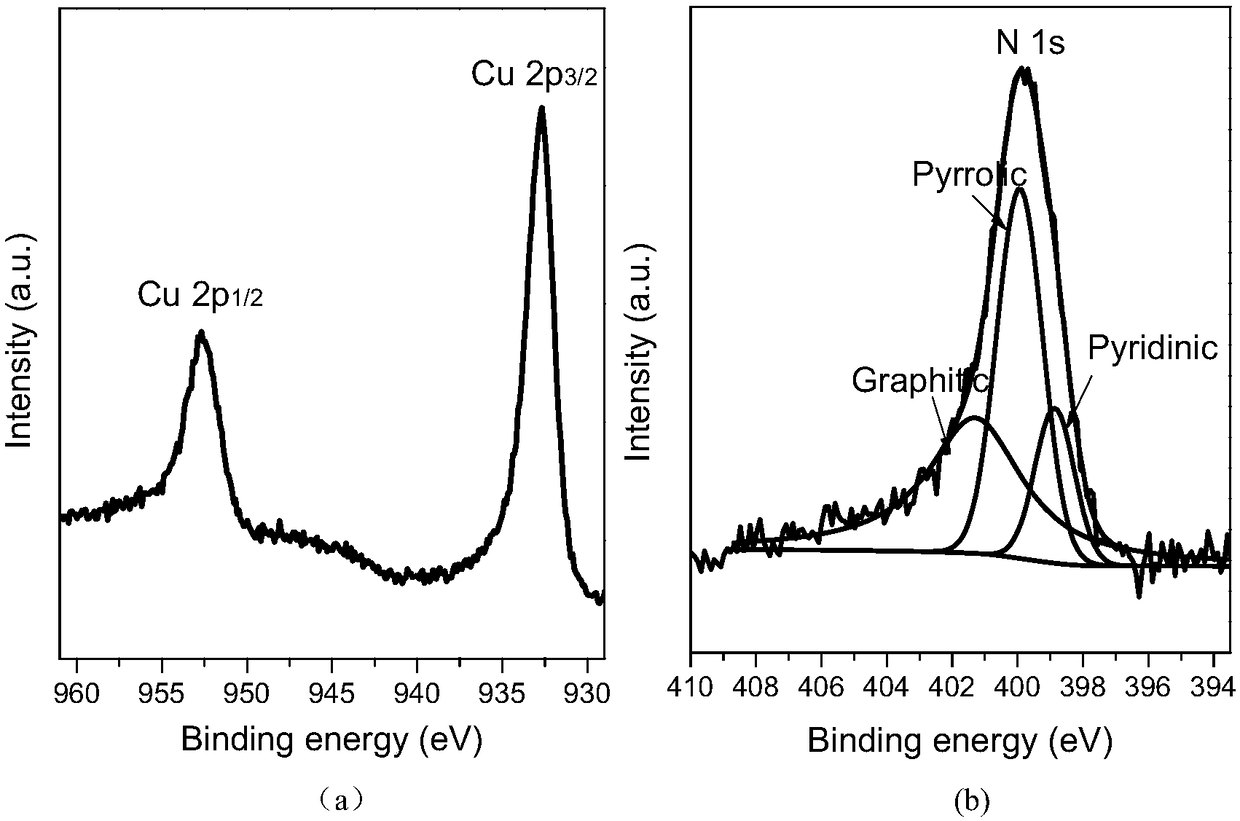

Copper-nitrogen co-doped carbon nanotube catalyst and preparation method and application thereof

A carbon nanotube and co-doping technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. High reducing activity, easy to control, easy to control the effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Take a certain amount of commercial carbon nanotubes with a diameter of 10-20nm, in 30% HNO 3 Reflux at 80°C for 3 hours, rinse with deionized water until neutral after cooling, and dry. Dissolve the dried carbon nanotubes in 0.01mol / L Cu(NO 3 ) 2 In the aqueous solution, the mass ratio of copper to carbon nanotubes is 1:100. Add 0.01mol / L citric acid, place it on a magnetic stirrer and stir continuously, and slowly add NaOH solution during the stirring process to adjust the pH of the solution to neutral. The suspension obtained by the above stirring was ultrasonically dispersed at 5°C for 2 hours, continued to stir for 24 hours, and then was taken out and dried. The obtained powder was roasted in nitrogen, the gas flow rate of the nitrogen atmosphere was 100mL / min, the temperature was raised from room temperature to 350°C at a rate of 10°C / min, and the temperature was kept for 5h. After cooling down to room temperature, pass H 2 atmosphere for reduction, H 2 The ...

Embodiment 2

[0056] Take a certain amount of commercial carbon nanotubes with a diameter of 10-20nm, in 30% HNO 3 Reflux at 80°C for 3 hours, rinse with deionized water until neutral after cooling, and dry. Dissolve the dried carbon nanotubes in 0.01mol / L Cu(NO 3 ) 2 In the aqueous solution, the mass ratio of copper to carbon nanotubes is 1:50. Add 0.01mol / L sodium citrate, place it on a magnetic stirrer and stir continuously, and slowly add NaOH solution during the stirring process to adjust the pH of the solution to neutral. The suspension obtained by the above stirring was ultrasonically dispersed at 5°C for 2 hours, continued to stir for 24 hours, and then was taken out and dried. The obtained powder was roasted in nitrogen, the gas flow rate of the nitrogen atmosphere was 100mL / min, the temperature was raised from room temperature to 350°C at a rate of 10°C / min, and the temperature was kept for 5h. After cooling down to room temperature, pass H 2 atmosphere for reduction, H 2 Th...

Embodiment 3

[0058] Take a certain amount of commercial carbon nanotubes with a diameter of 10-20nm, in 30% HNO 3 Reflux at 80°C for 3 hours, rinse with deionized water until neutral after cooling, and dry. Dissolve the dried carbon nanotubes in 0.01mol / L Cu(NO 3 ) 2 In the aqueous solution, the mass ratio of copper to carbon nanotubes is 1:20. Add 0.01mol / L citric acid, place it on a magnetic stirrer and stir continuously, and slowly add NaOH solution during the stirring process to adjust the pH of the solution to neutral. The suspension obtained by the above stirring was ultrasonically dispersed at 5° C. for 2 h, continued stirring for 24 h, and then taken out and dried. The obtained powder was roasted in nitrogen, the gas flow rate of the nitrogen atmosphere was 100mL / min, the temperature was raised from room temperature to 350°C at a rate of 10°C / min, and the temperature was kept for 5h. After cooling down to room temperature, pass H 2 atmosphere for reduction, H 2 The gas flow r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com