Composite material, airless tire with same and assembly method of airless tire

A technology of airless tires and composite materials, used in special tires, non-pneumatic tires, tire parts and other directions, can solve the problems of large mechanical vibration, heavy tire weight, reduced riding comfort, etc., and achieve excellent cushioning performance and assembly. The method is simple, the effect of strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment 1 discloses a composite material, which is composed of the following components in terms of mass percentage: carbon fiber: 1-5%, graphite powder: 0.5-3%, catalyst NaOH solid: 0.1-1%, co-catalyst acetyl caprolactam: 0.1~1%, the rest is caprolactam.

Embodiment 2

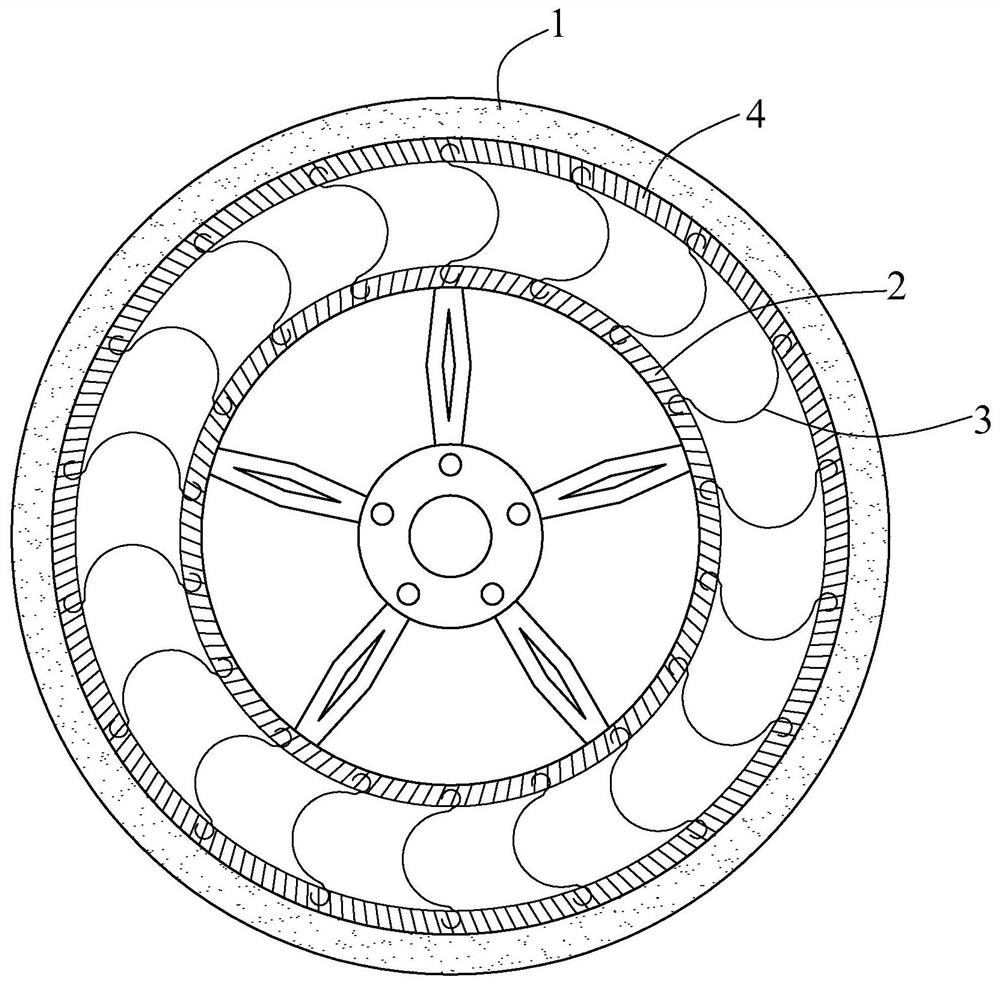

[0035] see Figure 1 to Figure 3 .

[0036] Embodiment 2 discloses an airless tire, which includes a tire tread 1 , an inner hub 2 and an outer rim 4 . Tire tread 1 adopts rubber tread, and it is sleeved on the outer rim 4. The inner hub 2 is connected to the outer rim 4 through spoke plates 3 distributed along the circumferential direction. The outer rim 4 is made of the composite material described in Embodiment 1, and the mechanical strength, impact resistance, toughness and weight of the outer rim made of the composite material are better than those of strip steel.

[0037] In addition, the inner hub 2 is made of traditional aluminum or the composite material described in Embodiment 1. It is found through actual production tests that the performance of the inner hub 2 made of composite material is better than that of aluminum and the inner hub made of composite material is more convenient for subsequent assembly, so in this embodiment 2, the inner hub 2 is also made of ...

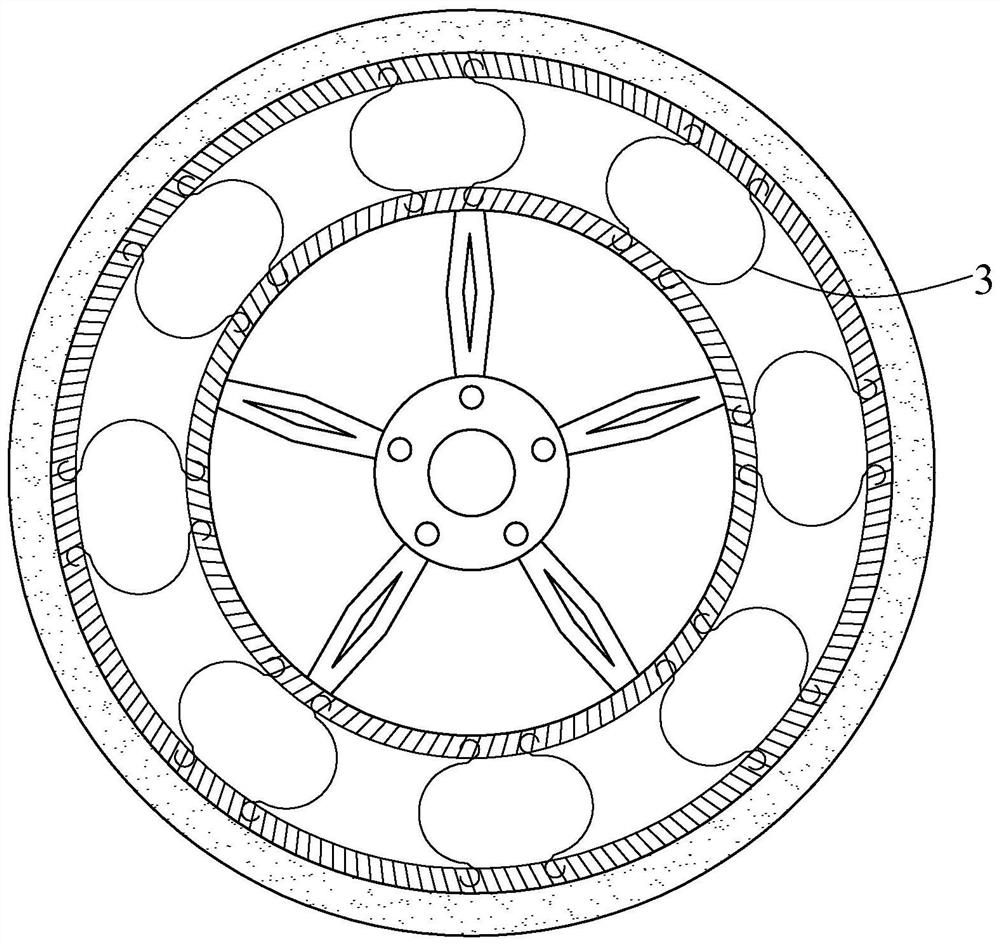

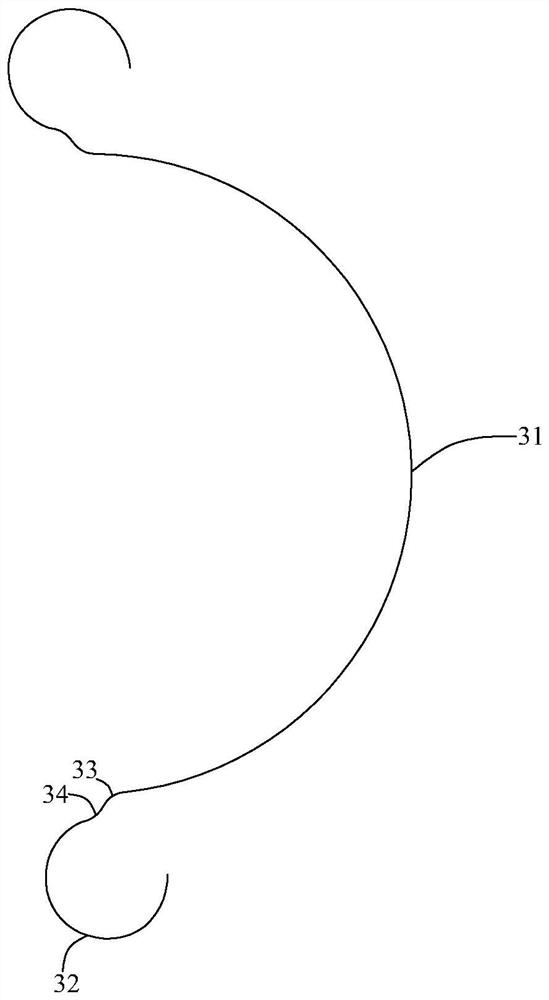

Embodiment 3

[0048] see Image 6 , a kind of airless tire is also disclosed in this embodiment 3, and the difference with embodiment 2 is: these three parts of inner hub 2, outer rim 4 and spoke plate 3 are all made of the composite material in embodiment 1, Moreover, during production and processing, the three parts are integrally formed by pouring, so the two ends of the spoke plate 3 do not need to be provided with the hook structure described in embodiment 2. In this embodiment 3, the spoke plate 3 is arc-shaped, " Any one of 3" font or S shape is acceptable.

[0049] In this embodiment 3, the integrated tire body supporting part used to support the tire tread made of the inner hub 2, the outer rim 4 and the spoke plate 3 has greatly improved performance, including cushioning performance, mechanical Strength, impact resistance, toughness and weight are all better than existing airless tires.

[0050] In present embodiment 3, the assembly method of airless tire is:

[0051] Firstly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com