A low-temperature curing agent for concrete

A low-temperature curing and concrete technology, applied in the field of building materials, can solve problems such as difficulty in control, decrease in concrete strength, and large strength loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, commonly used early-strength agents in the market are AFA concrete super-early-strength agents from Henan Aluminum City Juneng Industrial Co., Ltd., DC early-strength agents from Beijing Dechang Weiye Construction Engineering Technology Co., Ltd., and Suzhou Longlong Chemical Technology Co., Ltd. Calcium formate is mixed by external mixing method. First, the early strength agent is mixed into the cementitious material and mixed evenly, and then water and sand are added to stir and form. The water-cement ratio of the prepared mortar is 0.45, and the ratio of mortar to sand is 1:3. Immediately after forming the mortar, put it into a low-temperature curing box at 5±1°C and a standard curing box at 20±1°C for curing until the specified age and then take it out. Test for compressive strength. Under this example, the strength test results are shown in Table 1 below. Mixing several kinds of early strength agents respectively, compared with the mortar without ...

Embodiment 2

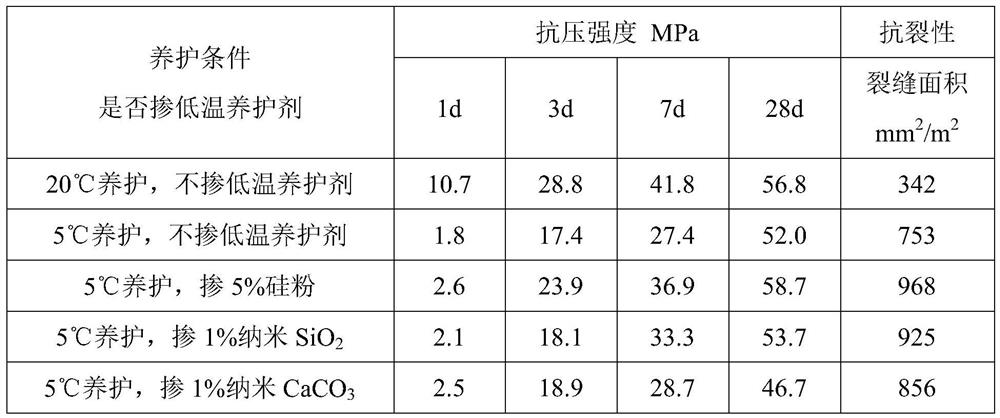

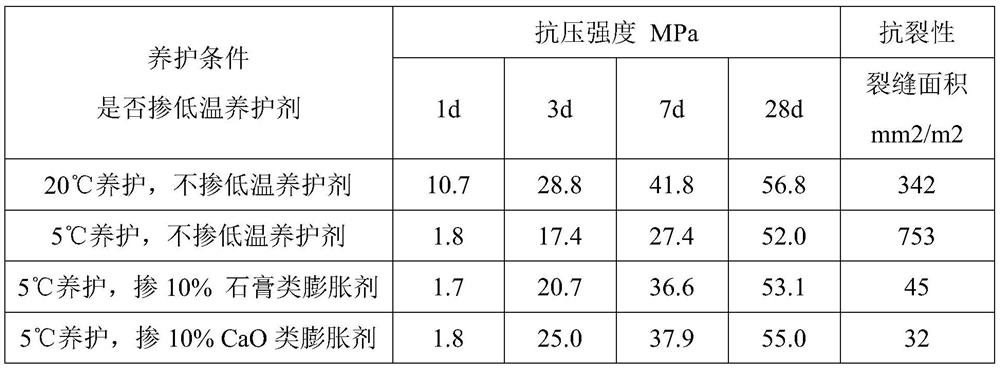

[0026] This embodiment uses crystal nucleus materials alone, including silicon powder, nano-SiO 2 , Nano CaCO 3 etc., using the external mixing method to mix, first mix the crystal nucleus material into the cementitious material and dry mix it evenly, then add water and sand and mix it into shape. The water-cement ratio of the prepared mortar is 0.45, and the ratio of mortar to sand is 1:3. Immediately after forming the mortar, put it into a low-temperature curing box at 5±1°C and a standard curing box at 20±1°C for curing until the specified age and then take it out. Test for compressive strength. Under this example, the strength test results are shown in Table 2 below. After the crystal nucleus material is added, the strength of the mortar for 1-3 days is also significantly improved, and the improvement range is slightly lower than that of ordinary early strength agents, and it cannot be compared with the mortar strength under the standard curing condition of 20°C; the cry...

Embodiment 5

[0027] Table 2 Embodiment 5 Effect

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com