Synthesis method of dibutyl maleate

A technique for the synthesis of dibutyl maleate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as large amount of raw materials used, low product yield, and long production time , achieve the effect of shortening the reaction time of esterification, lowering the reaction temperature and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

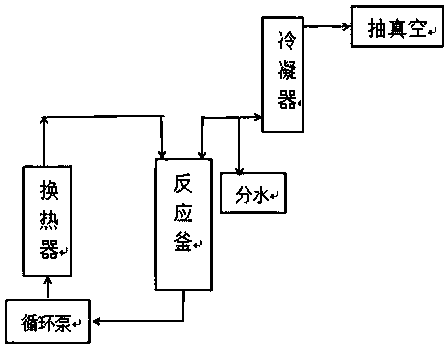

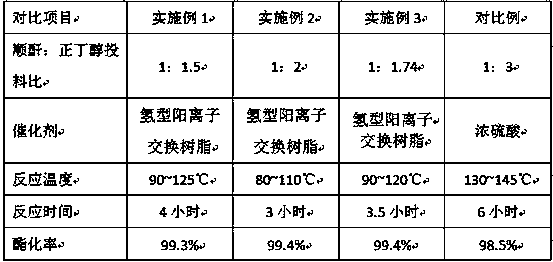

[0017] Such as figure 1 The schematic diagram of the technological process shown is operated, and in reactor, add 98kg maleic anhydride, 111kg n-butanol, 25kg hydrogen type cation exchange resin, heat up, open condenser, after being dissolved, open heat exchanger steam, Open the bottom valve of the reaction tank and the transfer pump, turn on the internal circulation, turn on the condenser to vacuumize, separate the produced water, control the reaction temperature in the tank at 90-125°C, react for 4 hours, distill, neutralize, and wash with water to obtain Product, testing product, the esterification rate is 99.3%.

Embodiment 2

[0019] Such as figure 1 The schematic diagram of the technological process shown is operated, and in reactor, add 98kg maleic anhydride, 148kg n-butanol, 35kg hydrogen type cation exchange resin, heat up, open condenser, after being dissolved, open heat exchanger steam, Open the bottom valve of the reaction tank and the transfer pump, turn on the internal circulation, and at the same time turn on the condenser to vacuumize, separate the produced water, control the reaction temperature in the tank at 80~110°C, react for 3 hours, distill, neutralize, wash with water, Obtain product, detect product, the esterification rate is 99.4%.

Embodiment 3

[0021] Such as figure 1 The schematic diagram of the technological process shown is operated, and in reactor, add 98kg maleic anhydride, 129kg n-butanol, 30kg hydrogen type cation exchange resin, heat up, open condenser, after being dissolved, open heat exchanger steam, Open the bottom valve of the reaction tank and the transfer pump, turn on the internal circulation, and at the same time open the condenser to vacuumize, separate the produced water, control the reaction temperature in the tank at 90~120°C, react for 3.5 hours, distill, neutralize, wash with water, Obtain product, detect product, the esterification rate is 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com