Dexibuprofen liposome as well as preparation method and application thereof

A technology of liposomes and plastids, which is applied in the field of biomedicine, can solve the problem of easy crystallization and precipitation of Dexibuprofen emulsion or gel, reduce the stability of Dexibuprofen topical preparations, and the solubility of Dexibuprofen Low-level problems, to achieve the effect of increasing skin penetration, promoting penetration through the stratum corneum, and increasing skin retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

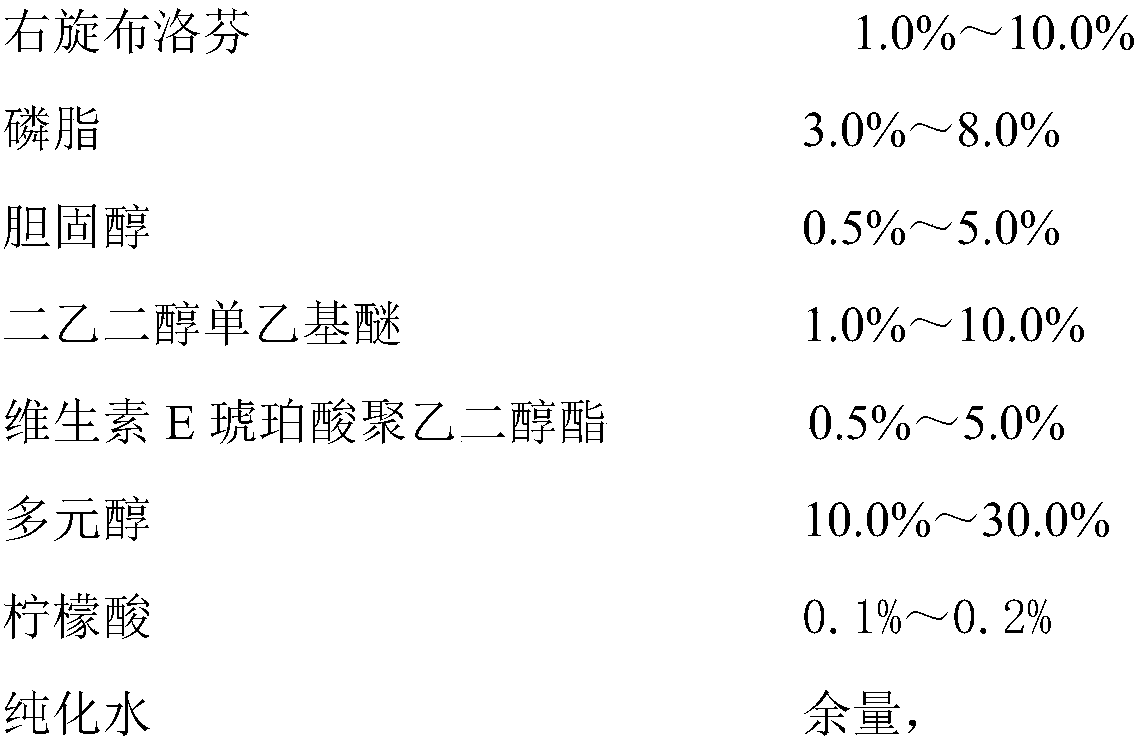

Method used

Image

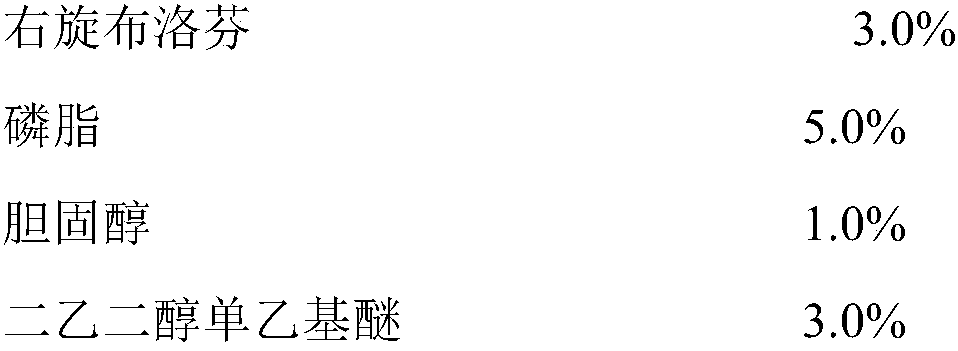

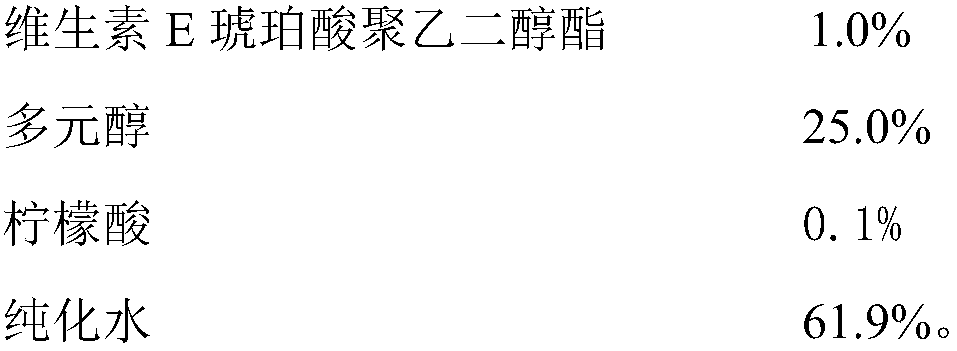

Examples

Embodiment 1

[0032] (1) Prepare the oil phase: melt 3.0% dipalmitoylphosphatidylglycerol, 1% dipalmitoylphosphatidylethanolamine, 0.5% cholesterol, and 1.0% diethylene glycol monoethyl ether in a 65°C water bath. Then add 1.0% Dexibuprofen, mix well, and set aside;

[0033] (2) Prepare the water phase: add 0.5% vitamin E polyethylene glycol succinate, 5.0% polyethylene glycol 400, 5.0% glycerin, and 0.2% citric acid into 83.8% water, stir and dissolve in a 65°C water bath;

[0034] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2) and keep stirring, then emulsify at 4000rpm high-speed shear for 10min to make a micron-scale dispersion;

[0035](4) Preparation of liposomes: heat the nano-dispersion prepared in step (3) at 45° C., and then circulate through high-pressure homogenization at 500 bar for 5 times to obtain ibuprofen liposomes. The particle diameter of the ibuprofen liposome is 140nm, and the encapsulation...

Embodiment 2

[0037] (1) Prepare the oil phase: melt 3.0% dipalmitoylphosphatidylglycerol, 2% dipalmitoylphosphatidylethanolamine, 3.0% cholesterol, and 6.0% diethylene glycol monoethyl ether in a water bath at 85°C. Then add 5.0% Dexibuprofen, mix well, and set aside;

[0038] (2) Prepare the water phase: add 2.0% vitamin E polyethylene glycol succinate, 8.0% polyethylene glycol 400, 10.0% glycerin, and 0.18% citric acid into 60.82% water, stir and dissolve in a water bath at 85°C;

[0039] (3) Preparation of micron-scale dispersion: drop the oil phase prepared in step (1) into the water phase prepared in step (2) and keep stirring, then emulsify at 6000rpm high-speed shear for 5min to make a micron-scale dispersion;

[0040] (4) Preparation of liposomes: the nano-dispersion prepared in step (3) was incubated at 70° C., and then circulated 3 times through high-pressure homogenization at 800 bar to obtain Dexibuprofen liposomes. The particle diameter of the ibuprofen liposome is 171nm, and...

Embodiment 3

[0042] (1) Prepare the oil phase: melt 4.0% dipalmitoylphosphatidylglycerol, 4% dipalmitoylphosphatidylethanolamine, 10.0% diethylene glycol monoethyl ether, and 5.0% cholesterol in a 70°C water bath; Then add 10.0% Dexibuprofen, mix well, and set aside;

[0043] (2) Prepare the water phase: add 3.0% vitamin E polyethylene glycol succinate, 7.0% polyethylene glycol 400, 14.0% glycerin, and 0.15% citric acid to 42.85% water, stir and dissolve in a 70°C water bath;

[0044] (3) Preparation of micron-scale dispersion: add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2) and stir continuously, and then emulsify at 1000rpm high-speed shear for 1min to prepare a micron-scale dispersion;

[0045] (4) Preparation of liposomes: heat the nano-dispersion prepared in step (3) at 50° C., and then circulate 8 times through high-pressure homogenization at 1500 bar to obtain Dexibuprofen liposomes. The particle diameter of the ibuprofen liposome is 178nm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com