Circulating and mixing device in two-phase anaerobic digester for efficiently promoting acid production

An anaerobic digestion and mixing device technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of insufficient mixing power of the bottom reflux of the methane-producing phase, insufficient hydraulic stirring power of the acid-producing phase, Uneven distribution of velocity field and other problems, to achieve the effect of prolonging hydraulic retention time, improving acid production performance, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The creation of the present invention has been applied in the resource utilization and harmless treatment project of kitchen waste in Hefei City. The treatment project is 150m 3 The food waste is processed into biogas energy.

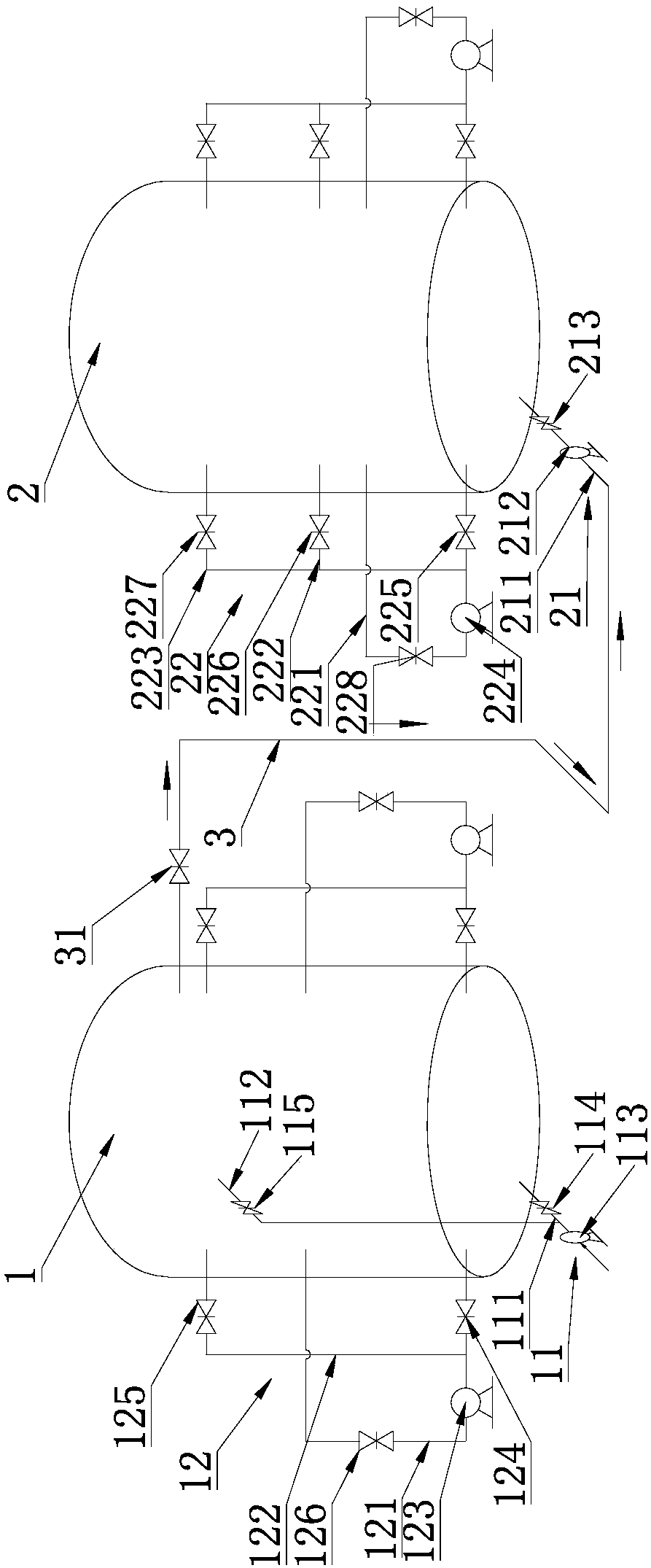

[0050] The acid-producing digester 1 of the biogas project adopts a fully mixed anaerobic reactor (CSTR), and the digester volume is 2500m 3 , with a diameter of 18m and a height of 10.5m; our company adopted a secondary acid-producing feed system 11 and a secondary acid-producing circulation system 12 in the acid-producing digester 1 of the food waste treatment project. A primary acid-generating feed valve 114 is set at a height of 1 m in the digester, and a secondary acid-generating feed valve 115 is set at a height of 9.9 m. Due to the high solid content of kitchen waste, the feeding method of the top feed pipe is adopted, and the bottom feed pipe is reserved for the long-term treatment of landfill leachate. Considering the relatively large di...

Embodiment 2

[0055] The creation of the present invention has also been applied in the resource utilization and harmless treatment project of kitchen waste in Taiyuan City. 3 The food waste is processed into biogas energy.

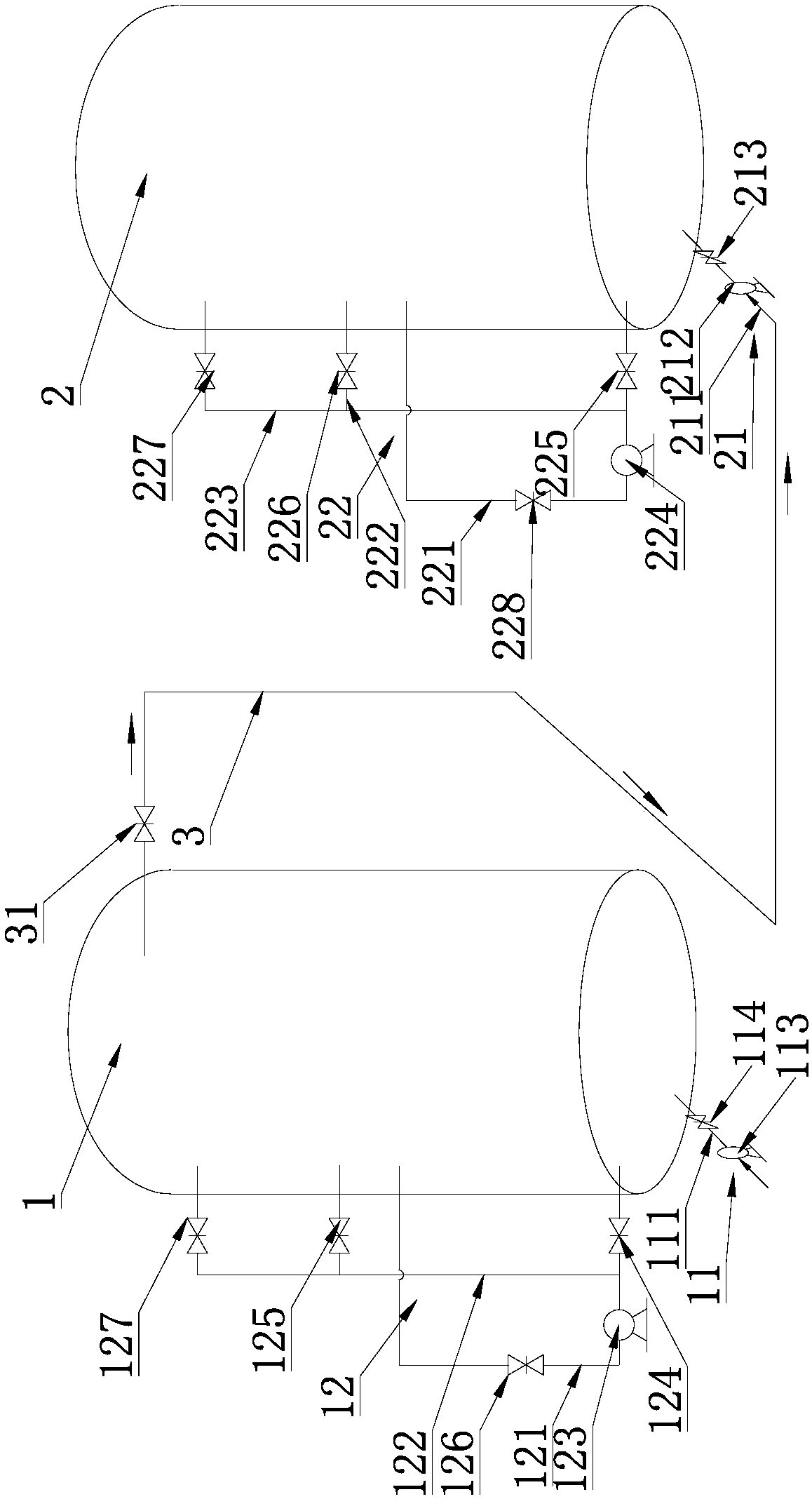

[0056] The acid-producing digester 1 of the biogas project uses two fully mixed anaerobic reactors (CSTR), with a digester volume of 1000m 3 , with a diameter of 9m and a height of 16m; considering the high solid content and high specific gravity of food waste, a primary acid production feed system 11 is used for top feeding, and a primary acid production feed system is set at a height of 15m in the digester. Feed valve 114. Combined with the small diameter-to-height ratio of the acid-generating digester 1, our company adopted a single-side three-stage acid-generating cycle system 12 in the acid-generating digester 1 of the food waste treatment project (see figure 2 ), an acid production circulation water intake valve 126 is set at a height of 9 meters, and a primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com