Porous dickite coated non-woven lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and dickite technology, which is applied in the field of power-type lithium-ion battery separators and their preparation, can solve the problems of unfavorable battery internal resistance, reduction of battery high-current charge and discharge, insufficient liquid absorption, low porosity, etc. The effect of improving cycle stability, improving electrical conductivity, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

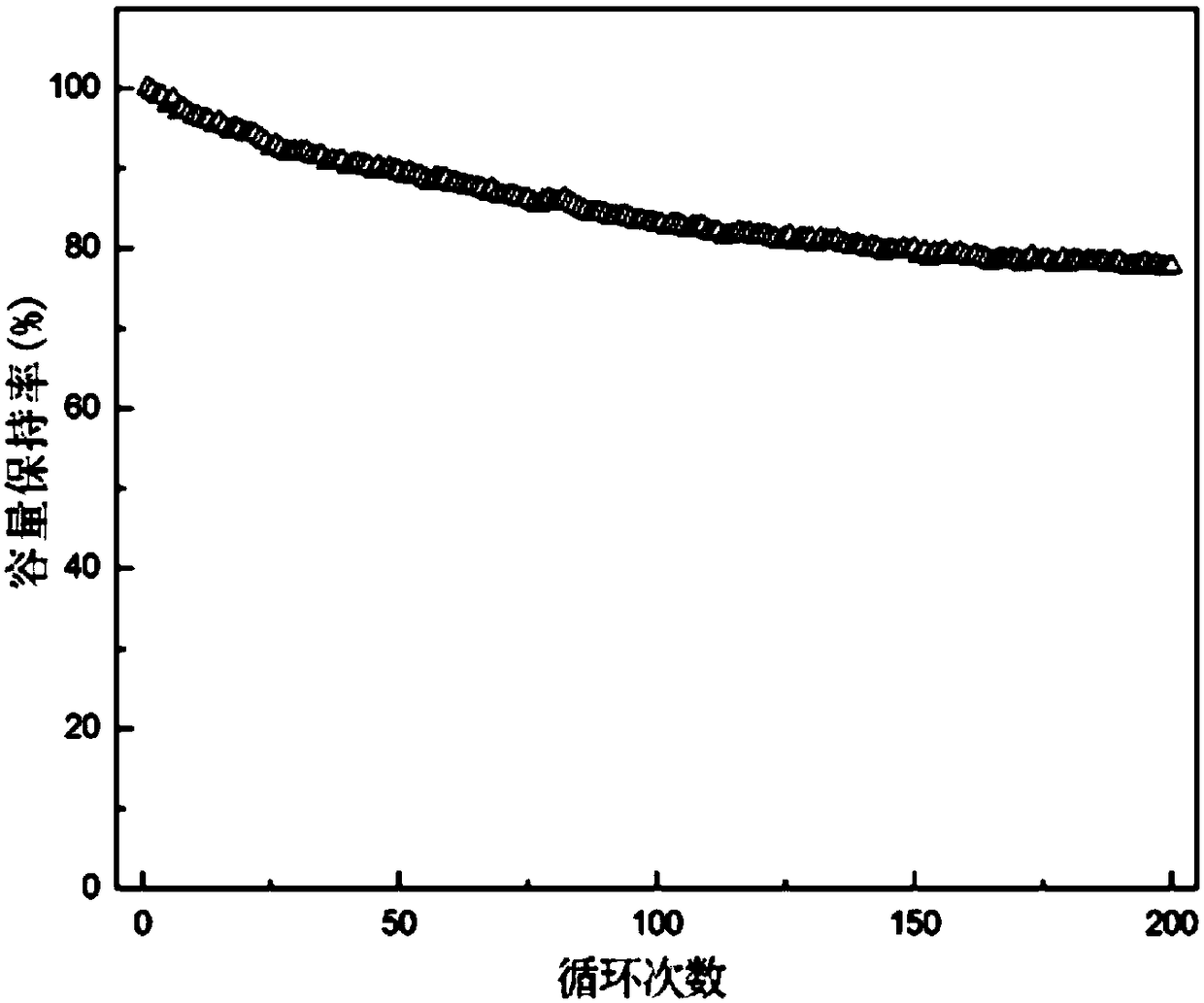

Image

Examples

preparation example Construction

[0019] a. Preparation of porous dickite

[0020] Dickite and a certain proportion of urea are pulverized in a pulverizer for 5 to 20 minutes, so that the particle size is less than 270 mesh, and the mass of urea is 10 to 25 wt% of the dickite mass. The mixture is placed in an open glass container and placed in a microwave oven. Heat it on medium-high heat for 10-20 minutes, and then put it in an oven at 70°C for 50 hours. Then mix and grind the mixture with potassium chlorate for 40 minutes, the consumption of potassium chlorate is 4% of dickite mass. Finally, the mixture mixed with potassium chlorate was put into an electric furnace at 550° C. for 15 seconds and calcined to obtain a porous stone powder.

[0021] b. Preparation of Porous Dictite / PET Separator

[0022] After uniformly mixing porous ground stone with binder, water, and modifier in a mass ratio of 60-80:33-13:5:2, the coating slurry is obtained by stirring in a homogenizer for 1-2 hours , and then immerse the ...

Embodiment 1

[0024] a. dickite and a certain proportion of urea are pulverized in a pulverizer for 10 minutes, so that the particle size is less than 270 mesh, and the quality of urea is 10wt% of the dickite quality;

[0025] b. Put the mixture in an open glass container, heat it in a microwave oven for 17 minutes, and then put it in an oven at 70°C for 50 hours;

[0026] c. the mixture was mixed with potassium chlorate and ground for 40 minutes, and the consumption of potassium chlorate was 4% of dickite quality;

[0027] d. Put the mixture mixed with potassium chlorate into an electric furnace at 550°C for 15 seconds and calcinate to obtain porous ground stone powder;

[0028] e. After uniformly mixing porous ground stone with binder, water, and modifier in a mass ratio of 80:13:5:2, stir in a homogenizer for 1 hour to obtain a coating slurry;

[0029] f. Immerse the PET non-woven fabric in the coating slurry for 30 minutes, then take it out and dry it in a vacuum oven at 40° C. to obta...

Embodiment 2

[0032] a. dickite and a certain proportion of urea were pulverized in a pulverizer for 15 minutes, so that the particle size was less than 270 mesh, and the quality of urea was 15wt% of the dickite quality;

[0033] b. Put the mixture in an open glass container, heat it in a microwave oven for 15 minutes, and then put it in an oven at 70°C for 50 hours;

[0034] c. the mixture was mixed with potassium chlorate and ground for 40 minutes, and the consumption of potassium chlorate was 4% of dickite quality;

[0035] d. Put the mixture mixed with potassium chlorate into an electric furnace at 550°C for 15 seconds and calcinate to obtain porous ground stone powder;

[0036] e. After uniformly mixing porous ground stone with binder, water, and modifier in a mass ratio of 70:23:5:2, stir in a homogenizer for 2 hours to obtain a coating slurry;

[0037] f. Immerse the PET non-woven fabric in the coating slurry for 30 minutes, then take it out and dry it in a vacuum oven at 40° C. to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com