Rice hull plastic wood profile and preparation method thereof

A technology of plastic wood and profiles, which is applied in the field of rice husk plastic wood profiles and its preparation, which can solve the problems of low utilization of resources, environmental damage of waste plastics, large reserves of rice husk resources, etc., to reduce the time of shaping process and prolong the use Long life and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a specific embodiment, a preparation method of rice husk plastic-wood profiles at least includes the following steps:

[0039] Step S01. Recycling waste plastics to obtain high-density polyethylene;

[0040] Step S02. Weigh each component according to the above-mentioned component ratio;

[0041] Step S03. The weighed components are mixed, processed and granulated, and extruded.

[0042] In the above step S01, the regeneration treatment of waste plastics refers to sorting, crushing, cleaning, and drying the recovered waste plastics, and then transferring them to a high-speed mixer for thorough mixing, so that the above-mentioned embodiment of the present invention can be obtained. High-density polyethylene in the example.

[0043] Preferably, the mixing time is controlled within 6 minutes to 10 minutes, which can sufficiently allow the waste plastics to be mixed evenly, and if the time is too long, the power consumption will be increased.

[0044]In order to achie...

Embodiment 1

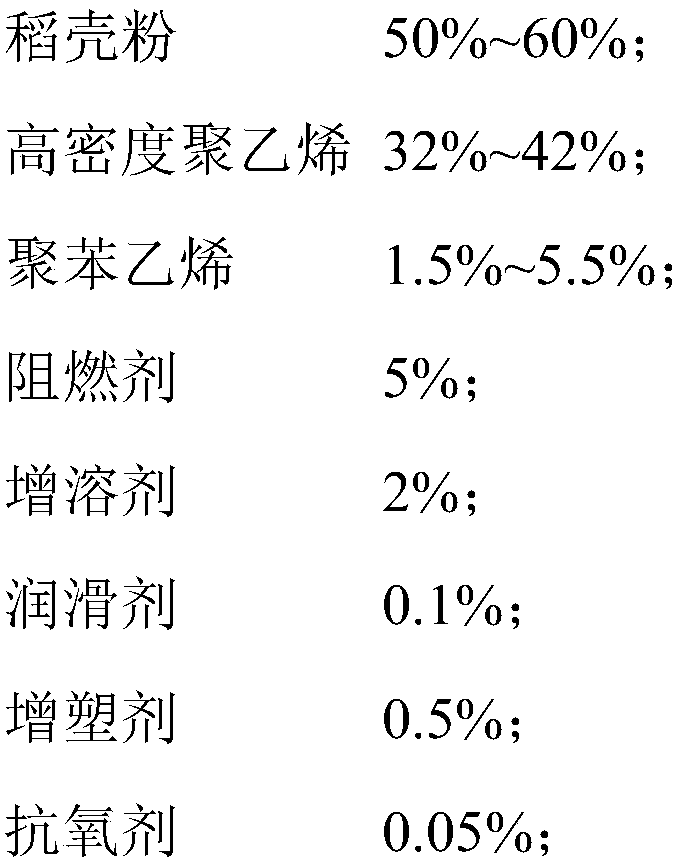

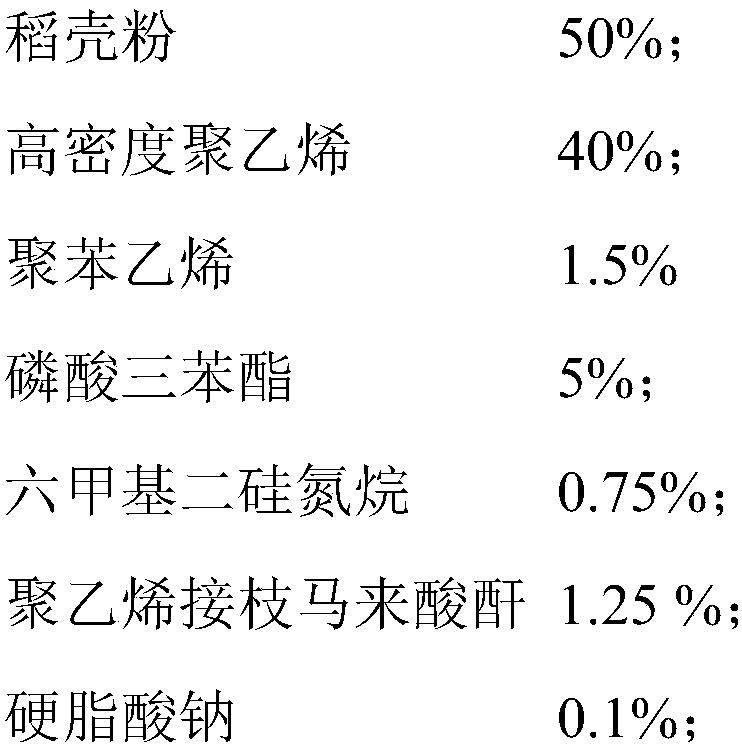

[0056] A rice husk plastic-wood profile, including the following components in mass percentage:

[0057]

[0058]

[0059] The balance is titanium dioxide;

[0060] Wherein, the high-density polyethylene is obtained from recycling waste plastics.

[0061] The preparation method of rice husk plastic-wood profile as described in embodiment 1, at least comprises the following steps:

[0062] Weigh each component as described in Example 1, add each component into a high-speed mixer respectively, add tetrahydrofuran accounting for 25% of the total material mass fraction, mix the materials, and then add 15% of the total material mass fraction of absolute ethanol, mixed, and then mixed at 125°C for 18 minutes, and then the mixed material was reacted and extruded into pellets in a twin-screw extruder. Cool and granulate.

[0063] Put the obtained pellets into a molding machine and extrude at 150°C to obtain rice husk plastic-wood profiles.

Embodiment 2

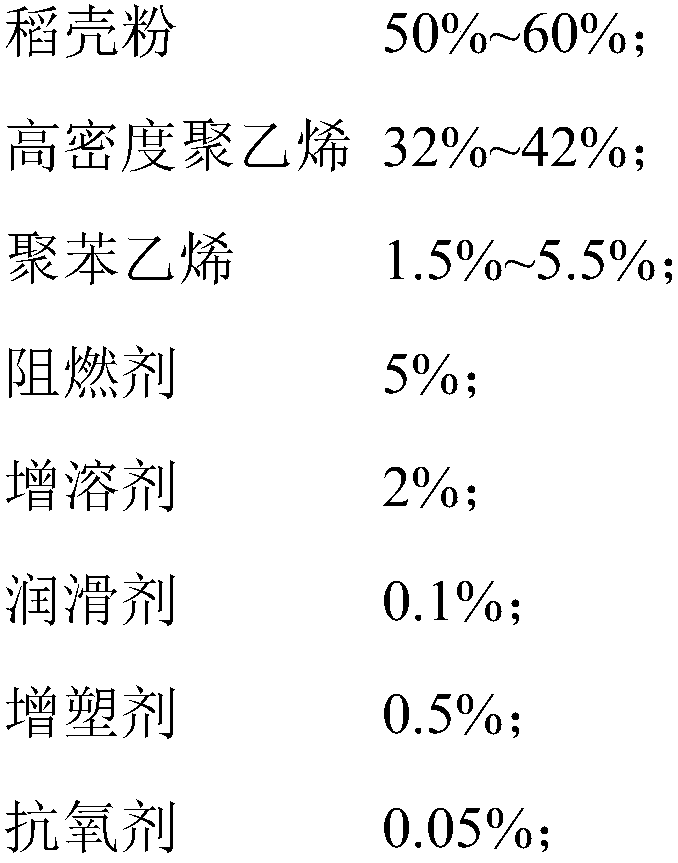

[0065] A rice husk plastic-wood profile, including the following components in mass percentage:

[0066]

[0067] The balance is titanium dioxide;

[0068] Wherein, the high-density polyethylene is obtained from recycling waste plastics.

[0069] The preparation method of rice husk plastic-wood profile as described in embodiment 2 at least comprises the following steps:

[0070] Weigh each component as described in Example 2, add each component into a high-speed mixer in turn, add tetrahydrofuran accounting for 40% of the total material mass fraction, mix the materials, and then add 20% of the total material mass fraction of absolute ethanol, mixed, and then mixed at 135°C for 8 minutes, and then the mixed material was reacted and extruded into pellets in a twin-screw extruder. The melting temperature of the screw was 195°C, and the speed was 175r / min. The material is cooled and granulated.

[0071] Put the obtained pellets into a molding machine and extrude at 155°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com