Nanometer anti-channeling agent and preparation method thereof, and anti-channeling cement paste

A technology of anti-channeling agent and cement slurry, which is applied in the field of oil drilling, can solve the problems of fluctuating fluidity and thickening time, reducing the compressive strength of cement stone, and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

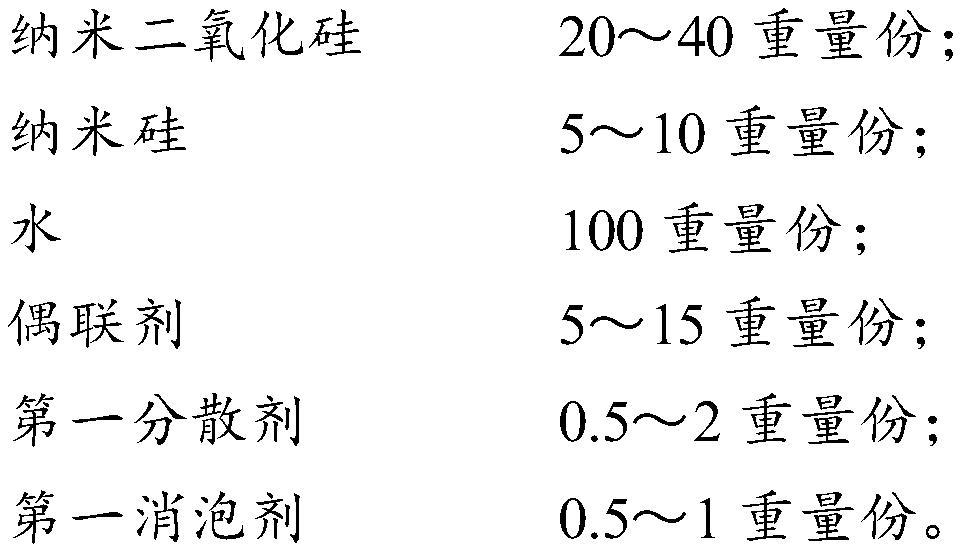

[0039] The present invention also provides a preparation method of the above-mentioned nano anti-channeling agent, comprising: S1) mixing and stirring water and the first dispersant, then adding nano silicon dioxide and nano silicon, dispersing and stirring to obtain a mixed slurry; S2) The mixed slurry, the coupling agent and the first defoaming agent are mixed and stirred to obtain the nano anti-channeling agent.

[0040] The present invention has no special restrictions on the source of all raw materials, which can be commercially available, wherein, the water, the first dispersant, nano-silica, nano-silicon, coupling agent and the first defoamer are the same as above , and will not be repeated here.

[0041] Mix and stir water and the first dispersant; the mixing and stirring speed is preferably 500 to 1500r / min, more preferably 800 to 1200r / min, and more preferably 1000r / min; the mixing and stirring time is preferably 5 to 1000r / min 15 minutes, more preferably 8-12 minut...

Embodiment 1

[0062] Take 100 parts by weight of distilled water, adjust the speed of the stirrer device to 1000r / min, add 0.5 parts by weight of sulfonated acetone formaldehyde condensate to the distilled water, stir at a constant speed for 10min; adjust the speed to 2000r / min, and then take 25 parts by weight of 150nm nano Silicon dioxide and 6 parts by weight of nano-silicon of 200nm are dispersed in the solution at this rotating speed, stirred for 15min until uniformly dispersed, and a mixed slurry is obtained; in the mixed slurry, 8 parts by weight of vinyltriethoxysilane are first added, Stir at a rotational speed of 2000r / min for 10min, then add 0.5 parts by weight of polyoxypropylene glyceryl ether, and stir at a rotational speed of 2000r / min for 10min to obtain the nano anti-channeling agent.

Embodiment 2

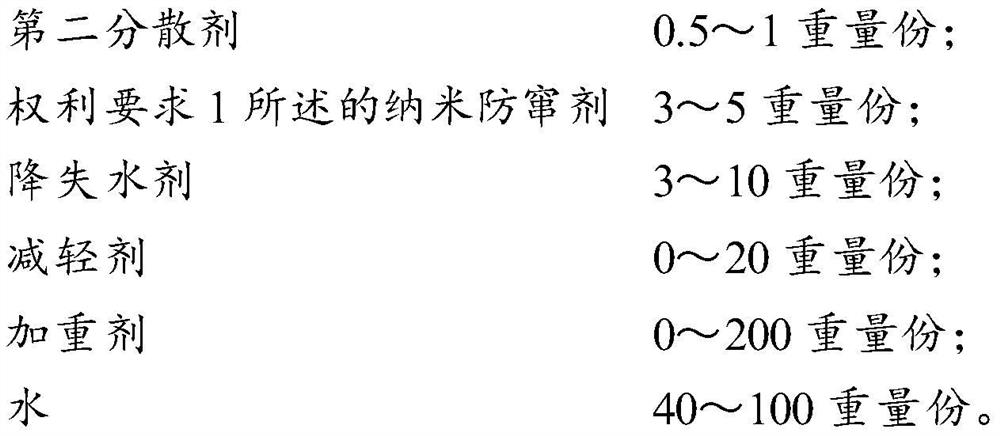

[0064] Anti-channeling cement slurry for extended reach wells, low density (1.50g / cm 3 ), which contains the following raw materials by weight: 100 parts by weight of Jiahua G grade cement, 0.5 parts by weight retarder (boric acid), 0.1 parts by weight of defoamer (polyoxypropylene glyceryl ether), 10 parts by weight of filler ( Fly ash particle diameter is 100 μm), 0.5 parts by weight dispersant (sulfonated acetone formaldehyde condensate), 5 parts by weight of anti-channeling agent (nano anti-channeling agent prepared in embodiment 1), 5 parts of fluid loss reducer (acrylamide -sodium acrylate copolymer), 20 parts by weight lightening agent (the particle size of the floating beads is 100 μm), 90 parts by weight of water. The raw materials are mixed and stirred evenly to prepare the anti-channeling cement slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com