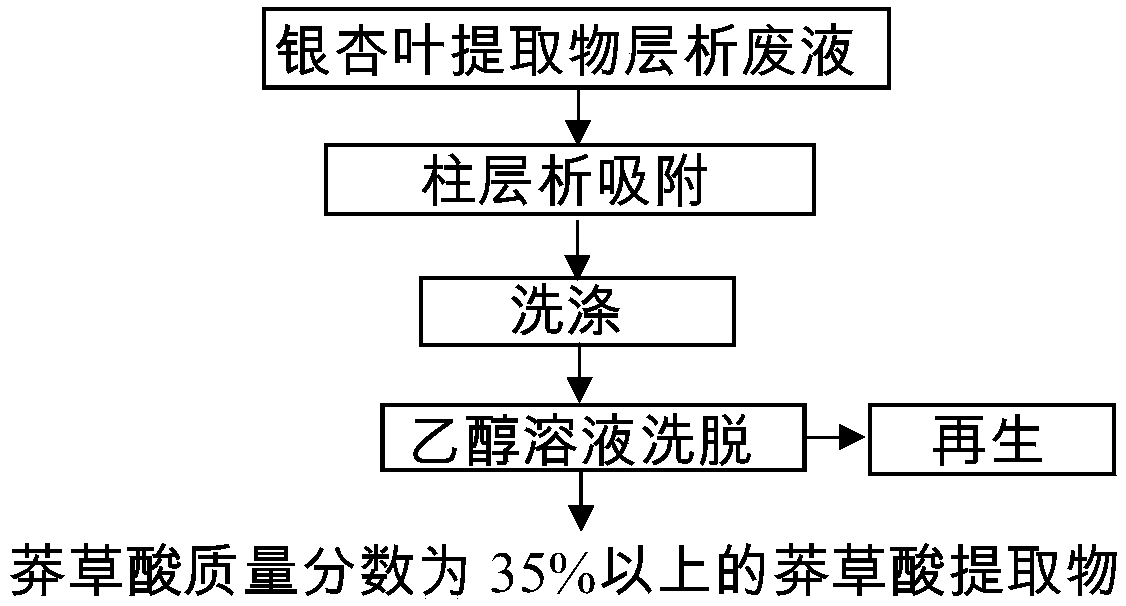

Method for preparing shikimic acid extract from folium ginkgo extract chromatography waste liquid

The technology of extract and ginkgo leaf, applied in the field of preparing shikimic acid extract, can solve the problems of unsuitability for ginkgo leaf extraction workshop, high cost of adsorbent, difficulty in scale, etc., and achieves good application value, low cost and large processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

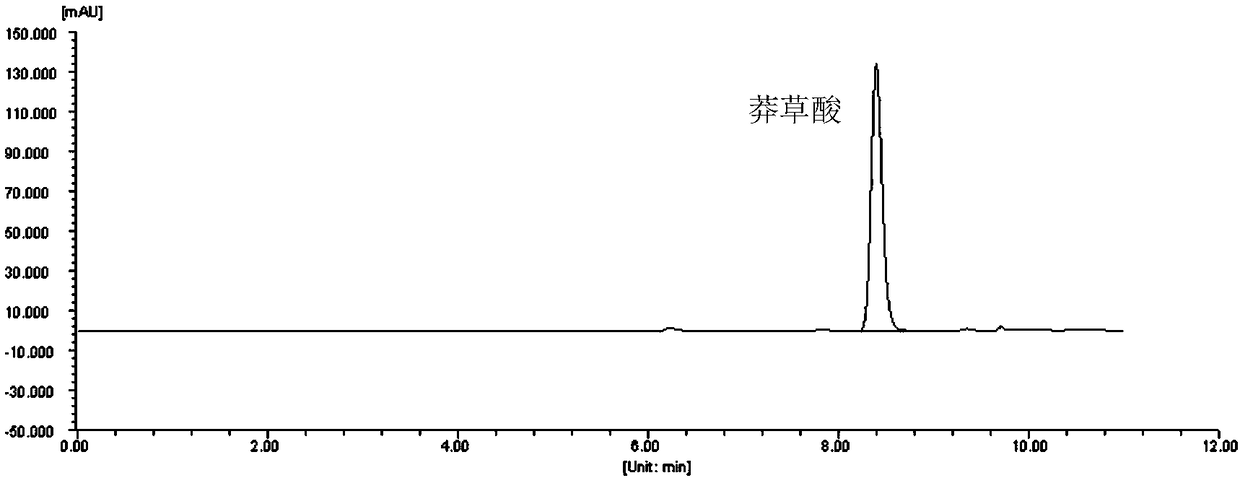

[0028] Pass the collected chromatographic washing liquid through the ADS21 type macroporous resin chromatography column at a flow rate of 0.5BV / h, and the ratio of the height to diameter of the chromatographic column is 9:1. The macroporous resin is rinsed at a flow rate of h, and then 4.0BV of 60% ethanol aqueous solution is used for eluting at a flow rate of 0.5BV / h, the eluate is collected, and the collected solution is concentrated and dried under reduced pressure to obtain final product. After HPLC analysis, the obtained Shikimic acid extract with a mass fraction of shikimic acid of 37.7%. The HPLC chart of the eluent is shown in image 3 shown.

Embodiment 2

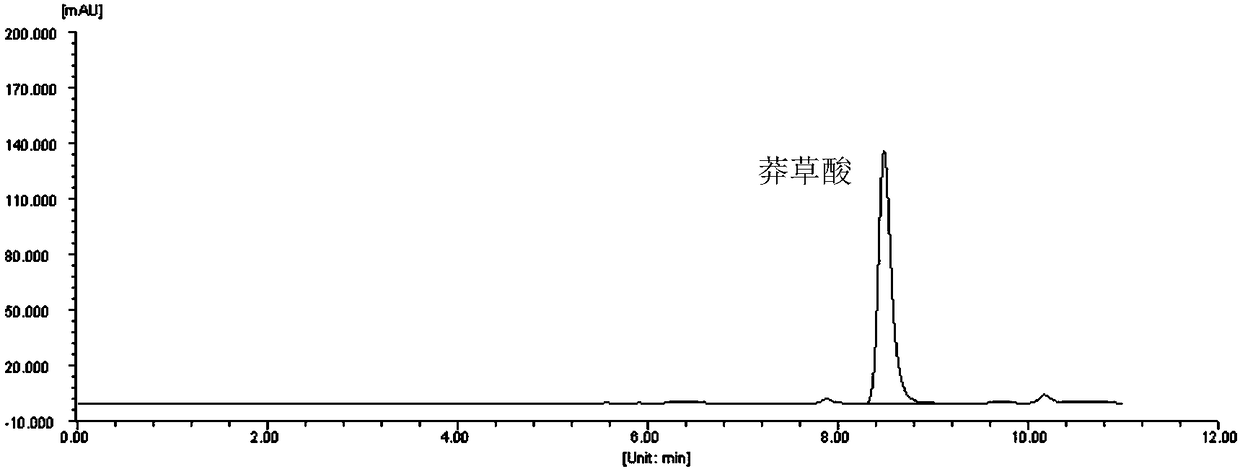

[0030] The collected chromatographic washing liquid is directly passed through the ADS21 type macroporous resin chromatographic column at a flow rate of 2.0BV / h, and the height-to-diameter ratio of the chromatographic column is 12:1. The macroporous resin was rinsed at a flow rate of 6.0BV / h, and then eluted with 40% ethanol aqueous solution of 6.0BV at a flow rate of 1.5BV / h, the eluate was collected, and the collected solution was concentrated and dried under reduced pressure to obtain final product. After HPLC analysis, A shikimic acid extract with a mass fraction of shikimic acid of 35.0% was obtained.

Embodiment 3

[0032] Pass the collected chromatographic flow-through directly through the NK109 macroporous resin chromatography column at a flow rate of 1.0BV / h. The column height-to-diameter ratio is 12:1. The macroporous resin is rinsed at a flow rate of BV / h, and then eluted with 6.0 BV of 10% ethanol aqueous solution at a flow rate of 2.0 BV / h, and the eluate is collected, and the collected liquid is concentrated and dried under reduced pressure, and analyzed by HPLC , to obtain a shikimic acid extract with a mass fraction of shikimic acid of 43.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com