Preparation and application of lithium metal negative electrode based on aromatized nitrate free radical modification

A lithium metal negative electrode and aromatization technology, which is applied in the preparation and application of lithium metal negative electrodes modified by aromatized nitric acid radicals, can solve the problems of lithium dendrite safety hazards and low Coulombic efficiency, and achieve excellent electrochemical performance. Effects of Coulombic efficiency and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Under the protection of argon gas, the compound (1) containing aromatized nitric acid radicals was dissolved in dimethyl sulfoxide (DMSO) to make a solution with a mass fraction of 0.1%, and 50 μL of the solution was taken with a pipette gun Drop vertically on the surface of the lithium metal negative electrode, and coat it evenly, and leave it at room temperature for 12 hours to obtain a lithium metal negative electrode modified by aromatized nitric acid radicals, and the thickness of the protective layer is about 100nm.

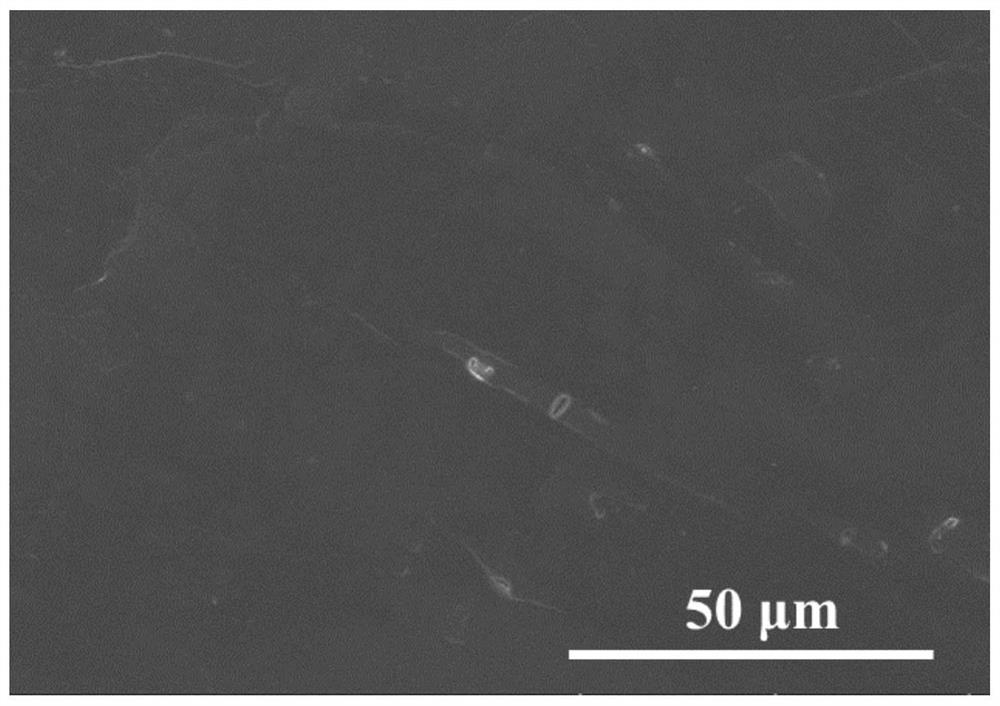

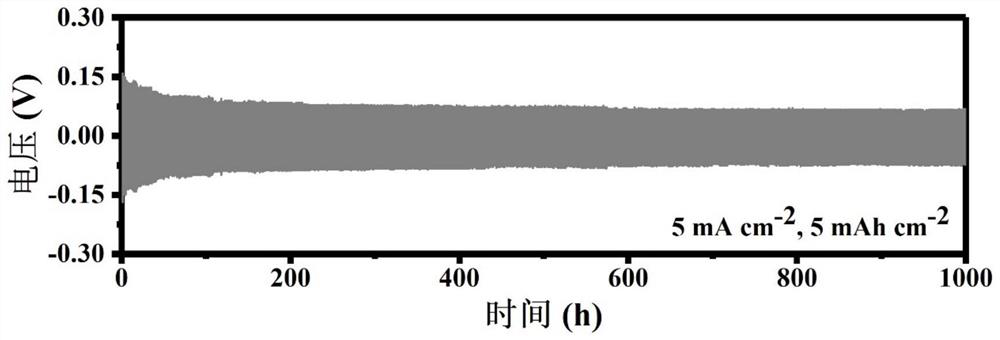

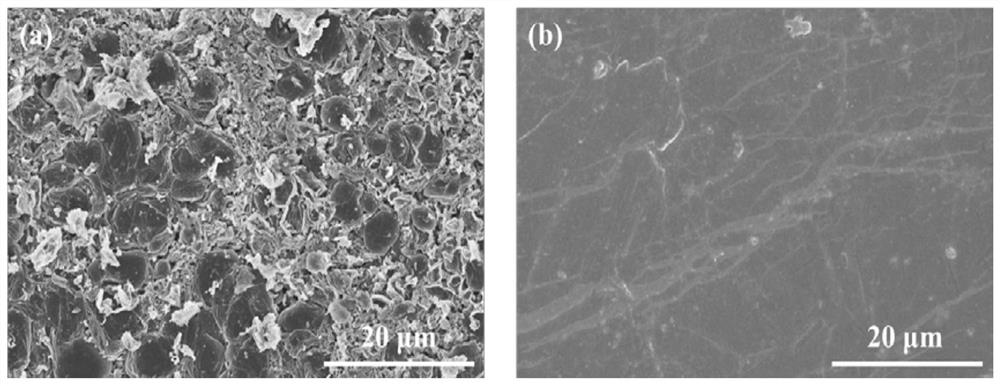

[0047] The surface of the lithium metal negative electrode modified by aromatized nitric acid radicals is smooth (see figure 1 ). The prepared lithium metal negative electrode was dissolved in 1,3-dioxane (DOL) / ethylene glycol dimethyl ether (DME) (volume ratio of 1 : 1) the mixed solution is electrolyte, 2wt% LiNO 3 As an additive, PE as a diaphragm, assembled into a Li||Li symmetrical battery, the current density is 5mA / cm 2 , the deposition cap...

Embodiment 2

[0049] Under the protection of argon gas, the compound (1) containing aromatized nitric acid radicals was dissolved in tetrahydrofuran (THF), and made into a solution with a mass fraction of 0.5%, and 50 μL of the solution was vertically dropped on the The surface of the metal lithium negative electrode is evenly coated, and left at room temperature for 12 hours to obtain a lithium metal negative electrode modified by aromatized nitric acid radicals, and the thickness of the protective layer is about 450nm.

[0050] The lithium metal negative electrode prepared by this method uses a mixed solution of 1M LiTFSI dissolved in DOL / DME (volume ratio 1:1) as the electrolyte, 2wt% LiNO 3 As an additive, PE as a diaphragm, and copper foil assembled into a Li||Cu battery, the test found that at a current density of 1mA / cm 2 , the deposition capacity is 1mAh / cm 2 Under the same conditions, its Coulombic efficiency is still 94% after 120 cycles (see Figure 4 ). Assembled with the S p...

Embodiment 3

[0052] Under the protection of argon gas, the compound (1) containing aromatized nitric acid free radicals was dissolved in N,N-dimethylformamide (DMF), and made into a solution with a mass fraction of 1.0%, and the Take 50 μL of the solution and drop it vertically on the surface of the lithium metal negative electrode, and coat it evenly, and leave it at room temperature for 12 hours to obtain a lithium metal negative electrode modified with aromatized nitric acid radicals, and the thickness of the protective layer is about 900 nm.

[0053] The lithium metal negative electrode prepared by this method is assembled into a symmetrical battery, and the current density is 10mA / cm 2 , the deposition capacity is 10mAh / cm 2 Under these conditions, the charge-discharge curve is stable, the cycle time can reach 600h, and the hysteresis voltage has also been greatly improved (see Figure 6 ). It shows that the metal lithium anode modified by aromatized nitric acid radical can effectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com