Method for preparing large-area single-layer WSe2 monocrystals

A tungsten diselenide, large-area technology, applied in the field of microelectronics, can solve the problems of toxic precursors, high cost, and limited application of devices, and achieve the advantages of eliminating poisoning reactions, accurately controlling nucleation and growth processes, and reducing reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of a monolayer WSe with a size of 60 μm 2 ,

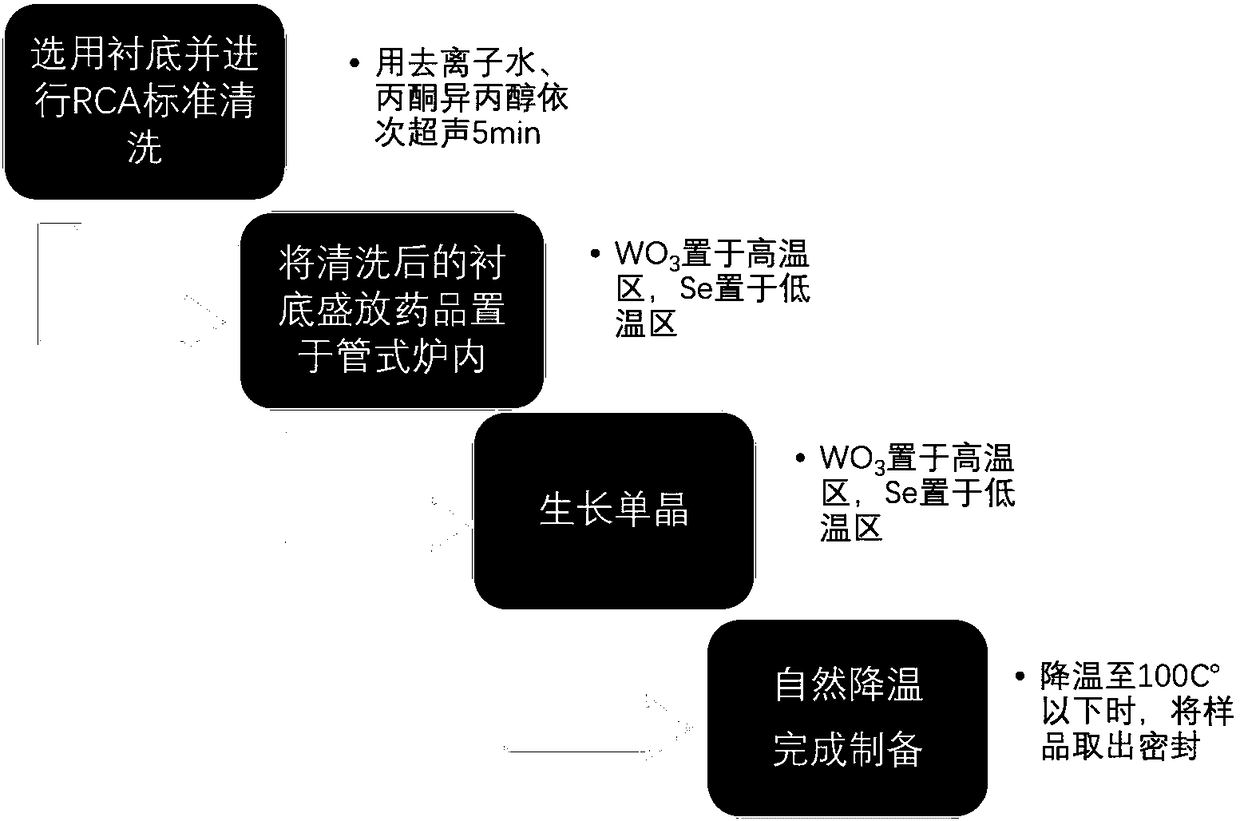

[0031] Step A, select the substrate and perform RCA standard cleaning.

[0032] Two silicon wafers with a layer of silicon dioxide deposited on silicon were selected as substrates, and the two substrates were ultrasonically cleaned with deionized water, acetone, and isopropanol for 5 minutes, and then dried with a nitrogen gun.

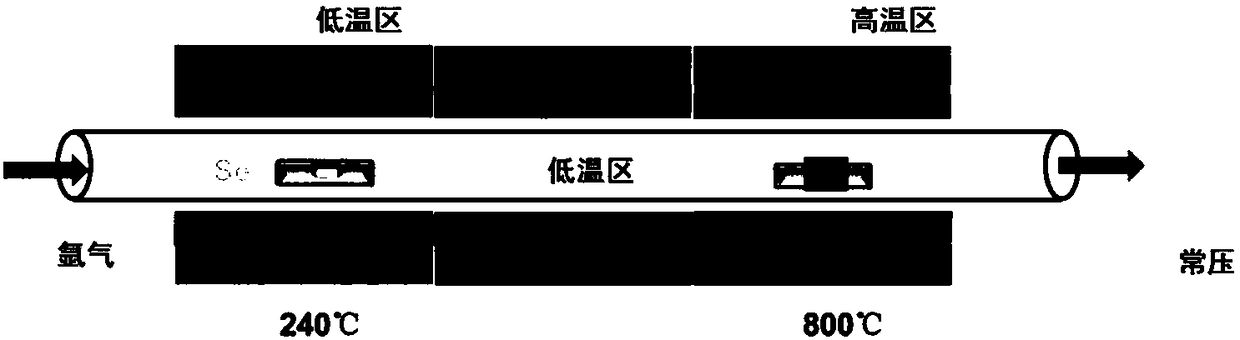

[0033] Step B, placing the cleaned substrate containing medicines in a tube furnace.

[0034] Prepare two quartz boats as a tungsten boat and a selenium boat respectively, dissolve 1 mg of NaCl in 5 mL of deionized water for later use, drop 20 μL of salt solution on the front of the first substrate with a pipette gun, and then heat it on a hot plate until the deionized water is completely vaporized;

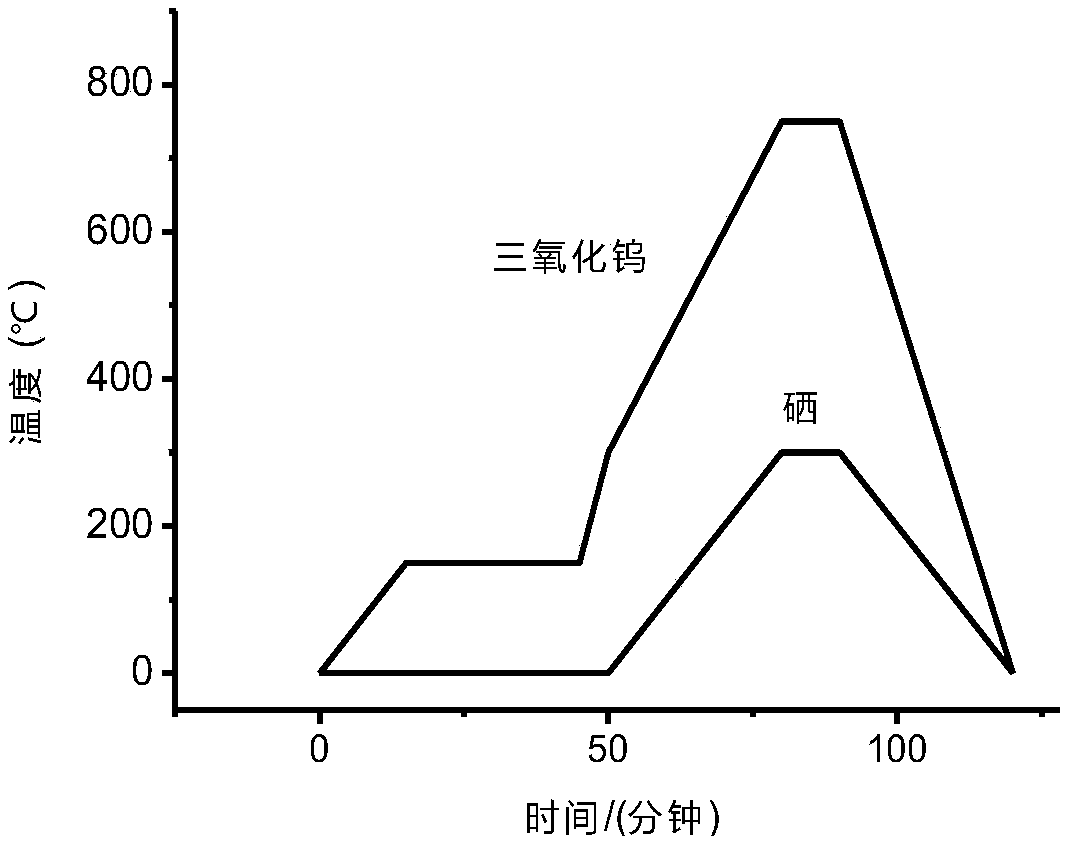

[0035] Put 10mg of WO in the center of the first substrate 3 After powdering, place it in a tungsten boat, cover the second substrate on the WO 3 1mm position above, and the...

Embodiment 2

[0044] Example 2: Preparation of monolayer WSe with a size of 30 μm 2

[0045] Step 1, select the substrate and perform RCA standard cleaning.

[0046] This step is the same as Step A of Example 1.

[0047] Step 2, placing the cleaned substrate containing medicines in a tube furnace.

[0048] First, prepare two quartz boats as a tungsten boat and a selenium boat respectively. Dissolve 100mg of NaCl in 5mL of deionized water for later use. Use a pipette to drop 2μL of saline solution on the front of the first substrate, and then place it on the hot plate. Heat until the deionized water is completely vaporized;

[0049] Then, put 10mg of WO in the center of the first substrate 3 After powdering, place it in a tungsten boat, cover the second substrate on the WO 3 10mm above the powder, then place the tungsten boat in the high temperature zone of the tube furnace;

[0050] Finally, 150 mg of Se powder was added to the selenium boat, and the selenium boat was placed in the lo...

Embodiment 3

[0058] Example 3: Preparation of a monolayer WSe with a size of 40 μm 2

[0059] Step 1, select the substrate and perform RCA standard cleaning.

[0060] This step is the same as Step A of Example 1.

[0061] Step 2, placing the cleaned substrate containing medicines in a tube furnace.

[0062] The first step is to prepare two quartz boats as a tungsten boat and a selenium boat respectively. Dissolve 5 mg of NaCl in 5 mL of deionized water for later use. Use a pipette to drop 20 μL of salt solution on the front of the first substrate, and then place the Heat on a hot plate until the deionized water is completely vaporized;

[0063] In the second step, place 10mg of WO in the center of the first substrate 3 After that, place it in a tungsten boat, cover the second substrate on the WO 3 5mm above the position, then place the tungsten boat in the high temperature zone of the tube furnace;

[0064] In the third step, 150mg of Se powder is added to the selenium boat, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com