Novel hydroxy acrylic acid dispersion and application thereof

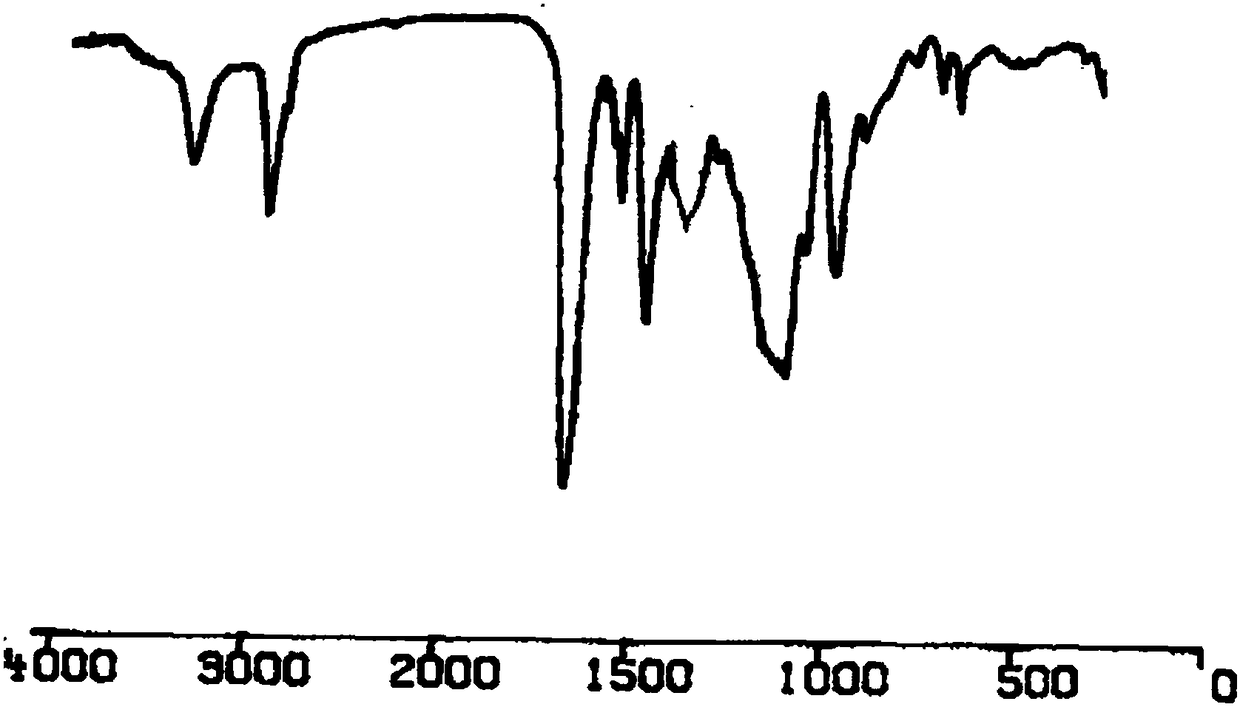

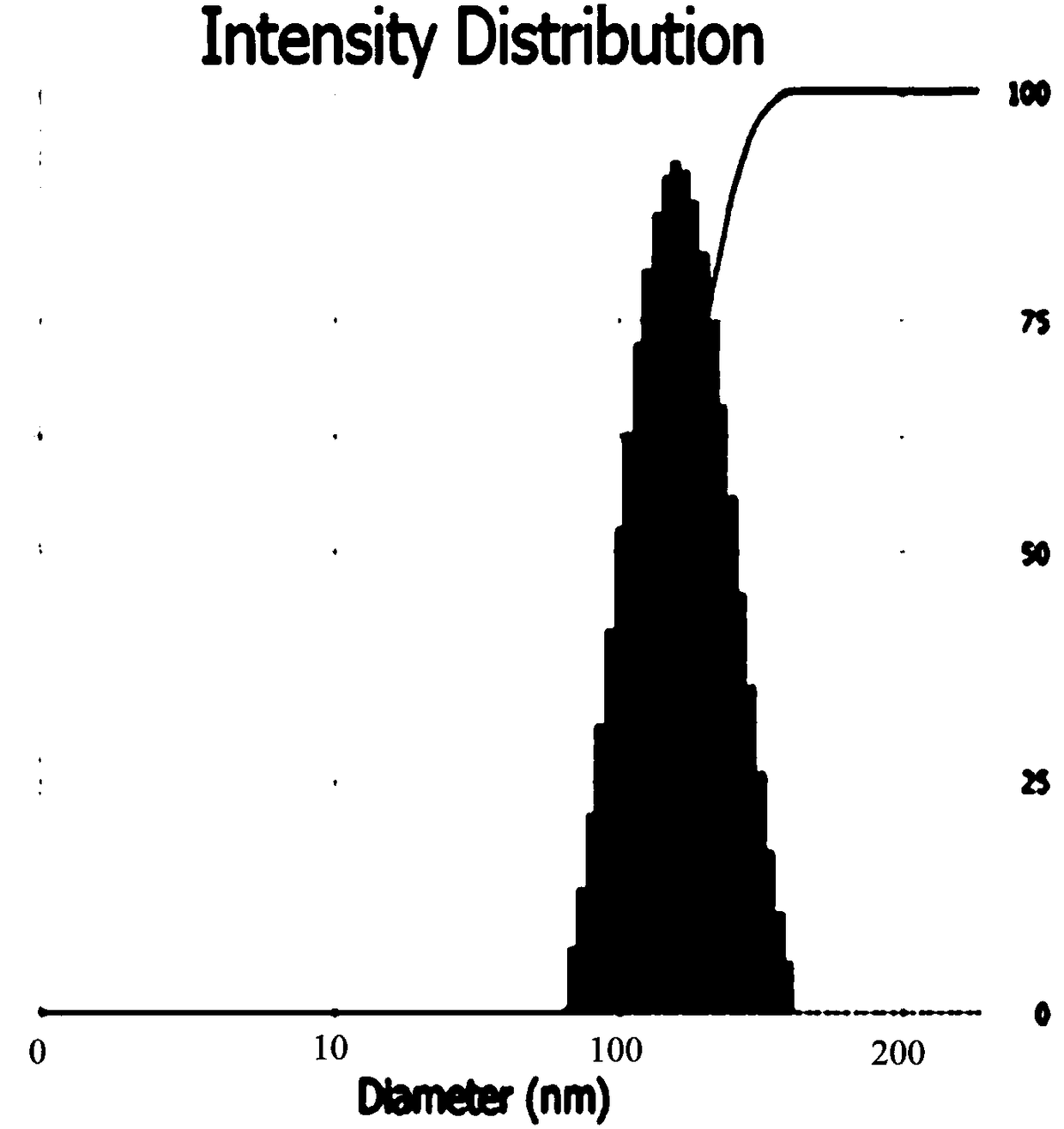

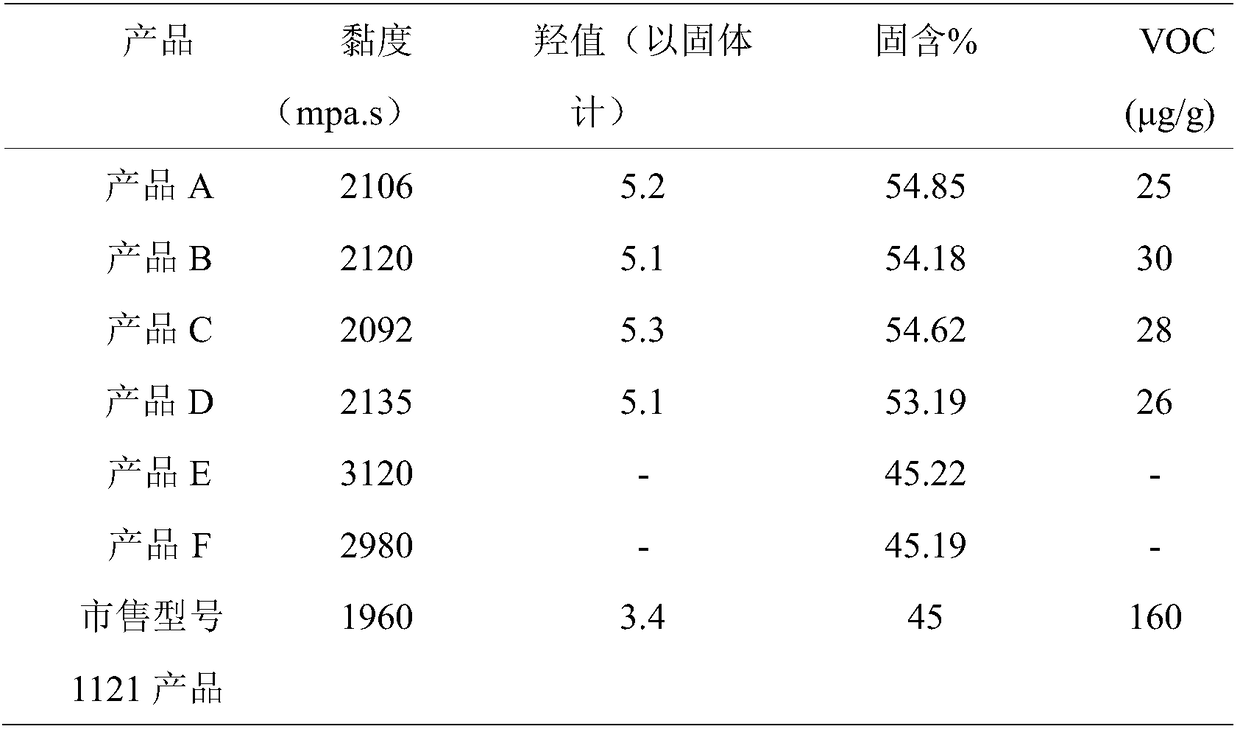

A technology of hydroxyacrylic acid and dispersion, applied in the field of materials, can solve the problems of gloss, fullness defects, high solvent content, poor water resistance, etc., and achieve the effects of narrow particle size distribution, simple preparation process, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Mix 2g of propylene oxide, 3.0g of butanediol, 2g of propylene glycol methyl ether acetate, 0.02g of potassium hydroxide, and 2.0g of unsaturated polyester, heat up to 140-145°C, and stir for 0.5-1h to obtain a reaction mixture;

[0021] (2) Add dropwise di-tert-butyl peroxide 0.5g and methyl acrylate 5g, methyl methacrylate 6g, butyl acrylate 4g in the reaction mixture that step (1) obtains, after the dropwise addition is completed and incubated for 1h, Continue to add dropwise the remaining 0.5g of di-tert-butyl peroxide, 5g of methyl acrylate, 6g of methyl methacrylate, and 4g of butyl acrylate. N, N dimethylethanolamine 4g neutralize, add appropriate amount of deionized water, stir and disperse for 1-2h, discharge, and obtain the polyether polyol-unsaturated polyester modified hydroxyl acrylic dispersion (hereinafter referred to as Product A).

Embodiment 2

[0023] (1) Mix 3g of epichlorohydrin, 5.0g of propylene glycol, 3g of propylene glycol methyl ether acetate, 0.03g of potassium hydroxide, and 3.0g of unsaturated polyester, heat up to 140-145°C, and stir for 0.5-1h to obtain a reaction mixture ;

[0024] (2) add dibenzoyl peroxide 1.0g and methyl acrylate 8g, methyl methacrylate 2g, hydroxyethyl methacrylate 5g, ethyl acrylate 5g in the reaction mixture that step (1) obtains, add After keeping warm for 1 hour, continue to add the remaining 1.0g of dibenzoyl peroxide, 8g of methyl acrylate, 2g of methyl methacrylate, 5g of hydroxyethyl methacrylate, and 5g of ethyl acrylate, and keep warm for 1-2 hours after adding Afterwards, lower the temperature to 75-80°C, add 6g of triethylamine to neutralize, add an appropriate amount of deionized water to stir and disperse for 1-2 hours, and discharge the material to obtain the polyether polyol-unsaturated polyester modified hydroxyl Acrylic dispersion (hereinafter referred to as produ...

Embodiment 3

[0026] (1) Mix 2.37g of propylene oxide, 3.66g of butanediol, 3g of propylene glycol methyl ether acetate, 0.02g of potassium hydroxide, and 2.21g of unsaturated polyester, heat up to 140-145°C, and stir for 0.5-1h to obtain reaction mixture;

[0027] (2) in the reaction mixture that step (1) obtains, drop di-tert-butyl peroxide 0.56g and acrylate monomer (the mass ratio of methyl acrylate, methyl methacrylate, butyl acrylate is 1: 1:1) 18.0g, after the dropwise addition is completed and kept warm for 1h, continue to add dropwise the remaining di-tert-butyl peroxide 0.56g and acrylate monomers (methyl acrylate, methyl methacrylate, butyl acrylate) The mass ratio is 1:1:1) 18.0g, keep warm for 1-2h after the dropwise addition, cool down to 75-80°C, add 5.4g of N,N dimethylethanolamine to neutralize, add appropriate amount of deionized water to stir and disperse After 1-2 hours, the material is discharged to obtain the polyether polyol-unsaturated polyester modified hydroxyacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com