Small turbojet engine adopting self-acting air bearing and rotor support structure

A turbojet engine and supporting structure technology, applied in the directions of engine components, engine lubrication, turbine/propulsion lubrication, etc., can solve the problems of temperature not exceeding 180 ° C, not exceeding 30 hours, expensive maintenance, etc., to achieve production The effect of the same cost, lower operating temperature and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

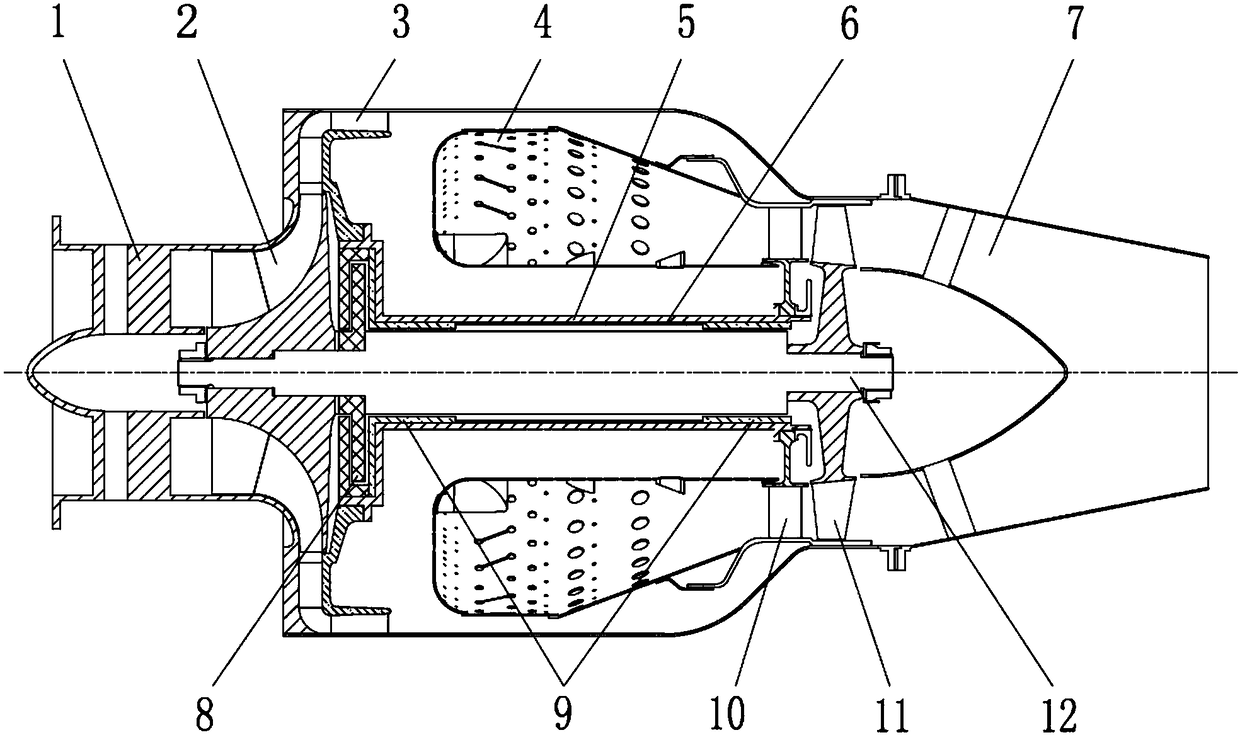

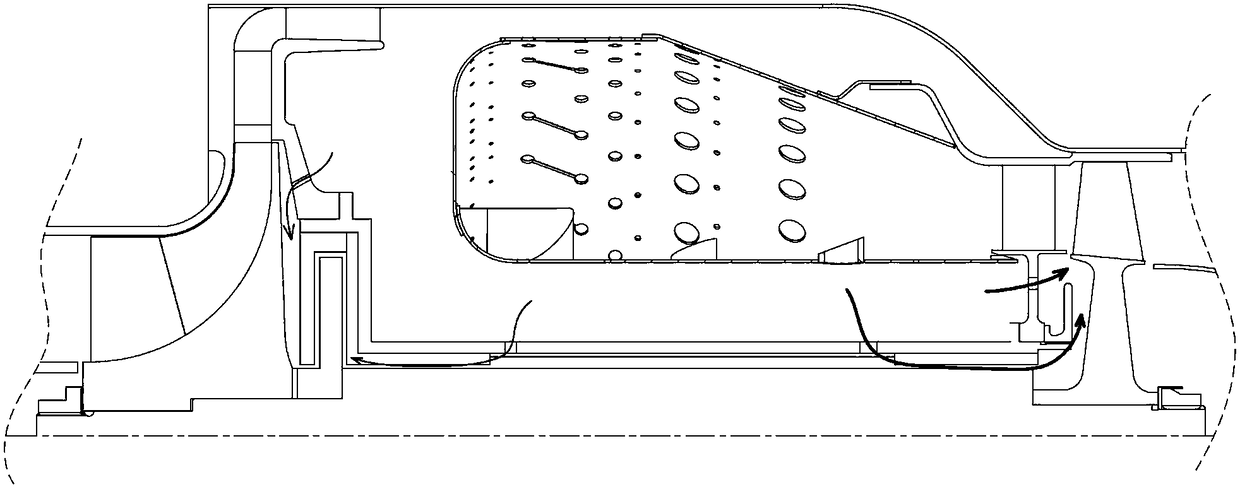

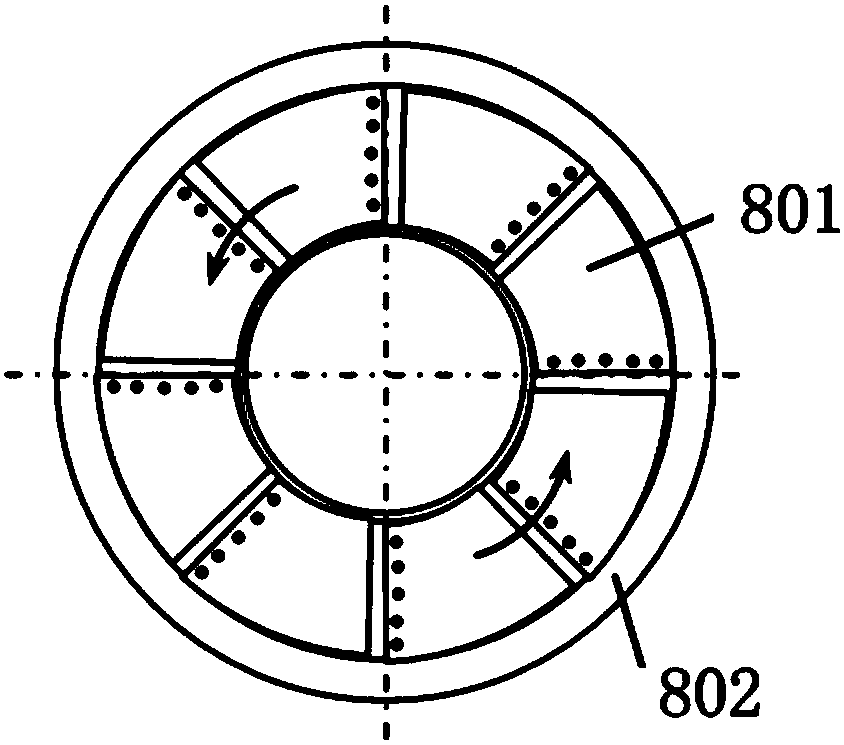

[0028] Such as figure 1 , 2As shown, the engine rotor support structure of this embodiment is suitable for small turbojet engines, and uses dynamic pressure air bearings to support the engine rotor system, including compressor casing 1, centrifugal impeller 2, diffuser 3, combustion chamber 4, bearing support Seat 5, spacer ring 6, tail nozzle 7, axial thrust bearing 8, radial bearing 9, guider 10, turbine rotor 11, central shaft 12. Among them, the centrifugal impeller 2 is arranged at the front end of the central shaft 12, the turbine rotor 11 is arranged at the rear end of the central shaft 12, and the front and rear radial bearings 9 are installed between the bearing support 5 and the central shaft 12 to bear the diameter of the rotor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com