Polysiloxane insulation coating for railway cantilever and preparation method thereof

A polysiloxane, insulating coating technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of long-term creep, difficult handling and installation, cumbersome and other problems, and achieve the effects of improved electrical performance, good hydrophobicity, and extended maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

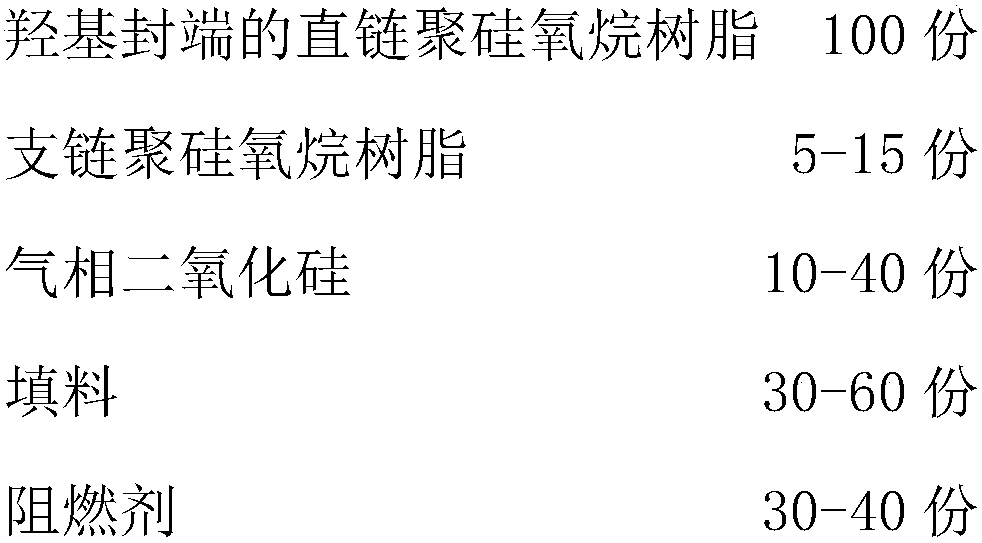

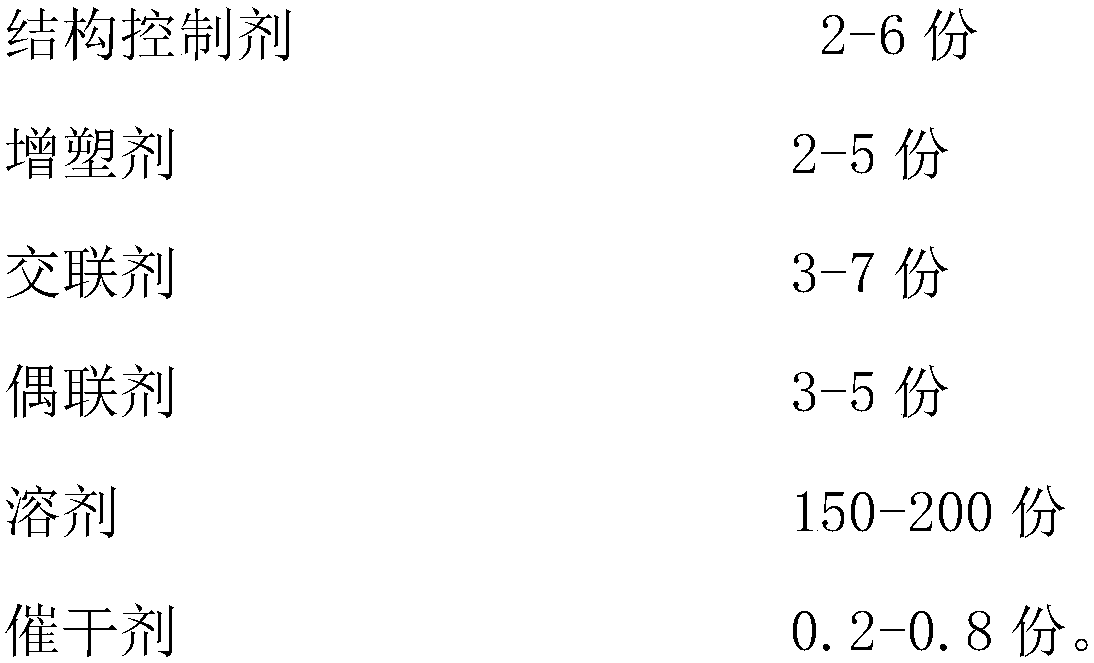

[0023] The invention provides a kind of polysiloxane insulating paint and preparation method thereof on the railway arm, the weight component of this polysiloxane insulating paint is as follows:

[0024]

[0025]

[0026] The present invention also provides a kind of preparation method that is used for the polysiloxane insulation paint on the railway arm, comprises the following steps:

[0027] S1. Add hydroxyl-terminated linear polysiloxane resin, hydroxyl branched polysiloxane resin, N20, aluminum hydroxide, and NP-10 into the kneader and heat up to 180°C for 3 hours under vacuum and kneading (vacuum degree is 0.08 MPa); S2, when the temperature of the material drops below 120°C, add small molecule hydroxyl silicone oil and continue kneading for 30 minutes; S3, grind the kneaded material to below 45 μm by a three-roll mill; S4, add the ground material to the mixing and dispersing machine Then add 120# solvent oil and stir to disperse evenly, then add methyl tributylket...

Embodiment 2

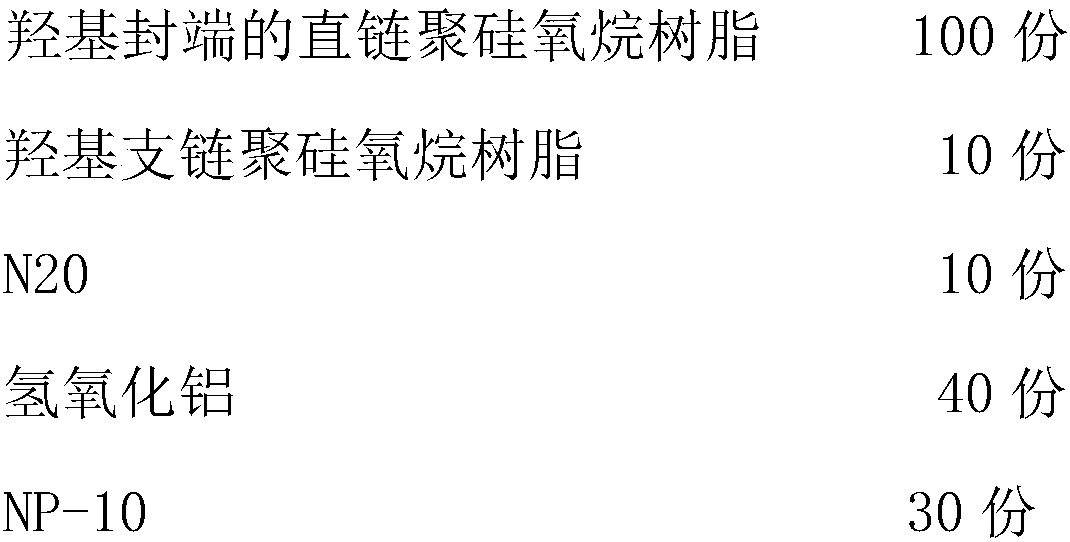

[0029] The invention provides a kind of polysiloxane insulating paint and preparation method thereof on the railway arm, the weight component of this polysiloxane insulating paint is as follows:

[0030]

[0031]

[0032] The present invention also provides a kind of preparation method that is used for the polysiloxane insulation paint on the railway arm, comprises the following steps:

[0033] S1. Add hydroxyl-terminated linear polysiloxane resin, hydroxyl branched polysiloxane resin, R972, aluminum hydroxide, and composite ceramic powder into the kneader and heat up to 180°C for 3 hours under vacuum and kneading (vacuum degree: 0.08MPa); S2, when the temperature of the material drops below 120°C, add small molecular hydroxy silicone oil and continue kneading for 30 minutes; S3, grind the kneaded material to below 45 μm by a three-roll mill; S4, add the ground material to mix and disperse Then add naphtha into the machine and stir to disperse evenly, then add methyl tri...

Embodiment 3

[0035] The invention provides a kind of polysiloxane insulating paint and preparation method thereof on the railway arm, the weight component of this polysiloxane insulating paint is as follows:

[0036]

[0037]

[0038] The invention provides a kind of polysiloxane insulating paint and preparation method thereof on the railway arm, the weight component of this polysiloxane insulating paint is as follows:

[0039] S1. Add hydroxyl-terminated linear polysiloxane resin, hydroxyl branched polysiloxane resin, R8200, alumina, and composite ceramic powder into the kneader and heat up to 180°C for 3 hours under vacuum and kneading (vacuum degree is 0.08 MPa); S2, when the temperature of the material drops below 120°C, add small molecule hydroxyl silicone oil and continue kneading for 30 minutes; S3, grind the kneaded material to below 45 μm by a three-roll mill; S4, add the ground material to the mixing and dispersing machine Then add naphtha and stir to disperse evenly, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com