Lead shearing device for brush micromotor and with outgoing line carbon brush

A shearing device and lead-out technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electric components, etc., can solve the problems of shortening the service life of scissors, inability to mass-produce, limit the thickness of lead wires and embedding depth, etc., and achieve Improve processing efficiency and yield, realize long-term continuous operation, and increase the effect of cutting the number of leads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

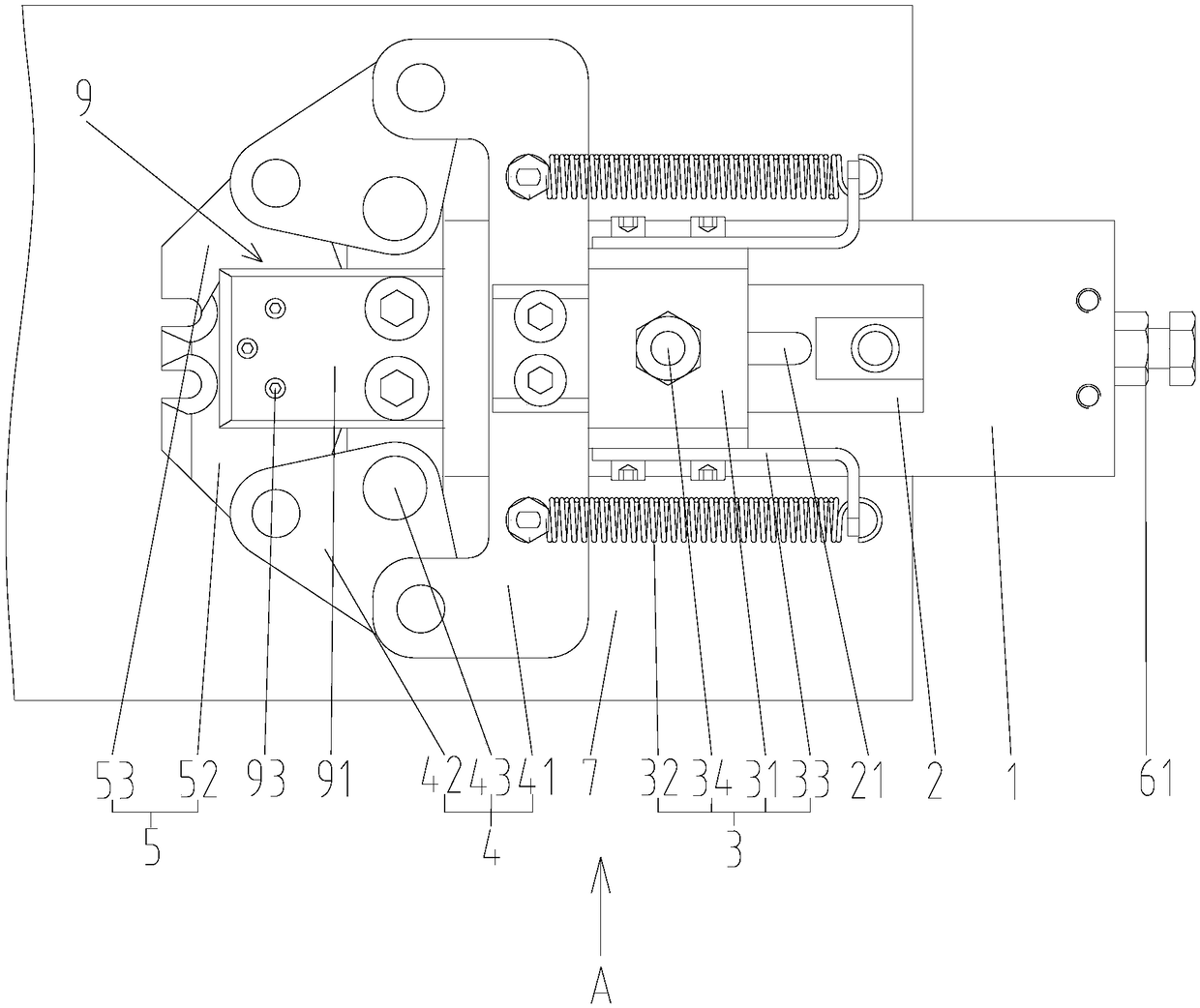

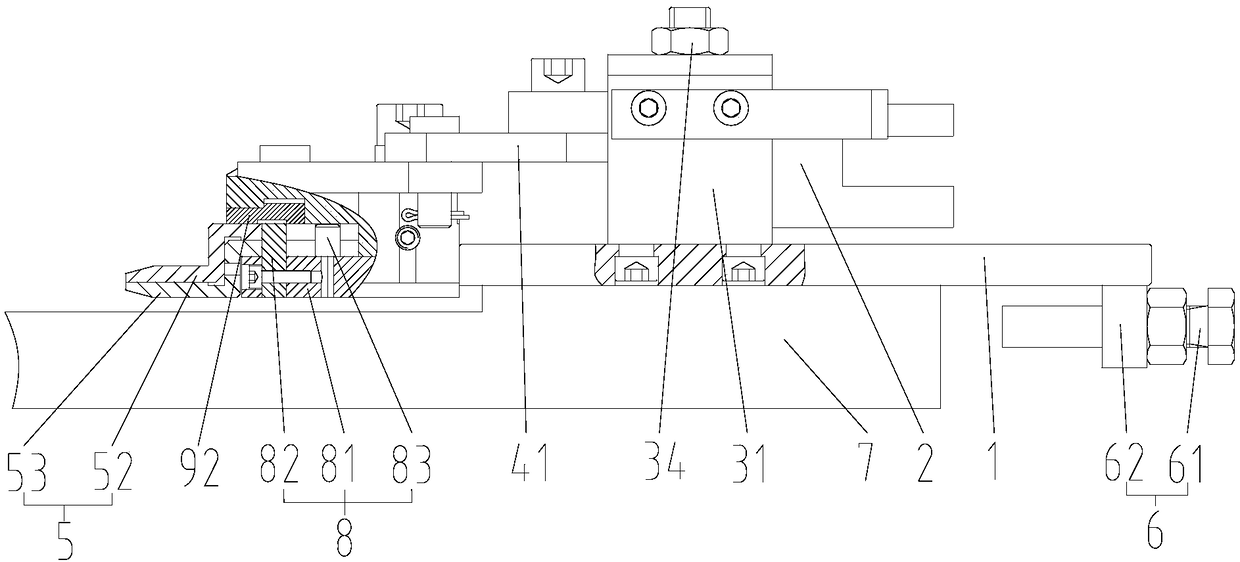

[0037] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

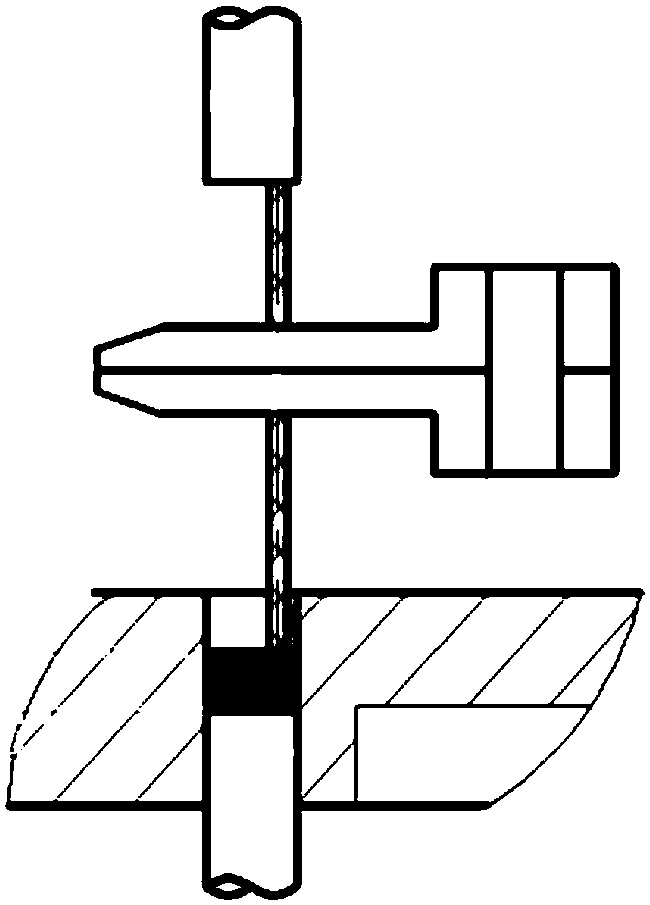

[0038] A lead wire cutting device with a lead wire carbon brush for a brushed micromotor, such as Figure 2-9 As shown, it includes a base plate 1, a power shaft 2, a guide mechanism 3, a transmission mechanism 4, a shear mechanism 5, a limit mechanism 6, a guide assembly 8, and a gap adjustment assembly 9. The guide mechanism 3 includes a guide block 31, an elastic member 32, Support 33, guide pin 34, transmission mechanism 4 comprises crossbeam 41, connecting triangular plate 42, large pin 43, shearing mechanism 5 comprises upper blade 52, lower blade 53, limit mechanism 6 comprises limit screw 61, screw mounting frame 62, The guiding assembly 8 includes a lower fixing plate 81 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com