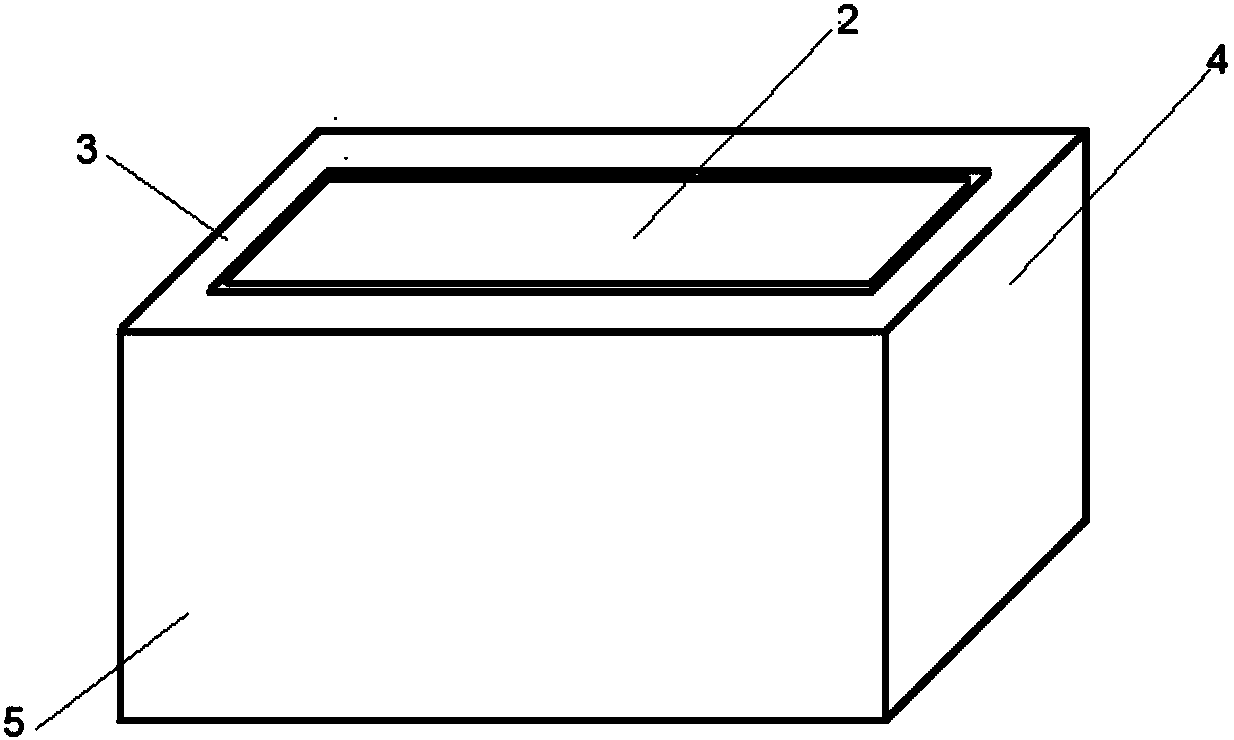

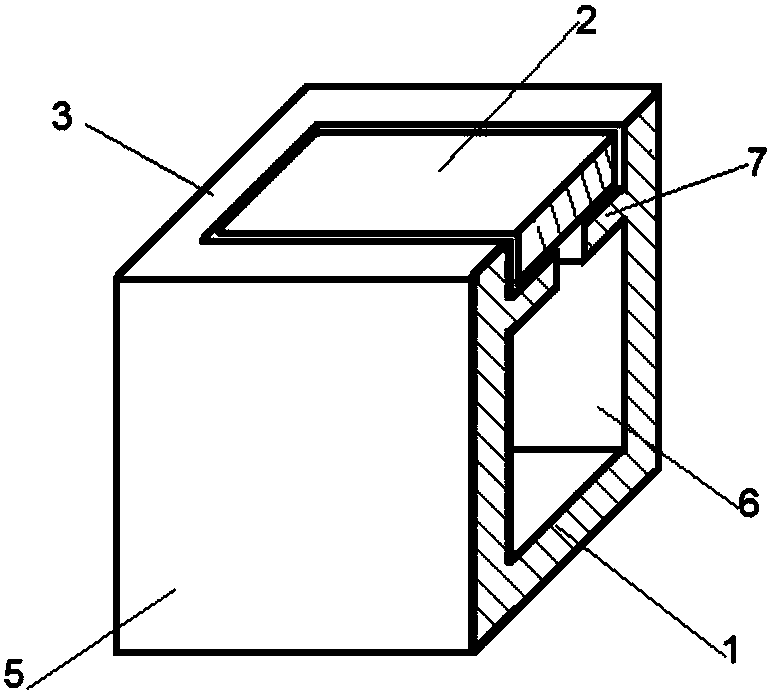

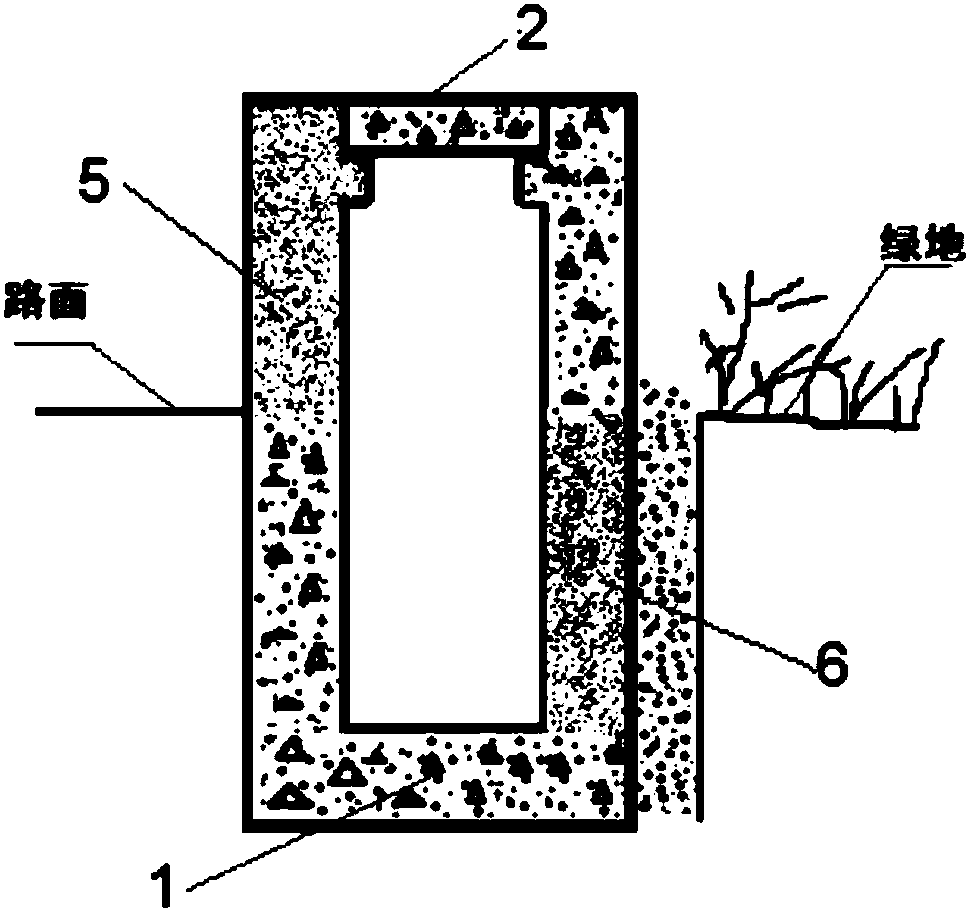

Cleanable water-permeable hollow kerb for receiving runoff

A curb, clean technology, applied in the direction of side ditch/curb, roads, roads, etc., can solve the problems of increasing maintenance cost, reducing groundwater level, waste, etc., to alleviate urban flood disasters, reduce maintenance costs, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The material with water-permeable function is made by the following method: 6-mesh quartz sand with a mass ratio of 0.7:0.2:0.05:0.1:0.02:0.04, ordinary Portland cement, silica fume, fly ash, calcium nitrate and pigment , water-cement ratio=0.3, polycarboxylate superplasticizer dosage is 4% of water, mix evenly, after pouring into the mold, smear sodium silicate aqueous solution with a mass concentration of 20% on the outer surface, penetrate to the inner surface, Drying; then apply a potassium carbonate aqueous solution with a mass concentration of 20%, penetrate to the inner surface, and then apply a layer of nano-titanium dioxide powder.

Embodiment 2

[0021] The material with water-permeable function is made by the following method: 4-mesh quartz sand with a mass ratio of 0.6:0.25:0.01:0.2:0.005:0.08, ordinary Portland cement, silica fume, fly ash, calcium nitrate and pigment , water-cement ratio=0.3, polycarboxylate superplasticizer dosage is 5% of water, mix evenly, after pouring into the mold, smear sodium silicate aqueous solution with a mass concentration of 2% on the outer surface, penetrate to the inner surface, Drying; then apply a potassium carbonate aqueous solution with a mass concentration of 2%, penetrate to the inner surface, and then apply a layer of nano-titanium dioxide powder.

Embodiment 3

[0023] The material with water permeability is made by the following method: 6-mesh quartz sand with a mass ratio of 0.8:0.1:0.1:0.05:0.04, ordinary Portland cement, silica fume, fly ash and calcium nitrate, the water-cement ratio =0.4, the dosage of polycarboxylate superplasticizer is 2% of water, mix evenly, after pouring into the mold, apply sodium silicate aqueous solution with a mass concentration of 40% on the outer surface, penetrate to the inner surface, and dry; then apply An aqueous solution of potassium carbonate with a mass concentration of 40% penetrates into the inner surface, and then a layer of nano-titanium dioxide powder is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com