Optical fiber surface enhanced raman probe based on surface plasmon effect and manufacturing method thereof

A surface plasmon, surface-enhanced Raman technology, applied in Raman scattering, material excitation analysis, material analysis by optical means, etc., can solve problems such as background interference, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. Following examples are only used to more clearly illustrate technical scheme of the present invention, and can not limit protection scope of the present invention with this.

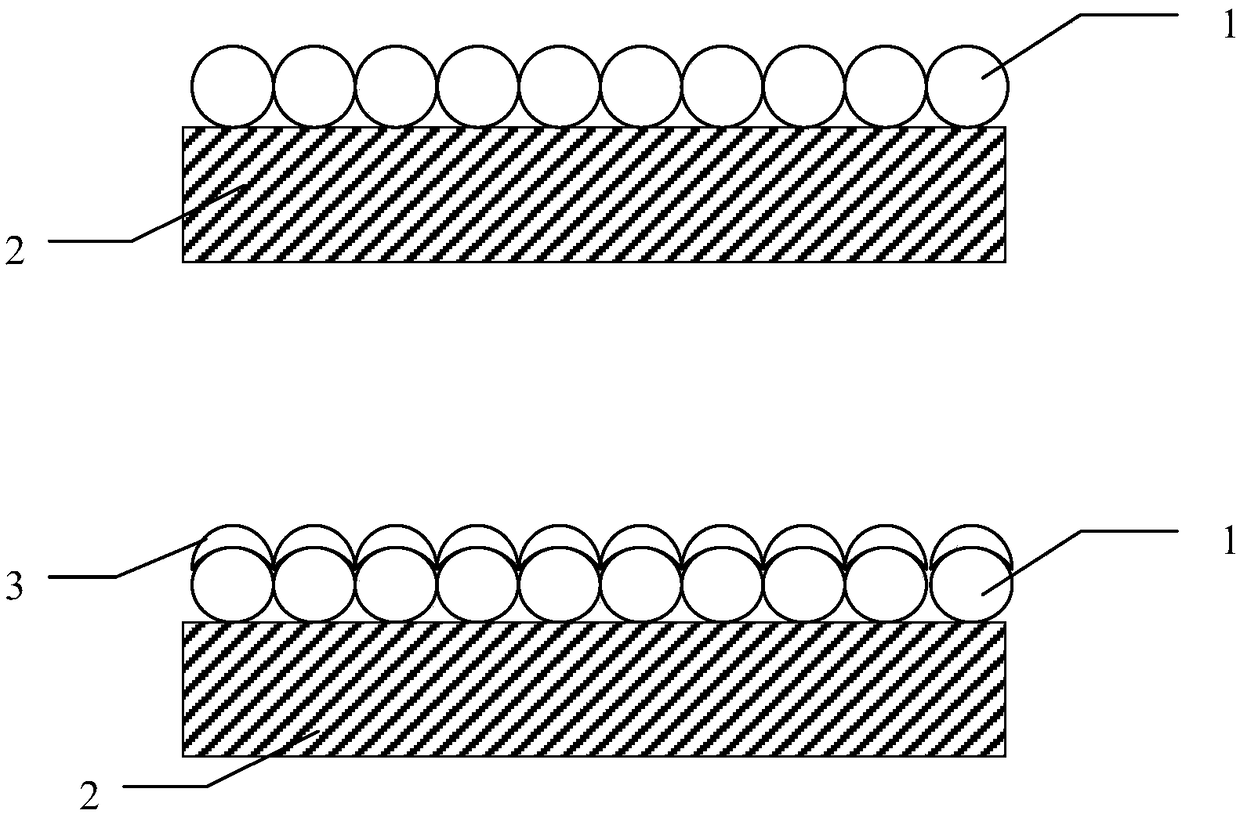

[0026] Such as figure 1 As shown, it is a schematic diagram of the SERS substrate, including a quartz substrate 2, on which a polystyrene (PS) nanoscale microsphere array is arranged, and the top of the PS microsphere array 1 is also covered with a metallic silver film 3 , forming a hemispherical metallic silver array, and the microsphere array may have certain defects.

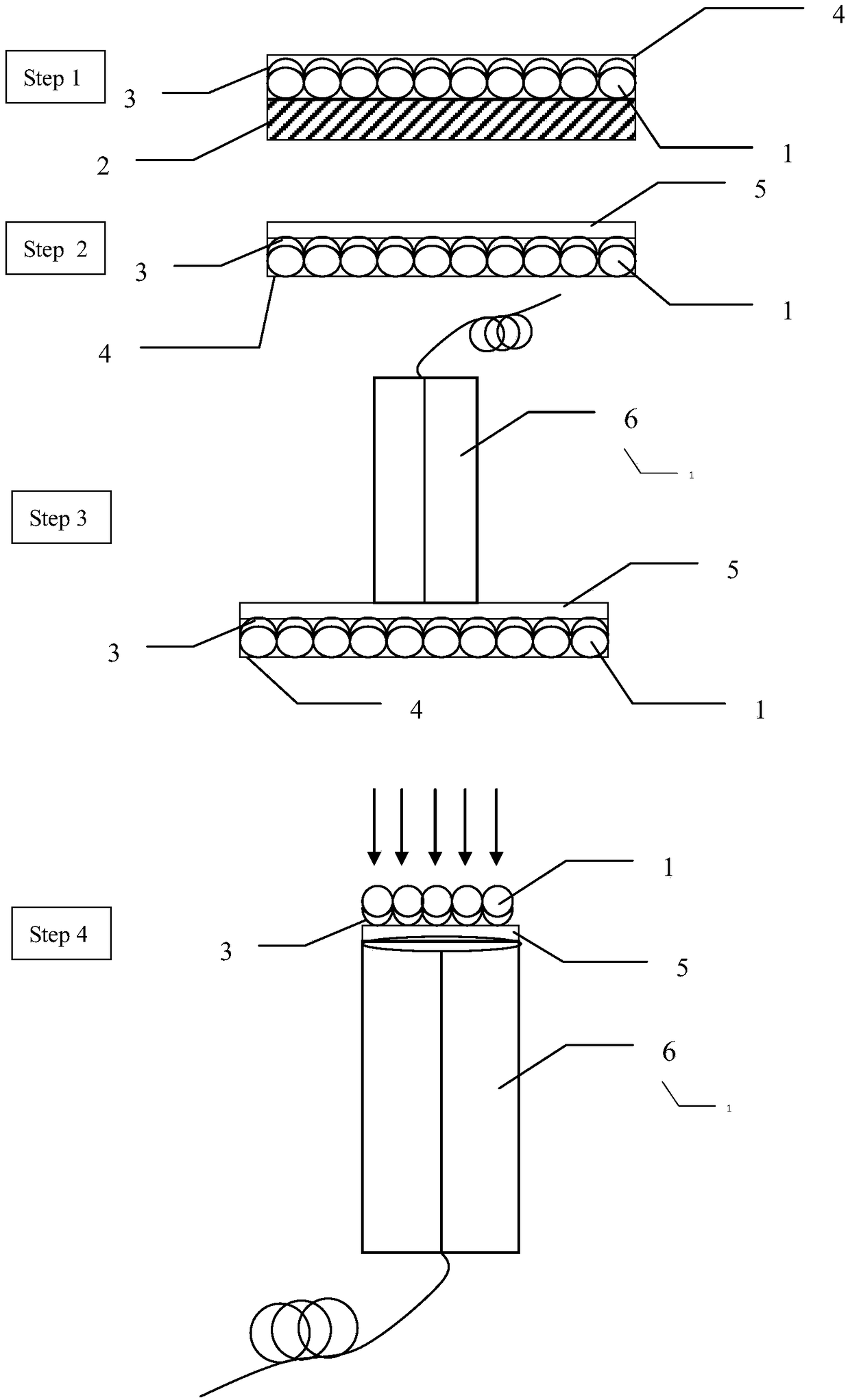

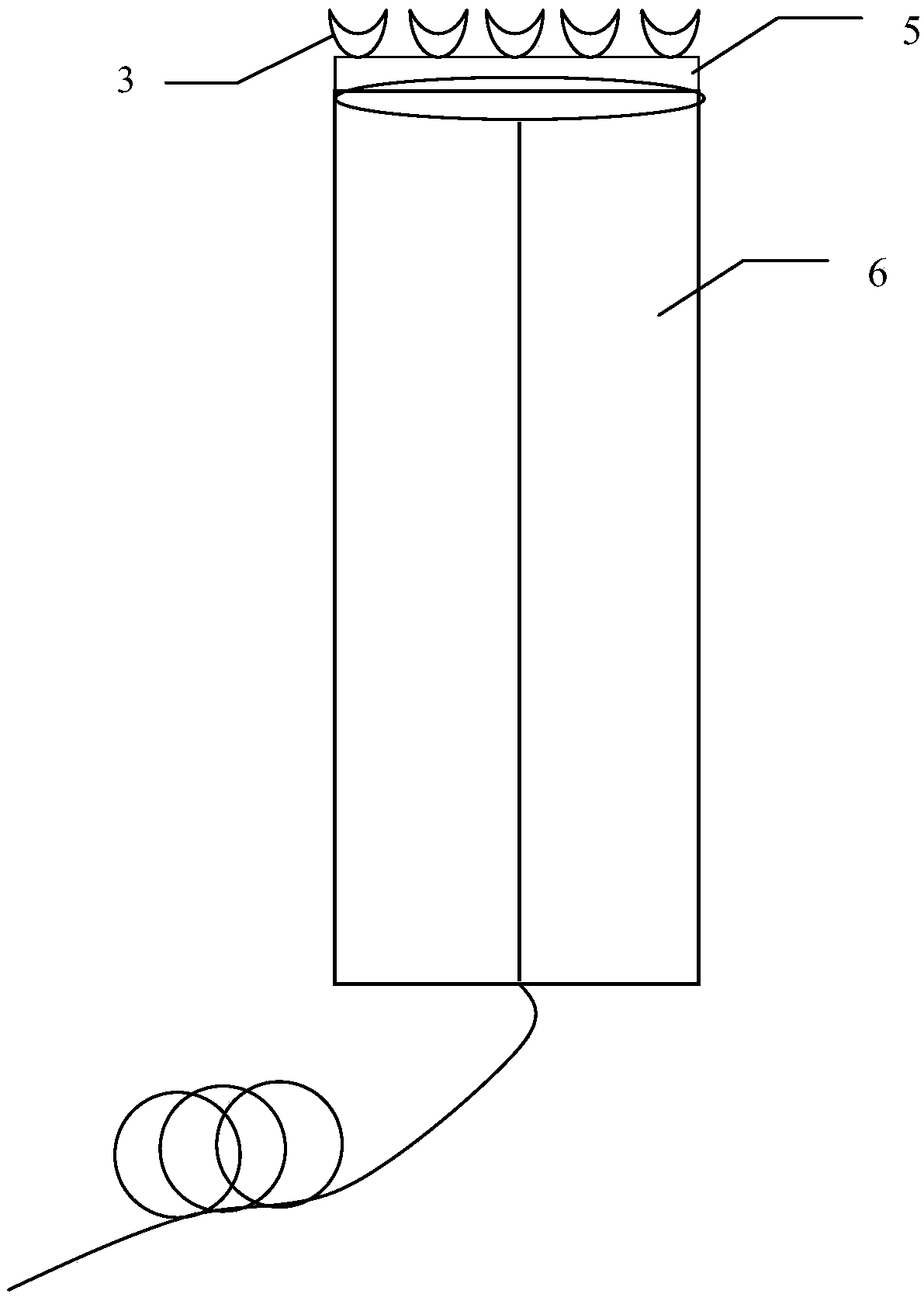

[0027] The flow chart of the present invention is as figure 2 As shown, the PMMA photoresist 4 is evenly filled between the PS microsphere arrays 1, and the Noa glue 5 is coated on the surface of the PMMA photoresist 4, after the film of the quartz substrate 2 is removed and transferred to the optical fiber This structure can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com