Starch octenyl succinate-zein complex and preparation method thereof

A technology of zein and octenyl succinic acid, which is applied in the field of food processing, can solve the problems of rare research on the characteristics of SSOS-zein complexes, and achieve the effects of being beneficial to industrial production, simple equipment and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

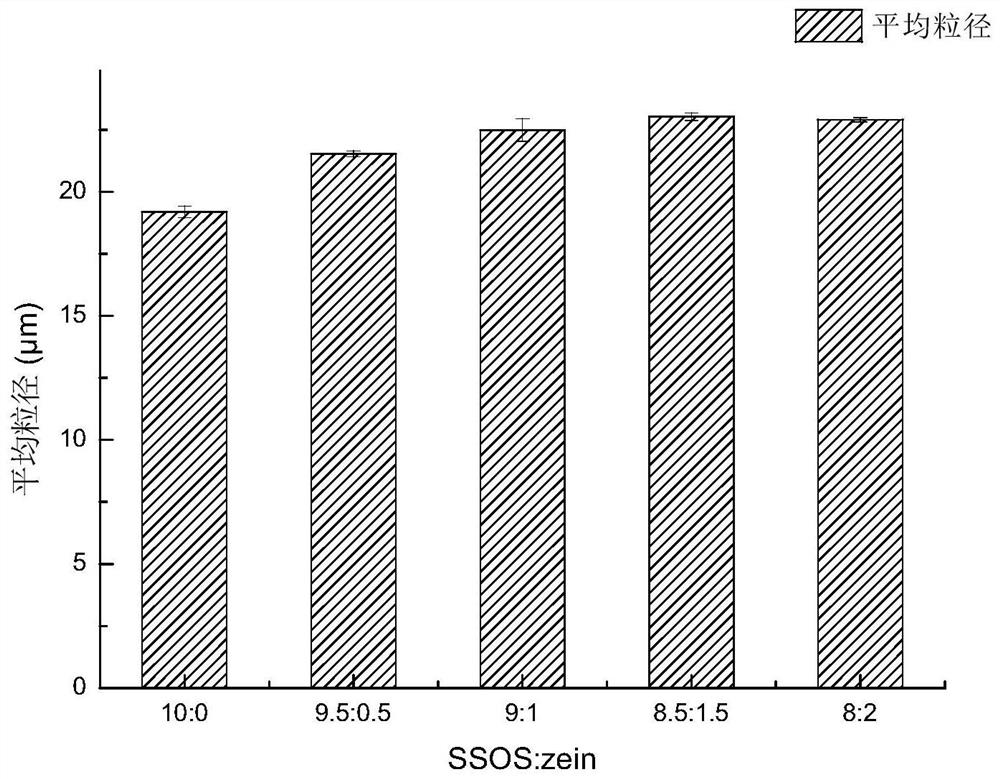

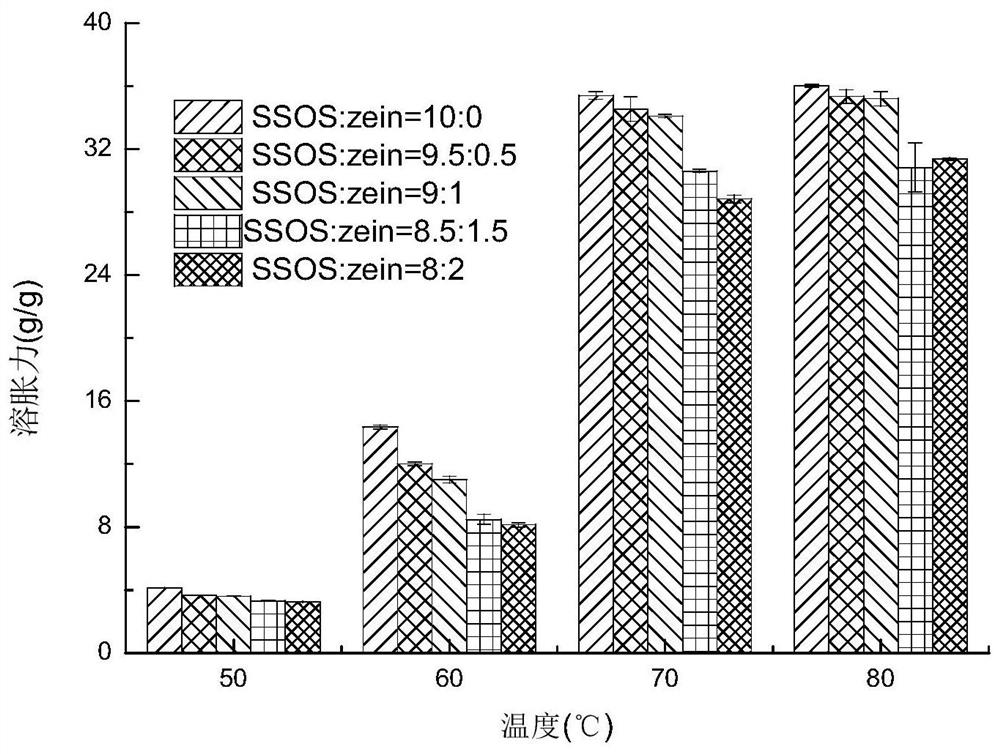

[0039] A kind of preparation method of octenyl starch succinate-zein complex, comprises the following steps:

[0040] (1) Mix starch octenyl succinate with 80% (v / v) ethanol solution to make starch milk with a solid-liquid ratio of 1:10 (g / mL), and gelatinize in a constant temperature water bath at 85°C for 15 minutes;

[0041] (2) dissolving zein in 80% (v / v) ethanol solution to make a zein solution with a concentration of 100 g / L;

[0042] (3) Mix gelatinized starch milk and zein solution according to the weight ratio of starch octenyl succinate: zein 9.5:0.5, adjust the pH to 7, react in a constant temperature water bath at 40°C for 30 minutes, Rotary steaming, suction filtration, drying at 45°C, and passing through a 100-mesh sieve.

Embodiment 2

[0044] A kind of preparation method of octenyl starch succinate-zein complex, comprises the following steps:

[0045] (1) Mix starch octenyl succinate with 80% (v / v) ethanol solution to make starch milk with a solid-liquid ratio of 1:10 (g / mL), and gelatinize in a constant temperature water bath at 85°C for 15 minutes;

[0046] (2) dissolving zein in 80% (v / v) ethanol solution to make a zein solution with a concentration of 100 g / L;

[0047] (3) Mix gelatinized starch milk and zein solution according to the weight ratio of starch octenyl succinate: zein 9:1, adjust the pH to 7, and react in a constant temperature water bath at 40°C for 30 minutes, Rotary steaming, suction filtration, drying at 45°C, and passing through a 100-mesh sieve.

Embodiment 3

[0049] A kind of preparation method of octenyl starch succinate-zein complex, comprises the following steps:

[0050] (1) Mix starch octenyl succinate with 80% (v / v) ethanol solution to make starch milk with a solid-liquid ratio of 1:10 (g / mL), and gelatinize in a constant temperature water bath at 85°C for 15 minutes;

[0051] (2) dissolving zein in 80% (v / v) ethanol solution to make a zein solution with a concentration of 100 g / L;

[0052] (3) Mix gelatinized starch milk and zein solution according to the weight ratio of starch octenyl succinate: zein 8.5:1.5, adjust the pH to 7, react in a constant temperature water bath at 40°C for 30 minutes, Rotary steaming, suction filtration, drying at 45°C, and passing through a 100-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com