluminum melting furnace body, demould after the pouring material is solidified, and then gradually raise the temperature to 1050°C and bake for 7 days to obtain a circular aluminum melting furnace. Castable sealing edge of aluminum melting furnace. The diameter of the casting material sealing edge is 8.5m, and the height of the casting material sealing edge is 400m.

[0080] After multiple batches of actual production experiments, the service life of the castable sealing edge of the improved aluminum melting furnace pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com