Evaporation apparatus with self-cleaning function and capable of simultaneously processing two different types of waste liquid

A simultaneous treatment and evaporation device technology, applied in the direction of special treatment goals, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of investment and management costs, large amount of waste liquid, small discharge, etc., to achieve Make full use of waste heat, save energy, and easily discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is illustrated below in conjunction with embodiments and accompanying drawings.

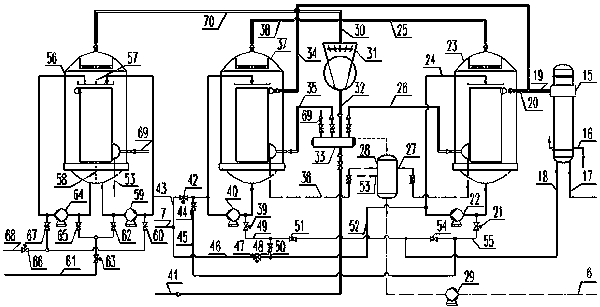

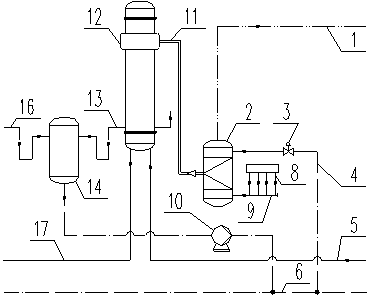

[0025] attached figure 1 In the embodiment, two evaporators of A evaporator 23 and B evaporator 37 are arranged in parallel, the secondary steam pipes 25 and 38 of A evaporator 23 and B evaporator 37 and the air inlet 30 of vapor compressor 31 connected. The discharge pipe 32 of the steam compressor 31 communicates with the cylinder 33 . The sub-cylinder 33 communicates with the A evaporator 23 and the B evaporator 37 with pipelines 26 and 35 respectively. It can be seen from the figure that valves are respectively arranged on the pipelines 26 and 35, and the sub-cylinder 33 is also connected with the fresh steam pipe 41 at the same time. Satisfy the power steam provided by the power boiler when the device starts working. The condensed water outlets of the A evaporator 23 and the B evaporator 37 are connected to the condensed water tank 28 through the condensed wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com